|

<Previous

Next>

In all my years of repairing and restoring

old radios, I have never had the occasion to re-string a dial cord. There are many

variations on dial cord construction and diameter, but there are even more variations

in that way the path around the tuning shaft, tuning elements, and indicator dials

are implemented. Larger radios with lots of room in them are relatively easy to

re-string and usually take a fairly straightforward path, but smaller portable multiband

radios like my 1970's-vintage Realistic (Radio Shack, Tandy) Patrolman−50

are a bit of a challenge, as I found out recently. A Web search on recommendations

for how to replace dial cords results mostly in frustrated handymen who have seemingly

given up on the job. It is easy to understand why, especially on a ridiculously

complicated routing scheme. In all my years of repairing and restoring

old radios, I have never had the occasion to re-string a dial cord. There are many

variations on dial cord construction and diameter, but there are even more variations

in that way the path around the tuning shaft, tuning elements, and indicator dials

are implemented. Larger radios with lots of room in them are relatively easy to

re-string and usually take a fairly straightforward path, but smaller portable multiband

radios like my 1970's-vintage Realistic (Radio Shack, Tandy) Patrolman−50

are a bit of a challenge, as I found out recently. A Web search on recommendations

for how to replace dial cords results mostly in frustrated handymen who have seemingly

given up on the job. It is easy to understand why, especially on a ridiculously

complicated routing scheme.

Realistic Patrolman−50 Multiband Radio

Broken Dial Cord

New Dial Cord Installed

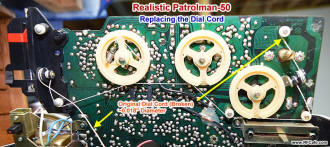

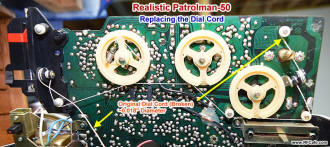

My only guess as to the need for the multiple pulleys and specific number of

wraps around each is because of the need to maintain very solid contact while tuning

four separate variable capacitors to handle the AM, FM, Aircraft, VHF Low and High,

and UFH bands. In the olden days, repair shops usually had documentation from the

manufacturer showing how to re-string the dial cord. If all that is needed is a

couple wraps around the tuning knob shaft and once around a variable tuning capacitor,

it would be a no-brainer. The Patrolman−50, however, has a unique configuration

with a set of pulleys (aka idler, bobbin, or sheave) that each has a dual-diameter

bobbin bound together on the shaft. This creates a situation where as the pulley

rotates, the dial cord winds onto or off of (depending on direction of rotation)

the larger diameter pulley at a greater rate then that of the smaller diameter pulley.

After a few failed attempts at re-stringing, I figured out that this setup helps

keep the dial cord tight around the tuning capacitor pulleys while providing slack

on the back side to prevent binding. It facilitates keeping the entire path at the

proper tension. After a few cycles back and forth between the tuning extremities,

the spring at the end of the dial cord settled into an optimal position.

Fortunately for me, the Patrolman−50's dial cord broke along the path near to

where it connected to the indicator. That allowed me to photograph the original

configuration of the dial cord path before removing it for replacement. I also made

a hand sketch of the path with direction and number of turns around each point.

Unfortunately, though, it was at those darn dual diameter pulleys where the cord

unwound enough to be uncertain about the number of turns on each bobbin. That's

where the difficulty arose with re-winding because there was just enough room on

each section to hold only the required number of turns or else the cord would stack

on itself and bind. It took probably four or five rounds of trial and error to figure

it out. With great relief I finally got the dial cord turns to fill and empty the

bobbins in the correct ratio, and then magically the entire tuning path worked without

any slippage. Actually, the system is designed to accommodate some slip at the ends

of the travel in order to prevent some dummkopf from breaking the cord or a component

while continuing to crank the tuning knob after reaching the end of the tuning range

(no, that's not how I broke it).

Authentic dial cord can be purchased online, but it costs about ten dollars for

a few feet - not enough to allow for screwing up a couple times. Once you tie off

the ends and try the operation, you cannot re-use the dial cord since there will

not be enough to work with on another attempt, and you cannot tie a knot in it.

Yes, I tried a temporary knot, but that did not work for me. Anyway, since the original

dial cord measured about 0.018" in diameter, I bought some 100-pound-test braided

SpiderWire (SCS100BC-200) that is almost exactly the same size. That stuff is really

expensive, and the smallest spool I could find was 200 yards, so there is a lot

left over. I'm not a fisherman and will never use that much, so if you need some

for a dial cord, let me know and I'll send you a few yards for just the cost of

postage. Since SpiderWire is fairly slick, I ran what I used past some 600 grit

sandpaper a few times and then cleaned it with isopropyl alcohol. I also used some

of Melanie's violin bow rosin to make it a bit stickier where it wraps around the

tuning knob shaft. The radio tunes very easily with the setup.

Dial Cord Routing (left side)

The Patrolman−50 has a jack for connecting an external antenna, which helps for

the VHF and UFH bands.

Right Side

|

Dial Cord Routing (right side)

Patrolman−50 Radio Bands:

AM: 540-1620 kHz

FM: 88-108 MHz

VHF Air: 108-135 MHz

VHF Hi: 144-174 MHz

VHF Lo: 30-50 MHz

UHF: 450-512 MHz

Back

|

Printed Circuit Board (Component Side)

Applying Violin Rosin to Dial Cord

Left Side

|

Posted September 10, 2018

|

"

"