|

January 1960 Electronics World

Table of Contents

Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

Today's electronics and

RF magazines tend to cater to engineers and managers, as opposed to technicians

and hobbyists. That's not to say that techs do not benefit from the material

presented, but that information is typically concerned with new product and

system design with little attention paid to troubleshooting and maintenance. The

predecessors to modern magazines much more often included articles on the

latter. Publications like Popular Electronics, being intended for

hobbyists, featured useful quizzes, "how to" articles, and troubleshooting tips

along with product reports and an occasional design methodology piece.

Electronics World, the predecessor to Popular Electronics, was

more of an equal split between professional and hobby themes. This particular

article tests the reader's knowledge of capacitors by proposing circuit failure

examples which are due to a malfunctioning capacitor and challenges him/her to

determine the likely cause based on observed symptoms.

Do You Know Enough About Capacitors?

By Sol Heller By Sol Heller

In these "simple" troubleshooting and replacement problems, would you proceed

correctly every time?

Do you feel there is nothing to replacing a defective capacitor except substituting

a similar unit?

Or do you have the capacity to recognize that there is more to a capacitor than

capacitance? Here is a quiz that may turn up some surprises for you. On the other

hand, getting all the answers right should give you a charge.

Question: A service technician hesitates to use a 0.01-μf

paper capacitor as a replacement because it has been lying around (unused) on his

shelf for ten years. Is his hesitation justified?

Answer: With the exception of electrolytic units, capacitors

deteriorate only during the time voltage is applied to them. The technician should

show no hesitation about using the capacitor. Besides, if he does so little business

that he still stocks a component he bought ten years ago, how can he afford to do

anything else?

Question: Under what conditions is it preferable to connect

an audio power output tube plate capacitor between plate and screen, rather than

plate and ground, or plate and cathode?

Answer: When a capacitor of the proper working voltage is not

available, or when concern is felt, for some reason, regarding the possibility of

a breakdown in the replacement capacitor, the plate-to-screen connection may be

used. The d.c. voltage across the capacitor is much smaller in the latter case than

it would be if the negative end of the capacitor were connected to ground, or to

the cathode of the audio power output tube.

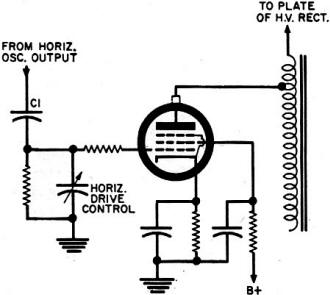

Fig. 1 - If you're alert, you would know what to look out for

in replacing C281.

Fig. 2 - The proper replacement for one capacitor here can lick

vertical drift.

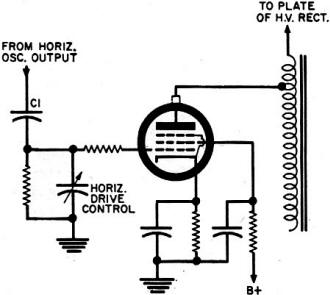

Fig. 3 - A common procedure used in replacing C1 could

cause later difficulty.

Question: Can a conventional 10-μf electrolytic capacitor be

used to replace L; in the C281 in the circuit shown in Fig. 1?

Answer: No. When the receiver is fully warmed up, the negative

side of the capacitor is at "B+" potential, while the positive side is at the higher

boosted "B+" voltage. A conventional capacitor could be used if this condition prevailed

at all times, since the negative side of the capacitor would always be at a lower

potential than the positive side. The condition does not prevail at all times, however.

During the time the receiver is warming up, the boost voltage is lower than "B+."

The negative side of C281 is consequently connected to a higher positive

potential than the positive side. The capacitor operates at this reversed polarity

for about 10 to 15 seconds. A conventional electrolytic capacitor would bite the

dust prematurely if exposed to such topsy-turvy conditions. A special semi-polarized

unit is used by some set makers and available from them.

Question: C1 in the vertical oscillator circuit shown

in Fig. 2 is a ceramic disc coupling capacitor. What type of capacitor can be substituted

for it when vertical drift is a problem, and tests have indicated that the vertical

oscillator tube is not responsible?

Answer: Substitution of a silver mica capacitor would be a logical

procedure. The mica type has a very high electrical stability. A 1000-μμf. unit,

for instance, will exhibit a capacitance change of less than .1% over a frequency

range extending from low frequencies to 2 mc. The effect of a 1°C change in temperature

is a change in capacitance of only 60 parts in a million. The tolerance of the replacement

capacitor is not important - the vertical hold control setting will produce the

correct frequency of operation even if the capacitor is 10 or 20% off its nominal

capacitance. The important thing is that the capacitance, whatever it is, doesn't

change with temperature.

Question: What harm, if any, is there in using a somewhat larger

value of capacitance than called for in replacing the coupling capacitor between

horizontal oscillator and horizontal output tube (C1, Fig. 3).

Answer: A larger value of coupling capacitance will increase

the amount of horizontal sweep signal applied to the horizontal output tube. The

horizontal drive control may have to be reset to some point close to one end of

its range, leaving an insufficient margin for readjustments necessitated by aging

or replacement of tubes or components in this circuit.

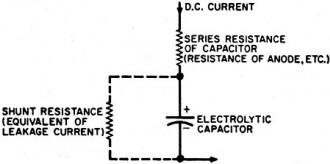

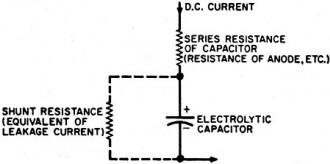

Question: Why is it undesirable to mount an electrolytic capacitor

in an area where considerable heat is likely to develop during receiver operation?

Answer: Heat is bad because it promotes drying out of the electrolyte.

This increases the series resistance offered by the capacitor; and the power factor

(ratio of resistance to impedance in the capacitor) goes up in consequence. A higher

power factor is undesirable, since larger I2R losses occur across the

increased resistance of the capacitor, and produce still further heating of the

unit. Heat also tends to increase the leakage current of the capacitor (see Fig.

4), which promotes greater I2R losses in the capacitor, and additional

heating of the unit.

Excessive heating spells death to electrolytic capacitors. In some types, every

10°C increase in temperature causes a 50% decrease in life expectancy; others are

less affected by temperature. In general, however, keeping cool is as important

for capacitors as it is for people.

Question: A technician, in replacing a power supply electrolytic

capacitor that has failed prematurely, decides to leave off the insulating cardboard

that was present around the original unit. Does this procedure make sense?

Answer: It does. The cardboard insulation prevented the capacitor

from dissipating heat adequately, and could be responsible for premature failure.

But watch for exposed voltage.

Question: What kind of electrolytic capacitor will function

more satisfactorily than other kinds under high-temperature conditions?

Answer: A capacitor that has a hermetically sealed metal can

for its container. This construction minimizes loss of electrolyte, and therefore

increases life expectancy. Any capacitor with a voltage rating 50 to 100 volts higher

than the operating voltage can be used at temperatures up to 185°F. Temperatures

in excess of 140°F may damage a conventional capacitor if its voltage rating

is not much above the operating voltage.

Question: Are there any applications in which it would make

a difference whether an electrolytic capacitor was fabricated with an etched-foil

anode or a plain-foil anode?

Fig. 4 - An improperly mounted electrolytic may start a vicious

trouble cycle.

Fig. 5 - Special problems go with special units, like (A) the

ceramic feed-through and (B) parallel-lead tubular.

Answer: Yes. Dry electrolytic capacitors have anodes made of

plain, etched, sprayed, or fabricated foil. An etched-foil anode is one that has

been made very rough by special processing. The resultant surface undulations give

the anode (which forms one plate of the capacitor) a much larger effective area.

The electrolyte (which forms the second plate of the capacitor) follows the undulations.

The capacitor, in consequence, has a much larger capacitance than a plain-foil unit

of the same size would have, permitting compactness.

However, an etched-foil capacitor will have a considerably higher total impedance

than a plain-foil equivalent, making the former inferior for certain applications.

A unit that does not have an etched foil would be preferable for bypassing and decoupling

in audio-frequency and vertical sweep circuits. The catalogues of parts supply houses

are often useful in determining whether a specific electrolytic capacitor does or

does not use an etched-foil anode.

Question: What effects, if any, do low temperatures have on

electrolytic capacitors?

Answer: For most conventional types, the capacitance decreases

rapidly below temperatures of -5°C. We can conceive of a situation where a battery

portable in which an electrolytic capacitor has been replaced is returned to the

service technician for further work because it didn't operate satisfactorily outdoors

in very cold weather. This temporary condition clears up when the receiver and its

owner sensibly return to a comfortable position by the fireside, or when the weather

gets a little warmer. If necessary, higher-cost tantalum capacitors may be used.

Some of these are rated for operation at -55°C, or even lower.

Question: In the case of a ceramic feed-through type of capacitor

(as shown in Fig. 5A), are there any visual indications that might point to the

need of replacement?

Answer: This type should be replaced if the silver-coated surface

is peeled, or if the ceramic is cracked, or if the center conductor of the unit

is loose.

Question: Does it make a difference in which position an electrolytic

capacitor is mounted?

Answer: It may, especially if the unit is a wet electrolytic.

An incorrect mounting position may reduce the effective capacitance. The unit should

be mounted in an upright position in such a way that the vent (for escaping gas)

is unobstructed.

Question: True or False: When an electrolytic capacitor begins

to cause circuit malfunction, it is always necessary to replace it.

Answer: False. Take the case where the only change causing the

trouble is an increase in r.f. impedance of the unit, impairing its ability to bypass

higher frequencies. Bridging it with a non-electrolytic type of smaller value but

of the proper voltage rating (for example, a 0.1μf paper unit) will generally eliminate

the trouble.

Question: True or False: If a replacement filter capacitor doesn't

function properly as soon as it is put into a radio (i.e., hum is heard), it should

be replaced immediately.

Answer: False. It should be given a chance to reform. When an

electrolytic capacitor has been idle for several months, initial leakage current

may be high enough to introduce hum because the component has deformed while not

in use. If the receiver is left in operation for 20 minutes or so, the capacitor

will generally be restored to normal functioning.

Question: True or False: When a capacitor that is mounted on

a printed board is to be replaced, it may become necessary to consider more of its

characteristics than is ordinarily the case.

Answer: True. The physical configuration may become important

in addition to the electrical properties. Take the paper tubular capacitor with

phenolic case shown in Fig. 5B. Parallel leads permit the unit to be plugged into

a printed board, after which it is soldered in place. It would be quite difficult

to fit a conventional capacitor of the same nominal value with axial leads into

the proper space, in most cases.

Posted May 9, 2019

|

By Sol Heller

By Sol Heller