|

July 1965 Electronics World

Table of Contents

Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

The July 1965 issue of

Electronics World magazine contained articles on many types of capacitors

being used at the time. As of this writing I have posted the articles on paper

and plastic film capacitors. Still to come are mica, ceramic, and glass. Newer

dielectric formulations have been developed since then, with some being

improvements on existing types and others being either rarely or never used back

then. Notably missing in the capacitor formats are distributed element on

substrate, semiconductor, and air (vacuum). Construction and parameters for both

polarized and non-polarized electrolytic capacitors are addressed by Mr. H. Nieders, of the

Mallory Capacitor Company (now

Duracell).

Electrolytic Capacitors

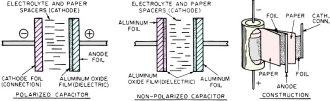

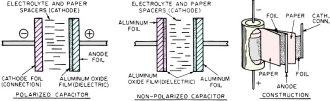

Fig. 1 - Cross-section of (A) polarized and (B) non-polarized

aluminum electrolytics. (C) shows the construction details.

By H. Nieders

Mallory Capacitor Co., Div. of P.R. Mallory & Co., Inc.

Widely used where large capacitance and small size are required, electrolytics

are among our most important capacitor types. Aluminum and tantalum units are covered.

In 1964 some 2,305,000,000 units of all types of capacitors were produced and

sold. Of this total, electrolytic capacitors accounted for 249,000,000 units. In

terms of dollars, this amounted to about $344,000,000 for all capacitors and $127,000,000

for electrolytic types. These figures would seem to indicate that electrolytic capacitors

are expensive - but this is not true.

Electrolytic capacitors actually save money, space, and weight when used properly

within their limitations and the limitations of the circuitry employed. The "why"

of electrolytic capacitors is economy; the "when" is a matter of application.

Generally, electrolytic capacitors can be divided into two basic types by the

nature of the base-oxidizable metal used. This is usually either aluminum or tantalum.

There are other usable metals, but these two yield relatively large capacitance

per unit of volume at an economical price. A tantalum capacitor costs more money

but saves more space and weight than an aluminum unit. There are other technical

differences, but the two types are more easily understood when reviewed separately.

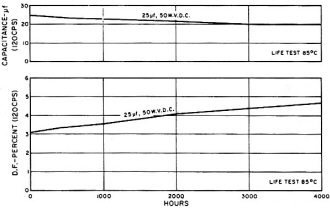

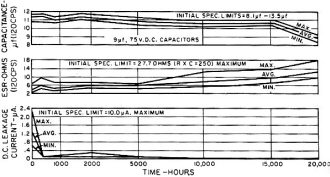

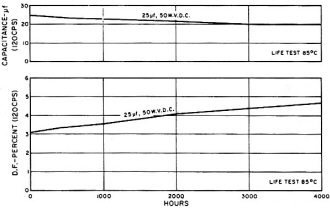

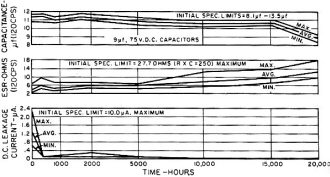

Fig. 2 - A typical life test for one specific type of industrial-grade

can-type aluminum electrolytic with axial leads.

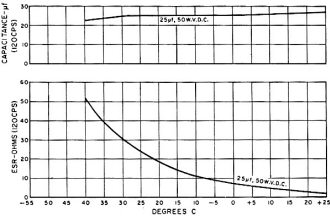

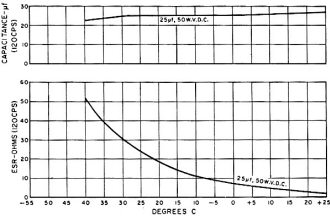

Fig. 3 - Typical stability of electrical characteristics vs.

temperature for same type of industrial-grade capacitor.

Fig. 4 - Typical life test for one particular type of premium-grade

can-type aluminum electrolytic unit with axial leads.

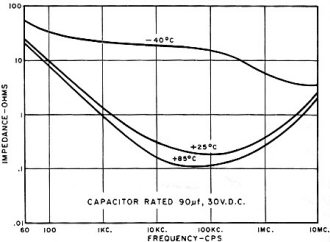

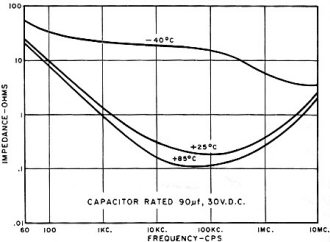

Fig. 5 - Typical impedance vs. frequency at various temperatures

for same type of premium-grade can-type aluminum electrolytic.

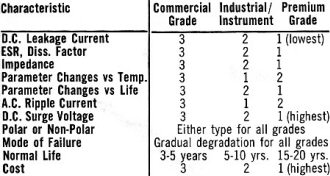

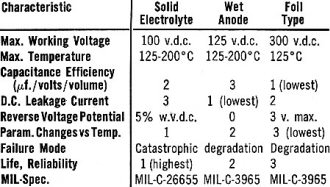

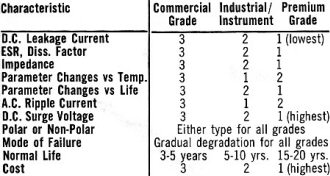

Table 1 - Ranking of some of the more important characteristics

of the three major types of aluminum electrolytic capacitors.

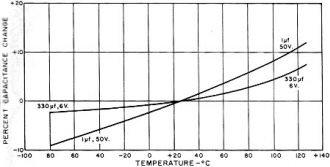

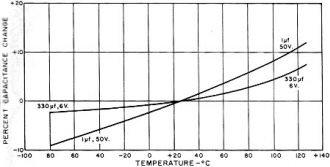

Fig. 6 - Typical capacitance change with temperature for one

specific type of solid-electrolyte tantalum electrolytic.

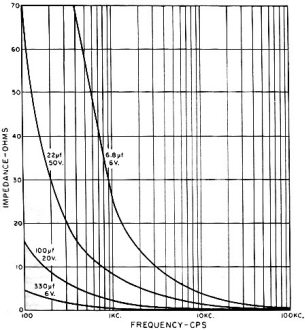

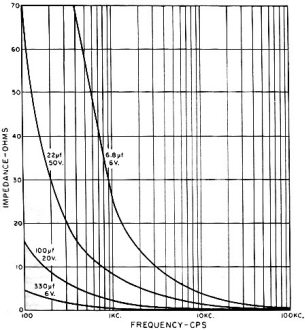

Fig. 7 - Impedance change vs. frequency measured at 25°C for

the same type of solid-electrolyte tantalum capacitor unit.

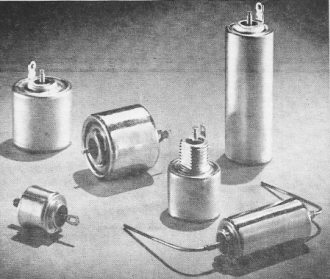

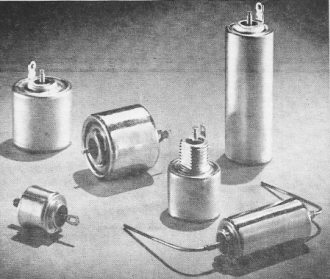

Grouping of special radiation-resistant tantalum electrolytics.

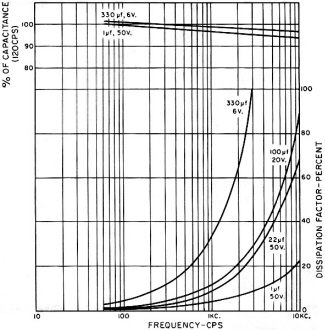

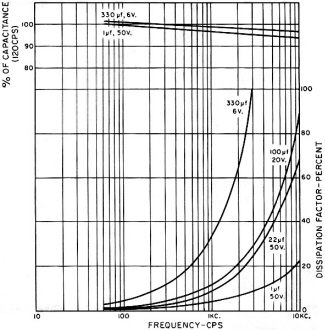

Fig. 8 - Typical capacitance and dissipation factor changes with

frequency at 25°C for same type of tantalum capacitor.

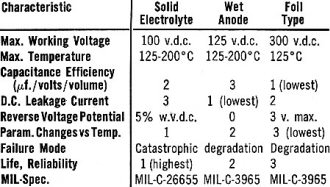

Table 2 - Ranking of some of the more important characteristics

of the three types of tantalum electrolytic capacitors.

Aluminum Electrolytics

Fig. 1 is a simplified representation of an aluminum electrolytic capacitor.

Both polarized and non-polarized types are shown. Normally a piece of aluminum foil

is etched to increase its surface area, then it is treated electro-chemically to

form aluminum oxide on its surface. The oxide is the dielectric of the capacitor

- the thickness of this oxide determines the voltage rating. Since this oxide film

is so thin and the surface area of the electrodes is so great, the capacitance produced

is very large.

Paper spacers are applied next to the aluminum oxide surface. These spacers prevent

direct shorts between anode and cathode foils. Thus, for higher voltages, more and

thicker spacers are used. The spacers also absorb the electrolyte, allowing it to

be retained in the correct place and providing intimate contact with the surfaces

of the anode and cathode foils as required for proper operation.

The cathode foil serves only as an electrical connection to the electrolyte.

The electrolyte is the true cathode and it has the ability to oxidize any imperfections

in the aluminum oxide dielectric.

Non-polarized capacitors use two anodes and have one-half the capacitance of

an equal-size polarized unit of the same voltage rating.

When electrolytic capacitors are used as energy-storage devices where the load

resistance is small compared to load inductance, current reversals may occur for

a short time. Accordingly, the voltage will reverse for the same time, making the

use of a non-polarized unit mandatory. Electrolytics for a.c. motor starting and

for audio cross-over networks should be non-polarized types. It is also wise to

consider using a non-polarized unit where large pulse signals are encountered. For

most applications, however, electrolytics are used across a d.c. voltage so that

the ordinary polarized units are employed. The designer must avoid voltage reversals

on polarized units.

Leakage Current and ESR

All electrolytic capacitors allow a small amount of d.c. leakage current to pass

through when rated polarized d.c. voltage is applied. This current will go up with

rising temperature and voltage. In general, the amount of leakage current is indicative

of the immediate quality of an electrolytic capacitor - the lower the better. Long

shelf life or storage will cause the leakage current to go up. Leakage can also

be detected by the time it takes to charge the unit to rated d.c. voltage.

ESR (equivalent series resistance) is a measure of the internal resistance of

a capacitor. This resistance is responsible for the heating effects associated with

a capacitor. The ESR of an electrolytic varies inversely with temperature. It is

also related to capacitance and frequency.

The dissipation factor (D.F.) of a capacitor is the ratio of the ESR to the capacitive

reactance. The power factor (P.F.) is the ratio of the ESR to the total impedance

of the capacitor. For low losses, power factor is equal to dissipation factor up

to 12%. Beyond this, dissipation factor increases without limit as losses go up.

Naturally, as the capacitor deteriorates, the ESR increases. If all these factors

are taken together, it can be concluded that ESR is a most important factor when

judging a capacitor for its use and end-life characteristics.

ESR also has an effect on the ripple-current rating of an electrolytic capacitor.

The a.c. ripple current combined with the ESR causes internal heating which must

be dissipated. A small additional loss caused by the d.c. leakage current is also

present, but is usually negligible.

A rule-of-thumb for determining maximum permissible ripple current conditions

is that the capacitor case temperature shall not exceed + 10°C above the maximum

rated temperature for the capacitor. It is also common to allow a 5°C increase

in case temperature rise for each 10°C decrease in ambient operating temperature.

Variations and Types

The capacitor designer can vary the cost, life, electrical parameters, temperature

range, and mechanical factors by changes in anode foil, cathode foil, paper spacers,

electrolytes, terminations, and packaging.

For example, using an anode with a high ratio of formation voltage to rated capacitor

voltage in combination with heavy paper separators and a conservatively activated

electrolyte (close to neutral ph), will result in a capacitor having long life,

-20 to +65°C temperature range, and medium changes in electrical parameters.

The choice of packaging can affect even this conservatively designed unit. Generally

the package can be judged by its ability to keep the electrolyte from escaping,

leaking, or diffusing from the container. The better the package is sealed, the

better the capacitor will retain its initial characteristics.

Capacitors are made and sold by intended end use in three grades: (1) commercial,

(2) industrial/instrument, and (3) premium. The commercial generally offers the

most capacitor for the lowest price. The industrial/instrument is a conservatively

designed capacitance section in the lowest priced package. The premium grade is

the finest capacitance section and best package for optimum electrical performance

in all respects.

Within each of these three categories, the manufacturer offers a very large variety

of sub-types that differ from each other in certain characteristics and applications.

Table 1 generalizes the importance of the various characteristics and ranks them

for the three main grades of capacitor. In addition, Figs. 2, 3, 4, and 5 show some

of the important characteristics of two specific types of aluminum electrolytics,

one in the industrial/instrumentation grade and one in the premium grade.

Tantalum Electrolytics

Tantalum is the second most popular oxidizable-base metal for use in electrolytics.

Tantalum oxide has almost twice the dielectric constant of aluminum oxide and is

exceptionally stable with temperature. It is also very inert to chemical attack

and this property allows the use of highly ionized acid electrolytes not possible

with aluminum. Tantalum is available in a high-purity form both as a foil and a

powder, thus more diverse physical arrangements are possible than with aluminum.

All these properties of tantalum make it possible to produce tantalum capacitors

with these advantages: higher μf./volt per unit volume, wider operating temperature

range, better temperature stability characteristics, longer life, more rugged construction

features, better electrical parameters, and excellent shelf life. The main drawbacks

are the greater cost and the lower operating voltages of the tantalum types.

Of all the plus features, the stable shelf life at temperatures of 30-40°C

for periods of time up to 5 and even 10 years without harmful parameter changes

is the most outstanding. This factor alone makes it possible to use electrolytics

widely in military gear. Thus, the expense of this rare metal was justified and

has led to the almost explosive development and use of several types of tantalum

electrolytics in the past ten years. In 1964, for example, 64,000,000 units, worth

$51,000,000, were sold.

Three major categories of tantalum electrolytics are being made and used in quantity.

They are the solid electrolyte types, foil types, and wet anode types with solids

outselling the other two by a ratio of 5 to 1 or more.

The tantalum foil types are similar in construction to the aluminum electrolytics.

The oxide on the anode foil is the dielectric, the electrolyte is the cathode, and

the cathode foil is primarily a connector. They are cased in aluminum with various

end seals made of rubber or Teflon. Generally, the package construction is more

critical because of the emphasis on long life and stable electrical parameters for

high reliability end use.

Wet-anode styles are made by pressing tantalum powder and a binder, in a mold

or die, to a given shape, usually cylindrical. These pellets are then sintered under

high vacuum and temperature to remove the binder and impurities, leaving a rugged,

porous metal pellet which is then electro-chemically treated to form a layer of

tantalum oxide. These anodes are then assembled in silver outer cases, filled with

an electrolyte, and sealed. Again, a rubber or Teflon end seal or a combination

of both are used to achieve a nearly hermetically sealed container.

Solid-electrolyte units are made by using a sintered anode which has an oxide

formed on it the same as that used for wet-anode types. The porous anode is then

impregnated with a liquid solution of manganous nitrate which is then fired in an

oven and converted to manganese dioxide. This semiconductor material is the solid

electrolyte and true cathode of the capacitor. A layer of carbon followed by a layer

of silver paint completes the cathode connection. This complete capacitor is then

soldered in a tinned metal container and a glass-to-metal seal affixed to the positive

end. Thus we have a rugged, hermetically sealed package with no liquids to leak

out.

A brief comparison of these three types of capacitors is given in Table 2. The

characteristics are ranked numerically for brevity and ease of interpretation.

A thorough and detailed description of all three styles, along with a quality-control

plan and much information on test techniques is available in the MIL-C Specs listed

in the table. These MIL-Specs are widely used as industry standards and many suppliers

are qualified to furnish products which meet these specifications. All major manufacturers

also have special designs and lines in addition to the Military types.

The graphs shown in Figs. 6, 7, and 8 illustrate typical characteristics of a

solid-electrolyte tantalum electrolytic capacitor.

Posted September 9, 2022

|