|

July 1965 Electronics World

Table of Contents

Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

A quick search for paper capacitors

turned up no manufacturers currently offering them. They were the capacitor of choice

for many decades until other types with superior dielectric material could be produced

at competitive prices. A special formulation of Kraft paper of various thicknesses

and chemical impregnations serves as the dielectric material between layers of conductive

foil. The vast majority of tubular type capacitors found in radios, televisions,

etc., prior to about 1960 were paper. One of the biggest disadvantages of paper

capacitors is vulnerability to drying out or absorbing moisture either through the

encapsulating material or via leaks in the case or around the external radial leads.

Most people who restore vintage electronics replace all paper capacitors out of

an abundance of caution, particularly because of the high voltages used by vacuum

tubes. Author William Robinson does a great job describing how paper capacitors

are manufactured, how they are used, and what their electrical characteristics are.

He tells the difference between a "wet" and a "dry" paper capacitor, which I've

probably known in the past, but had forgotten. This July 1965 issue of Electronics

World magazine presents similar articles on many types of capacitors.

Paper Capacitors

Fig. 1 - Capacitance change with temperature for kraft paper

dielectric material showing effects of various impregnants.

By William M. Robinson/ Chief Engineer, Cornell-Dubilier Electronics Div., Federal

Pacific Electric Co., New Bedford, Mass.

One of the most widely used types of capacitor, the paper type has characteristics

mostly dependent on the type of impregnant used.

Probably the least exotic member of the capacitor family is the paper-dielectric

capacitor. It is well known that mica types have much better over-all electrical

characteristics, film dielectrics have lower losses and better resistance to humidity,

and electrolytics and ceramics are smaller in size and lower in cost. Yet, after

seventy years of commercial application, paper capacitors are still the most widely

used capacitive component.

Paper capacitors range in physical size from the sub-miniature to huge complex

banks - in ratings from a few volts to hundreds of thousands of volts. Paper capacitors

are well suited for a.c. or d.c. service, pulse and energy-storage applications,

and for use in simple electronic devices or the most complex computers.

Basic Construction

Basic materials for all paper-capacitor elements are kraft paper, aluminum foil,

and a liquid wax or resin impregnant. The type of paper and impregnant, as well

as vital design factors, determine the rating and establish the over-all performance

characteristics of the finished capacitor. Packaging in a metal or insulated housing,

together with the type of terminals used, limits or extends the capacitor's capability

with respect to environmental performance.

Dielectric Structure

Fig. 2 - Insulation resistance characteristics of paper capacitors

showing effects of the various types of impregnants.

A paper capacitor receives its name from its basic dielectric material, kraft

paper. This material is not just a porous separator as found in electrolytic capacitors

but is a vital part of the dielectric structure.

Kraft capacitor tissue is manufactured from specially selected unbleached sulfate

pulp made from certain species of soft woods. These pulps are chosen for their uniformly

long fibers and high degree of purity. The pulps are made to rigid specifications

to insure that the fiber length, chemical composition, and purity of each lot will

meet exacting requirements.

There are many types and grades of kraft for use as a dielectric. Some of these

perform better on a.c., others on d.c., depending upon the dielectric strength and

dissipation factor.

Aluminum foil used for paper capacitors ranges from 0.00017 to 0.0005 inch in

thickness and has a purity of at least 99.8 %. The surfaces must be free from all

traces of rolling lubricants and other sources of contamination. Although tin-lead

alloy foil is occasionally used on very small capacitor elements, aluminum is preferred

because of its resistance to corrosion and electrochemical action, both of which

are apt to severely degrade the capacitor electrical characteristics under certain

operating conditions.

Use of impregnants for kraft paper improves the dielectric strength greatly and

increases the dielectric constant, consequently reducing both the size and cost

for any given capacitor rating. The impregnant also establishes the temperature-capacitance

characteristics as shown in Fig. 1 and is an important factor contributing to the

insulation resistance and dissipation factor of the finished capacitor. Some impregnants

are used exclusively in capacitors for d.c. service, others for a.c. capacitors,

depending upon the dissipation factor and dielectric strength they impart.

Design Factors

The voltage rating is established by the selection of the type, thickness, and

number of layers of kraft paper, together with the characteristics of the impregnant

used. Insulation spacing between metal parts of the element is directly related

to the voltage rating. Capacitance is proportional to the area of the aluminum-foil

electrodes and inversely proportional to the distance between the electrodes. Design

factors determining capacitance are C = (0.225 A K)/(T x 103) where A

is the active electrode area in square inches, K is the dielectric constant of material,

T is the dielectric thickness in mils, and C is the capacitance in microfarads.

Fig. 3 - How temperature affects life of a paper capacitor.

Winding of the capacitor element is accomplished with automatic or semi-automatic

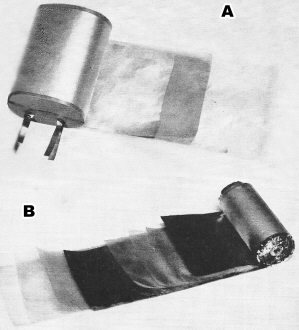

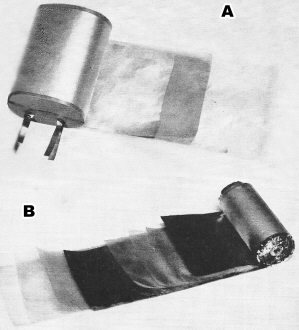

machines to minimize hand contact and to assure uniformity of the product. Fig.

4A shows a wound roll of kraft and aluminum foil together with inserted tinned-copper

contact strips. The extended-foil type of winding, shown in Fig. 4B, has the foil

protruding so connections may be made externally. Inserted-tab construction is generally

used for d.c. or low-frequency a.c. capacitors, the extended foil being used for

the smaller sizes, those used at higher frequencies, or where high-current pulses

or discharges are required in operation.

Paper capacitors are usually made with two aluminum foils separated by two or

more layers of kraft. Higher voltage windings often employ twelve or more papers

with as many as six foils.

Many of the smaller, lower-cost paper capacitors for the entertainment field

are impregnated at this stage. Assembly in non-metallic molded, tubular, or dipped

enclosures follows the operation of attaching lead wires. This is the wet-assembly

method of manufacture.

Most military and industrial capacitors, including all those for a.c. and higher

voltage ratings, are made by the dry-assembly process. This consists of assembling

the windings in metal containers and, after seaming, conducting the impregnation

process through a small hole in the case. The hole is then sealed.

Dry-assembly processed capacitors are made in almost an infinite variety of shapes

and sizes using squeezed-seam, rolled-seam, and welded-seam containers.

Terminal connections and insulators range from the sub-miniature to extremely

large sizes. The capacitor element and internal circuit connections are generally

heavily insulated from the case with thick sheets of kraft paper made to the same

requirements as for the dielectric paper.

Impregnation

Fig. 4 - (A) Paper capacitor element made with inserted contact

tabs. (B) Paper capacitor element extended foil construction.

Fig. 5 - How voltage affects the life of a paper capacitor.

Capacitors are loaded into the impregnation tanks where they are subjected to

extended heat and vacuum cycles to remove all traces of moisture and air. This process

is conducted at temperatures well below the critical level. which would be harmful

to the kraft paper, by extending the time and monitoring the temperature and vacuum

frequently. Force-drying the elements at excessively high temperatures to reduce

process time is generally detrimental to reliable operation.

After the internal parts of the capacitor element have been thoroughly evacuated

and dried, the tanks are flooded with the impregnant. Alternate vacuum and pressure

cycles are applied so that every fiber of the paper is thoroughly impregnated and

all voids are removed.

Finishing and QC

At the end of the impregnation cycle, the capacitors are removed from the tanks,

drained, sealed, and cleaned, and markings are applied over plain, painted, or plated

finishes. The QC (quality-control) program includes 100% tests of capacitance, dielectric

strength, seal, and mechanical inspection, as well as statistical checks of insulation

resistance and dissipation factor.

Test facilities are used to conduct life tests to determine quality-level and

service-life capabilities to verify design standards and to accumulate data for

reliability studies.

These facilities consist essentially of high-temperature ovens with adjustable

a.c. or d.c. power supplies and controls to maintain specified test conditions.

Before any new design standard or material is used in a paper capacitor, it is thoroughly

evaluated under accelerated life conditions .

Special Constructions

The capacitors previously described are of conventional foil-paper construction.

Other types are made using series-wound elements with high-voltage ratings and low-inductance

conductors for energy-storage and pulse applications. Such capacitors often are

required to deliver discharges of tens of thousands of amperes in intervals as short

as a few microseconds.

Plastic films are also used in conjunction with paper for a dielectric having

special characteristics of capacitance change with temperature and an extremely

high insulation resistance. The mixed dielectric combines the best properties of

both materials, frequently resulting in a more reliable product, although at a higher

cost.

Metallized paper capacitors with vapor-deposited metal electrodes are available

where space will not accommodate standard capacitors. The smaller size is obtained

by use of electrodes less than one micron thick and reduced di-electric for a given

rating. This type of unit has limited self-healing properties upon voltage breakdown,

as the electrode material will fuse and clear by electrical discharge. Metallized

capacitors are used in ratings up to 600 v.d.c. They should not be employed in circuits

where high insulation resistance is a necessary critical requirement.

Power Losses

Even though paper capacitors normally perform to more than 99.5% efficiency,

there are internal power losses that must be considered for units operating in a.c.

or pulse circuits. The methods of calculating power loss for a.c. operation is Watts

Loss = D.F. (E2/Xc) where D.P. is the dissipation factor of

the capacitor, E is the applied r.m.s. sine-wave voltage, and Xc is the

capacitive reactance of the device involved.

The method of calculating power loss for pulse operation is Watts Loss = D.F.

(C E12 N) where C is the capacitance in farads, E1

is the applied peak voltage, D.P. is the dissipation factor of the capacitor, and

N is pulses per second.

Approximately 0.06 watt per square inch of case surface area will result in a

10°C rise above the ambient temperature, assuming the capacitor is operating in

still air. This temperature rise has a marked effect on capacitor life, as will

be described.

When making the calculations for power loss, the dissipation factor may be assumed

to range from 0.0025 to 0.005, depending upon the type of impregnant used. The actual

temperature rise may, of course, be measured by testing the capacitor under the

given conditions.

Effects of Temperature

Paper dielectric capacitors are designed to operate at ambient temperatures of

55°C, 70°C, 85°C, or 125°C, depending upon the design standards

and impregnants used. Chlorinated or mineral waxes and oils are generally imited

to 85°C. Silicone-fluid, certain resins, and polyisobutylene-impregnated capacitors

may be used to 125°C. Higher temperatures result in gradual decomposition of

the cellulose fibers of the paper, as well as chemical changes In the impregnants,

causing degradation of electrical characteristics of paper capacitors.

Effects of temperature and capacitance are shown in Fig. 1. The large loss in

capacitance for some impregnants is due to change in the dielectric constant of

these materials. Such capacitors recover full capacitance when returned to room

temperature. Units operating in a.c. or pulse circuits frequently generate sufficient

heat through internal losses to recover full capacitance after less than one hour

of operation, even though they are exposed to very low ambient temperatures.

Fig. 6 - Attenuation characteristics of conventional and feedthrough

capacitors as measured in a 50-ohm circuit.

Designers must also consider insulation-resistance changes with temperature.

Shunt leakages are often 100 times greater at high ambient temperatures than at

25°C. as shown in Fig. 2. Insulation resistance of capacitors may also decrease

with life due to the effects of moisture on units made in non-metallic cases and

chemical changes in those made in hermetically sealed construction. Circuits should

be designed to accommodate ten times the leakage current specified for a given capacitor

with an additional adequate allowance for operation at high temperatures.

Dissipation-factor changes with temperature are not significant except for capacitors

operating in a.c. or pulse circuits.

Life performance of paper capacitors is related to ambient temperature. A lO°C

increase may reduce life as much as 50%, as shown in Fig. 3. Use of capacitors at

temperatures below maximum rating is recommended to extend life and lower failure

rates. This may also be accomplished by using capacitors at less than rated voltage

where higher ambient temperatures cannot be avoided. When designing a mechanical

layout for equipment, capacitors should be located as far as possible, or thermally

insulated rom, sources of damaging heat such as tubes, transformers, and power dissipating

resistors.

Capacitor Precautions

1. Keep all large capacitors, high-voltage or high-capacitance types, fully discharged

with a low-resistance or shorting wire connected across the terminals. Many persons

have been seriously injured by touching capacitors long after they had been removed

from a source of voltage.

2. Install capacitors away from sources of heat such as tubes, transformers,

or power resistors.

3. Do not exceed the temperature or voltage ratings unless such service is approved

by the manufacturer.

4. Do not discharge a capacitor with a direct short circuit unless the capacitor

is rated for this type of service. Direct discharge may result in an exceedingly

high current flow from the capacitor or set up an oscillatory discharge which may

be harmful to the capacitor. Limit the discharge current to one ampere unless the

capacitor is designed for higher current service.

5. Keep non-metallic cased capacitors in a dry storage area, not exposed to a

humid atmosphere .

6. Solder connections to capacitors in a manner which will not damage the seal.

On wire-lead types, soldering should be done at least 1/4" away from capacitor body.

7. Use a torque wrench when tightening nuts to avoid damage to capacitor seal.

8. Do not subject capacitors to any unusual environmental conditions of vibration,

shock, pressure, or immersion without first checking with the manufacturer.

9. Allow a maximum of ventilation for a.c. or pulse capacitors operating at high

ambient conditions.

Voltage Effects

A well-designed paper capacitor generally is rated for a life capability of more

than 50,000 hours. However, service conditions may shorten or extend this time.

In addition to the temperature effects, the applied voltage also has a considerable

bearing on the successful performance of a capacitor.

Both industry and the military have accepted in their specifications the use

of the fifth-power rule relating to the voltage life of paper capacitors for d.c.

operation. The following equation shows the relationship between the applied voltage

and operating life: L2 = L1(V1/V2)5

where L1 is the life at rated voltage V1, L2 is

the life at voltage V2, V1 is the rated voltage, and V2

is the intended operating voltage.

Fig. 5 shows that operation for 20% under rated voltage will result in almost

a 300% increase in capacitor life. This factor applies mainly to hermetically sealed

paper capacitors, but it may also be applied to non-metallic cased types if desired

circuit operation is not critical with respect to the capacitor insulation resistance.

Frequency Effects

Electrical characteristics of capacitance and dissipation factor remain fairly

stable at increased frequencies. There may be a 5% to 10% loss of capacitance at

frequencies above 1 mc. as compared with 60-cycle or 100-cycle values. Dissipation

factors will also be somewhat higher.

Since all capacitors contain some degree of series inductance as well as shunt

resistance, the effect of these on impedance must be considered in circuit design.

Inductance is caused by circuit connections to the capacitor element. Series resistance

is also contributed by these connections and the foil electrodes. Shunt resistance

results from normal dielectric leakage.

At the higher frequencies, conventional paper capacitors can be expected to perform

as shown in Fig. 6 with exact characteristics dependent upon capacitance value and

type of circuit connections to the element. Feedthrough capacitors of coaxial construction

have much better frequency characteristics although they employ paper dielectrics.

When using d.c. paper capacitors in audio- or radio-frequency circuits, precautions

must be observed to limit voltage to prevent overheating and greatly reduced life.

At 60 cycles, the maximum voltage applied should be less than 20% of rating; at

1000 cycles, 6%; and at 10,000 cycles and higher, only 1%. These values may be exceeded

only if a specific capacitor is evaluated under the intended conditions of operation

and is found to stabilize within its maximum ambient temperature rating.

Posted September 8, 2022

|