|

January 1963 Electronics World

Table

of Contents

Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

The basics of power transistor specification and selection have

not changed much since they became widely commercially available

in the 1960s. Although available package shapes, power handling,

cutoff frequencies, and other parameter options have been greatly

expanded, still the most important aspect is not just selecting

a power transistor but properly mounting it to ensure that the

rated heat dissipation capacity will be realized. This article

touches on some of those considerations and how to effectively

deal with them.

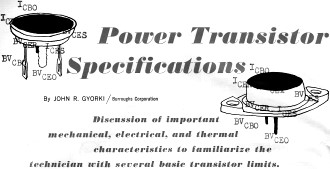

Power Transistor Specifications

By John R. Gyorki/ Burroughs Corporation

Discussion of important mechanical, electrical, and thermal

characteristics to familiarize the technician with several basic

transistor limits.

Although a great number of power transistor specifications

can be devised (and the number seems endless), a few of the

more common and important mechanical, electrical, and thermal

characteristics will be discussed. Without a doubt, the sophisticated

power transistor as we know it today would not exist if it were

not for the absolute control of a myriad of fine characteristics

during manufacturing and sorting. However, we are concerned

only with the ratings that decide how we can best keep a device

operating at its highest efficiency.

Mechanical Characteristics

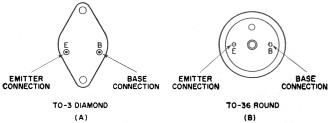

One of the industry's most common power transistor package

styles is the diamond base, also commonly known as the "TO-3."

It has straight pins that can be plugged into a suitable socket

(through a heat sink or radiator) and is usable with emitter

currents of ten amperes or less. Socket connections, however,

are not satisfactory connections and develop voltage drops;

just as voltage drops across a resistance. Also, excessive heating

losses occur when currents above the ten-ampere rating are used.

Therefore, we must utilize a more substantial type of transistor.

Another equally popular style is the round type, "TO-36."

It is generally used for emitter currents of 15 amperes and

above. Two straight pins are used for the base and emitter connections

with holes in them for soldering or they are available with

tinned leads welded directly to short emitter and base studs.

In both types, the collector is mechanically and electrically

fastened to the transistor case. The case serves as the collector

terminal and thermal radiator connection. This is done since

the collector junction becomes very warm during operation. The

emitter and base leads usually can be identified by observing

an "E" and a "B" stamped on the transistor case near the respective

leads. However, this is not always the situation, so a basing

diagram for the particular transistor being used should be consulted.

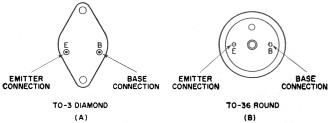

Fig. 1 shows the typical lead arrangement for both styles.

Fig. 1. Two common power transistor basing

arrangements. In both cases collector is internally connected

to case.

The diamond package is held in place by a 6-32 screw inserted

through each hole in the opposite corners of the heavy mounting

base. The round style is mounted by a single threaded stud projecting

outward from the bottom. A 10-32 nut and lock washer terminal

is used to secure it in place. The recommended torque on the

TO-36 mounting stud is 12 inch-pounds; no more should be used.

Appropriate insulating washers are often used at this time to

electrically insulate the transistor from the heat sink. This

will be discussed more fully under thermal conditions.

Transistors are not mechanically shockproof in themselves.

However, their rigid construction makes them suitable for

use in rugged type equipment. They are hermetically sealed with

a metal cap, either hot or cold welded to the mounting base.

This excludes moisture and light, both of which can degrade

the quality of the device.

Electrical Characteristics

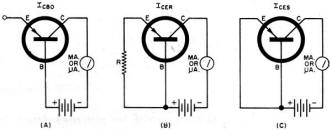

Leakage Current: Collector cut-off currents are simply other

words used for discussing inherent leakage currents associated

with the collector while the base and emitter are held to pre-determined

conditions.

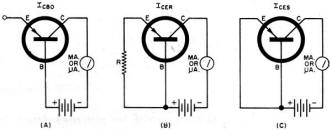

One of the most important collector leakage currents is ICBO

or more commonly, ICO. See Fig 2A. It is a leakage

current from collector to base with the emitter open-circuited

and is critical because it is most susceptible to temperature

variations. Since power transistors operate with high junction

temperatures, changes in ICO could greatly affect

the stability of the transistor and circuit. ICO

can easily be demonstrated by constructing the circuit of Fig.

2A. Heat from your hand or a lighted match brought near the

transistor will change the indicated leakage current enough

to be quite obvious.

Leakage current from collector to emitter with the base circuit

open is termed ICEO. This is a condition that could

be expected in switching applications; the base open and the

collector supply voltage present across the collector and emitter.

In better switching circuits, however, the base circuit is not

entirely open. It is usually reverse-biased or connected to

the emitter by a low value resistor.

Two other collector leakage currents are ICER,

with a specified resistor from base to emitter, and ICES,

with the base shorted to the emitter. They, as well as ICBO,

are measured with the conventional reverse-bias voltage from

collector to base. See Figs. 2B and 2C.

These leakage currents vary from a few microamperes to a few

milliamperes, depending on the specific transistor type. They

are among the most critical power transistor ratings and should

be kept as low as possible. Increased leakage current causes

a rise in junction temperature; a rise in temperature creates

more leakage current. This condition is called thermal runaway

and, if not controlled, could end in the destruction of the

transistor. Outside factors which generally determine the over-all

stability are controlled by the circuit designer.

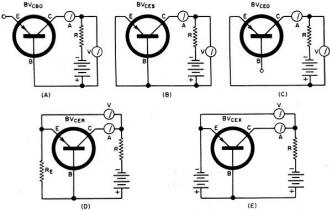

Voltage Breakdown: Collector breakdown voltage is that reverse

voltage applied between collector and emitter where the collector

current begins to avalanche and the collector current becomes

independent of collector voltage. This constitutes a group of

breakdown voltages where the base and emitter are held to various

constants. One such voltage is BVCBO, the reverse

breakdown voltage between collector and base with the emitter

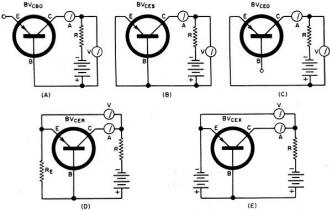

open. See Fig. 3A.

Two other breakdown voltages are BVCES, base shorted

to emitter, and BVCEO, the base open-circuited. Refer

to Figs. 3B and 3C. These are important considerations when

circuits with inductive loads are used. During transient voltage

peaks the actual instantaneous voltage present between collector

and emitter may be very much higher than the supply. It is at

this time especially we do not want the collector-to-emitter

voltage rating exceeded.

Another breakdown voltage is BVCER. This arrangement

has a specified resistor between base and emitter (usually around

10 ohms). See Fig. 3D.

BVCEX is the reverse breakdown voltage between

collector and emitter with a small reverse bias between the

base and emitter of 0.1 volt or more. This constitutes the absolute

maximum surge voltage limit that the transistor can tolerate.

Steady-state voltages are not used to measure these breakdown

voltages (as may be implied from the diagrams) because of the

excessive junction heating which could destroy the transistor

before final results were tabulated. Rather, a sweep method

is used, employing an oscilloscope and a sine-wave generator

where collector voltage versus collector current can be observed

and the breakdown curve clearly indicated without undue junction

heating. (See "Motorola Power Transistor Handbook," First Edition,

Chapter VIII "Transistor Testing," page 159.)

Collector saturation voltage, VCE (sat), is that

small voltage appearing between collector and emitter with such

large base drive applied (forward bias) that any further increase

in base current will not change the collector current appreciably.

In other words, this is where further collector injection (by

the base) brings to a halt the further increase of collector

current. Current gain is no longer considered existent at these

high current levels. Saturation voltage ratings of most transistors

are measured with a specified value of collector and base current.

Current Gain: Transistor current gain, beta,

is the ratio of a change in collector current to a change in

base current. This is the actual usable current amplification

rating of a particular transistor. Current gain specifications

in power transistors are generally given a range of values for

a specific transistor. These values are known as "large-signal

current gain" and are primarily used over the mean values of

maximum collector currents. "Small-signal current gains" are

sometimes specified for medium- and high-power transistors,

but more generally are considered a special case, since only

a very small portion of the allowable collector current is actually

used. That is, the current gain of a power transistor is much

higher at low collector current levels than at high collector

currents.

Cut-Off Frequency: Current gain frequency

cut-off, fae. (common emitter), is that frequency

where the small-signal current gain of the transistor is 3-db

down from some pre-determined value specified at a particular

frequency. This means that the current gain at fae

is 0.707 of the value specified at some reference frequency

(usually 1 kc.). The actual cut-off frequency is usually 10

kc. for most common power transistors.

Other Characteristics: There are a few other

normal operating characteristics concerning voltage and current

that are important and should be considered.

Fig. 2. Circuits for measuring leakage currents

of transistors.

Maximum emitter current is a common rating and means just

that; the maximum emitter current that can flow before permanently

damaging the device. This is probably one of the first practical

operating ratings considered for either replacement or new design

purposes.

Collector-to-emitter voltage is usually specified with the

base shorted to the emitter or with the base open-circuited.

In either case, the rating is specified with a certain value

of collector current.

Collector diode voltage, VCB (voltage, collector-to-base)

is indicated with a value of emitter-to-base voltage. The actual

circuit supply voltage should be less than the collector diode

or collector-to-emitter voltage ratings.

Fig. 3. The various breakdown-voltage measurements

are depicted.

Base current is usually given as a continuous value or a

maximum value. This base current rating should not be exceeded

or the junction will overheat and destroy the transistor.

Power and Thermal Ratings

Power dissipation and junction temperature rise are directly

related since the rise in junction temperature is caused by

power being dissipated in the junction. The maximum allowable

junction temperature of germanium power transistors is 100°C

(212°F). Any higher temperatures will soften and finally

melt the germanium. The average power dissipation is equal to

the emitter current multiplied by the collector-to-emitter voltage.

This will yield a hyperbolic curve that can be found on typical

output characteristics curves. The transistor circuit load line,

incidentally, must stay under this curve to insure reliable

operation of the transistor and keep excessive power dissipation

in the junction down to a safe level.

Thermal conductivity is the ability of a material to transmit

heat along or through itself. The heat conductivity path from

the transistor collector junction to the ambient air must have

as little heat resistance as possible. Since the junction of

an operating transistor heats and the temperature of the ambient

is normally less than the transistor junction temperature, it

is desirable to have the junction heat radiating into the surrounding

air and allow the junction to approach the temperature of the

ambient. If the heat transfer path from the transistor junction

to the air were 100% efficient, the junction temperature would

be the ambient temperature. However, this is not practically

possible. Between the transistor junction and the ambient air

we find the connection between the junction and the case, case

and insulator, insulator and heat sink, heat sink and air; all

of which total up to an opposition in the path from junction

to air. These obstacles are known separately as thermal resistance.

Each different thermal resistance has a unique coefficient number.

The coefficient of thermal resistance is expressed as a temperature

in degrees centigrade per watt of dissipation. Due to these

resistances, there will always appear a temperature differential

between transistor junction and ambient. This temperature differential

must be reduced to as low a value as possible.

The actual amount of temperature difference depends upon

the amount of power the transistor junction is dissipating.

We add up the individual thermal resistances, multiply the total

thermal resistance by the power being dissipated by the transistor

junction (P = EC x IC and add the results

to the ambient temperature. This gives us the transistor junction

temperature. If the junction temperature just calculated is

over the maximum allowable rating for the transistor, one or

more factors will have to be reconsidered. We can lower the

collector current and voltage to reduce power dissipation (and

consequently the stage output power) or, perhaps, we might lower

the ambient temperature. This could be done by adding a fan

for air circulation or by relocating the assembly in a cooler

environment. Any one of the thermal resistances may be lowered

to accomplish the same end, but this may be a little more difficult

to do. With the new values determined, the junction temperature

must be re-calculated. A useful formula for this is

TJ = PD (θJC + θCS

+ θSA) +TA where: TJ = junction

temperature in degrees C, PD = power dissipation

in watts (collector current x collector voltage), θJC

= transistor thermal resistance in degrees C/watt (junction

to case), θCS = insulator thermal resistance in degrees

C/watt (case to heat sink), θSA = heat sink thermal

resistance in degrees C/watt (heat sink to ambient), and TA

= ambient temperature in degrees centigrade.

Insulators used are mica, Teflon, or anodized aluminum. They

are used only where the collector must be electrically insulated

from the heat sink, but not thermally, Silicone grease applied

in small amounts between the transistor and heat sink (and insulator

when used) can reduce thermal resistance even more, enhancing

total heat dissipation. Teflon has the highest thermal resistance

with mica second and anodized aluminum the lowest. Teflon and

mica are not as mechanically durable as anodized aluminum,

but scratches through the anodized coat on both sides of the

aluminum can electrically short the transistor to the heat sink.

Silicone-coated mica insulators seem to be the most popular

choice at the present time in the industry at large. However,

no insulator at all, with silicone grease between the transistor

and heat sink, is the best possible situation.

The maximum amount of heat transfer takes place in the immediate

vicinity of the mounting studs on the TO-36 package and around

the holding screws on the TO-3 package. The mounting surface

is smooth and made of copper or is plated with another metal,

such as nickel, to enhance thermal conductivity. In general,

securing a heat radiator to the cap of the transistor affords

little or no heat dissipation. The transistor mounting base

surface is the only reliable area for connection to a heat sink.

Conclusion

The many power transistor specifications that are required

in the manufacture of transistors are not necessarily the same

specifications required for field technicians. Once the transistorized

equipment is designed and used, the technician need only be

aware of certain practical and general precautions in the replacement

of transistors, that is, if he does not have a direct replacement,

a substitute may be used. In such a case, a knowledge of a few

transistor characteristics will assist him in making an intelligent

guess as to a proper replacement and insure operation of equipment.

Posted July 30, 2015