|

April 1959 Popular Electronics

Table

of Contents Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

Probably when you think about

vacuum tubes, you envision the short type that plugged into your (or your parent's)

TV set or radio. While they were sophisticated in their own way and also required

careful assembly with a lot of manual operations, these high power tubes were in

a class of their own. Even the one in this article from the April 1959 Popular

Electronics magazine is not as complicated as some of the ones designed and

built for high power radar systems.

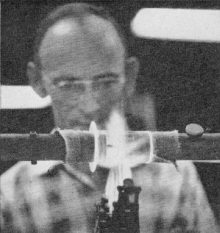

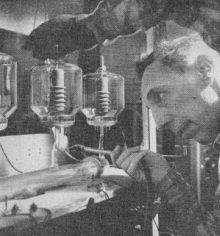

As always, it is interesting to note the lack of eye protection during assembly

operations, especially given that the glass could easily shatter at any point. I'm

guessing that the guy in Figure 1, doing the glass shaping operation over a

hot flame, only has on glasses because he happens to need them to see (i.e., they're

prescription).

Popular Electronics visits a tube manufacturer while... a Transmitting

Tube Is Born

Photos by Joe Petroveo Photos by Joe Petroveo

The manufacture of a high-power transmitting tube involves more than just assembling

a number of metal and glass parts. In order to meet the demands of industry, the

manufacturer must pay ever-increasing attention to reliability and long life. The

manufacturing processes which most affect tube life are those relating to the precision

with which the electrodes are manufactured and assembled, the extent to which all

impurities and foreign particles have been eliminated, and the degree of vacuum

obtained inside the tube.

Recently POPULAR ELECTRONICS visited the Amperex Electronics Corporation plant

in Hicksville, N. Y., to find out how a manufacturer of high-quality electron tubes

handles the problem of building long life and reliability into a modern high-power,

high-quality transmitting tube. A typical transmitting tube, the 5924A, was followed

through the different stages of its manufacture, and photographs of each of the

key steps were taken.

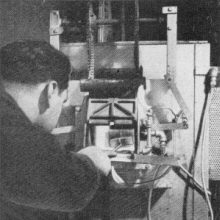

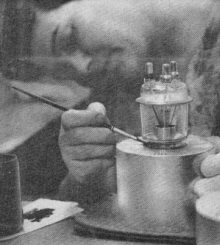

1 - Glass technology is an important aspect

of tube manufacturing. The glass is softened by jets of flame from a specially designed

fixture. When the glass is soft enough, the operator shapes it with special glass-shaping

tools. 1 - Glass technology is an important aspect

of tube manufacturing. The glass is softened by jets of flame from a specially designed

fixture. When the glass is soft enough, the operator shapes it with special glass-shaping

tools.

2 - Cleanliness is more than a byword to the tube manufacturer.

Tube life and reliability are decreased when impurities, such as oxides, are deep

within the metal elements. Here the electrodes are placed in a hydrogen atmosphere

furnace to "reduce" oxides.

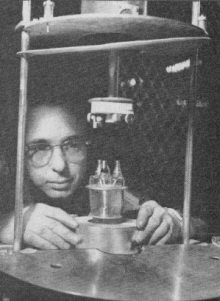

3 - The cleaning process goes

on. The most modern and efficient cleaning equipment is used by Amperex at various

stages of tube manufacture. Here an ultrasonic cleaner eliminates the last vestiges

of surface contamination which may exist on the tube's metal electrodes or glass

parts. 3 - The cleaning process goes

on. The most modern and efficient cleaning equipment is used by Amperex at various

stages of tube manufacture. Here an ultrasonic cleaner eliminates the last vestiges

of surface contamination which may exist on the tube's metal electrodes or glass

parts.

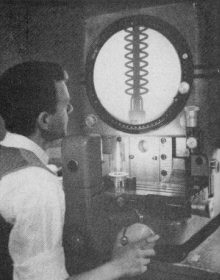

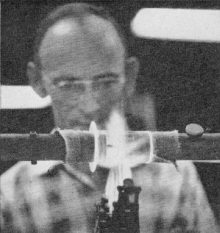

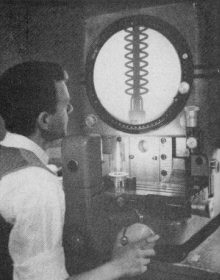

4 - The care exercised in fabricating and cleaning all the tube

components naturally extends to the inspection procedures. Parts are projected many

times their actual size on a screen so that even the slightest degree of misalignment

is easily detectable.

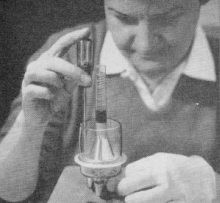

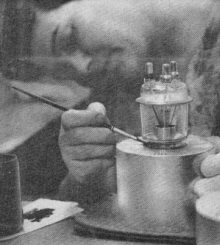

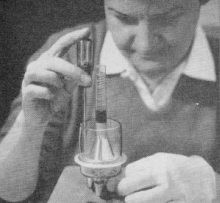

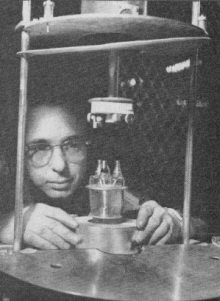

5 - Having insured the cleanliness and accuracy

of all components of the tube, the assembly procedure begins. The first step is

to assemble the delicate filament structure with hand tools. 5 - Having insured the cleanliness and accuracy

of all components of the tube, the assembly procedure begins. The first step is

to assemble the delicate filament structure with hand tools.

6 - The metal anode is now mounted. In background, note the different

stages of assembly of the 5924A tube. The assembler always keeps the working area

immaculately clean.

7 - Anode is sealed to the grid and cathode

mount. A highly skilled operator performs this exacting procedure on a lathe-like

machine which was designed for this operation. 7 - Anode is sealed to the grid and cathode

mount. A highly skilled operator performs this exacting procedure on a lathe-like

machine which was designed for this operation.

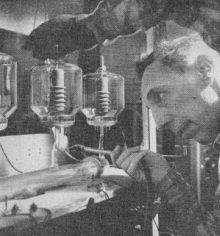

8 - Creating the vacuum inside a tube involves more than just

pumping out gas. It also includes removing gas trapped within the tube elements.

To do this. the electrodes are heated until the impurities are driven off. Here

the gas is pumped out (through the horseshoe-shaped glass tubing) while the tube

elements are heated.

9 - After all gases and impurities are pumped

out of the tube, it is necessary to make certain no other impurities enter. This

is done by "sealing off" the opening through which the gas was evacuated. A 5868

tube is shown here. 9 - After all gases and impurities are pumped

out of the tube, it is necessary to make certain no other impurities enter. This

is done by "sealing off" the opening through which the gas was evacuated. A 5868

tube is shown here.

10 - Now for the finishing touches. With the same care exercised

in the internal fabrication and assembly, all the external surfaces are carefully

silver plated and, at the same time, specific areas are painted for purposes of

identification of tube elements.

11 - The final step is to "fire it up" and

subject it to a thorough testing. All electrical characteristics are tested to insure

that the tube will not only meet, but exceed, specified ratings. 11 - The final step is to "fire it up" and

subject it to a thorough testing. All electrical characteristics are tested to insure

that the tube will not only meet, but exceed, specified ratings.

Posted October 18, 2021

(updated from original post on 10/7/2011)

|

Photos by Joe Petroveo

Photos by Joe Petroveo