July 1959 Popular Electronics

Table

of Contents Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

No, the electrolysis and

corrosion of boat propellers is not really in line with the theme of RF Cafe; however,

it presents the same sort of problems that grounding and anchoring systems for radio

antennas and equipment shacks have. If you bury a piece of metal in the Earth, it

will, over time, magically disappear. Much effort has been expended on the part

of both amateurs and professionals to mitigate the anodic action that occurs when

dissimilar conductors come into intimate contact because each metal - be it a base

or an alloy - has an electric potential relative to other metals. What happens when

there is a difference of potentials and a conduction path is present? Yep, current

flows. Through that action, material is physically transferred from the more positive

metal to the less positive metal. A relatively simple solution was discovered more

than a hundred years ago - a sacrificial element whose only purpose is to supply

the electrons, and hence material loss, in lieu of the important structure. It really

works. There was an article in the ARRL's

QST magazine

that did an excellent job covering this topic.

Note: I was able to exploit the electrolysis process for good to electroplate

some hardware on my 1941

Crosley 03CB console radio.

Electrolysis and Corrosion

How to save your boat from the ravages of electrical

corrosion How to save your boat from the ravages of electrical

corrosion

By Elbert Robberson

To a jet pilot, it's a flameout. To a parkway pilot, it's a flat tire in the

Holland Tunnel. For the owner of a boat, it's electrolysis - a boating problem ever

since metal parts have found their way aboard.

Talk to old-time boatmen, dealers, or shipyard mechanics, and you'll probably

hear plenty about this sea-water scourge ... stories of boat and engine parts falling

off, propellers turned to lace, boats sinking. It's true that these things can happen

because of electrolysis, but no conscientious boatman need suffer - because electrolysis

is easily prevented. First, however, let's find out exactly what it is.

What Is Electrolysis? The term "electrolysis" has come to be very loosely applied

in the small-boat field. What many boat-men call "electrolysis" is often really

some kind of corrosion.

Depending upon your dictionary, you will get all kinds of definitions from the

simple "The decomposition of a chemical by an electric current," to a fat paragraph

in Webster's New International Dictionary dealing with electrolytes, ions, and Faraday's

laws.

In the strict sense of the term, electrolysis concerns chemical changes in the

solution (in this case, the salt water) due to the passage of current. Since we

need a term to work with, however, let's call the corrosion of metal parts involved

in electrolysis "electrolysis corrosion."

When Does It Occur? Electrolysis corrosion occurs when direct current, as from

a battery or generator, passes through the water from one conductor to another.

You can get a good example of this activity very quickly and easily.

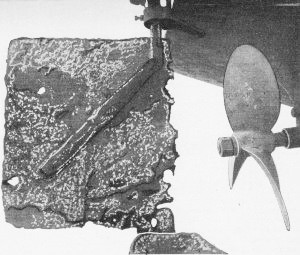

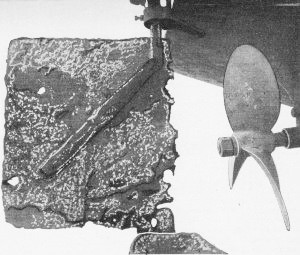

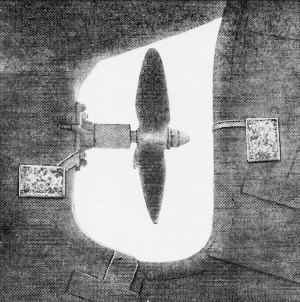

Severe galvanic corrosion in a steel rudder connected to copper-bottom

sheathing, bronze shaft and propeller. The boat almost became a casualty.

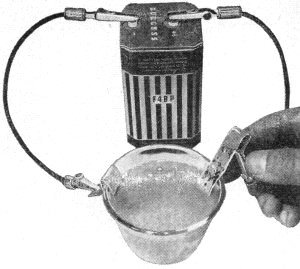

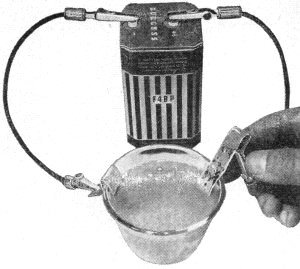

Electrolysis corrosion can be studied by immersing copper strips

in brine, and connecting a battery. In a short time, the current flow will cause

the positive electrode to corrode - eventually be entirely eaten.

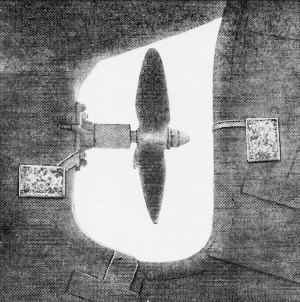

"Self-devouring" propeller at right suffered from faulty alloy,

so zinc block, mounted on wood, above, gave no protection.

Zinc blocks must be connected to metal that they are to protect.

This propeller nut has a zinc overcoat. Blocks on deadwood and rudder are connected

by copper straps to rudder post and stern bearing.

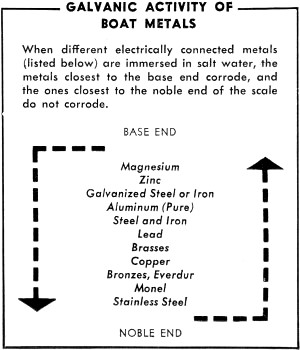

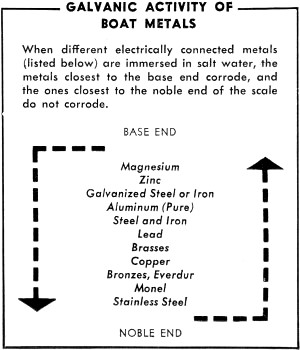

Galvanic Activity of Boat Metals

When different electrically connected metals (listed below) are

immersed in salt water, the metals closest to the base end corrode, and the ones

closest to the noble end of the scale do not corrode.

Dunk a pair of copper strips in a cup of salt water (table salt will do), and

connect them to a 6-volt battery. Bubbles boil from the negative electrode and nothing

much happens at the positive one - except that you may observe a green cloud creeping

out from it into the water. What is happening is that the metal of the positive

strip is going into the solution. In a short while, the weight loss of this electrode

can be measured with a sensitive scale. Carryon your experiment long enough and

there won't be any positive-end copper left.

This is what boatmen commonly call electrolysis - loss of metal due to battery

current between underwater parts. Run battery current between a boat's under-water

metal parts, and the positive part corrodes rapidly away. Stop the current flow,

and the process halts.

Since no one would reasonably connect a battery between underwater metals on

his boat, how can this possibly happen? Very easily, due to the fact that one side

of the battery circuit for motors and many electrical boat accessories and lights,

etc., is connected to the frame, shell, or "ground."

If you cross-ground one gadget by using opposite ground polarity from that used

on any other fixture, you've set up your boat for possible electrolysis corrosion.

The damaging current flow can take place through bilge water as well as through

the water under the boat; and it has also been known to take place through wet wood.

So, when installing fixtures, taking batteries ashore for charging, or doing anything

with the electrical system of the boat - keep the polarity of the ground connections

the same. Lately, manufacturers have begun to standardize to a large degree on negative

grounding; but don't count on it - investigate and be sure.

Another way to invite electrolysis corrosion is to use insufficient heavy wire

to supply power to heavy-drain items, such as a radiotelephone, which have ground

connections to the water. Voltage drop occurring in the ground leg of the power

supply circuit is just the same as with battery voltage: if there is a difference

of potential between points A and B under-water, no matter if the voltage is from

a generator, battery, or a voltage drop in a wire, trouble can result. Use large

wire for power leads to keep voltage drop close to zero. In addition, it is a good

idea to connect grounded objects together inside the boat with a "bonding" wire

of at least No. 10 gauge, and also bond in the engine frame and radio ground plate,

if any.

Galvanic Corrosion. Most underwater corrosion has no connection whatever with

electrolysis, contrary to popular thought. This trouble is simply "galvanic corrosion."

It takes place when three conditions are satisfied: the metals are in contact with

salt water; they are different in composition; and they are in electrical contact

through a metallic path: This forms a galvanic cell - like a primary battery cell.

Current is generated, flows through the water, and the metal supplying the current

corrodes.

This automatically happens when ordinary hardware-store brass is used for underwater

fittings or fastenings on a boat. Ordinary brass is an alloy composed of about 30%

zinc and 70% copper. The table below the galvanic activity of boat metals. Note

that zinc is at one end of the scale and copper near the other. Result: the zinc

is corroded, leaving a spongy copper mass in place of the brass. This has no strength,

so holes appear and fastenings disappear.

Many alloys are so cannibalistic that they will feed on themselves in this fashion.

So, the first rule which must be followed to avoid galvanic corrosion is to use

only fittings and fastenings which are made of seaworthy metal: bronze, Everdur,

Monel, stainless steel, and - if you are loaded - titanium, gold and platinum. All

are extremely resistant to corrosion.

Next, make sure that all of the different underwater metals are of the same family.

Avoid galvanized iron or steel if there is copper or any of the other more noble

metals around. Always try to use fastenings. which are more noble than the metal

of the object they are holding in place. This way, if there is the least bit of

corrosion, it will affect the comparatively bulky piece of hardware (which can afford

to lose a few grams weight) instead of the smaller fastening which may weaken to

the point of failure after the loss of just a little metal.

An outboard motor is, unfortunately, mostly active metal, and likely to corrode

quite rapidly if given the right conditions. To be on the safe side, when your motor

is not actually in use, keep it up out of the water ... especially if it has a bronze

propeller.

The importance of avoiding unlike combinations of metal underwater cannot be

stressed too much. And never install an object made of a metal about which you are

unsure.

The builders of a beautiful yacht, the "Sea Call," learned this the hard way.

Monel is practically proof against corrosion, so they built the underwater shell

of pure Monel. But the frames, stem and rudder were steel; and while most of the

rivets were Monel, a few steel rivets were accidentally mixed in. Shortly after

the vessel was placed in the water, one of these steel rivets disappeared, and people

began to get suspicious. Upon dry-docking the yacht, it was found that all of the

steel near the Monel metal was rapidly corroding, while the Monel, of course, remained

unaffected. The yacht was built in 1915 and scrapped in 1916!

Cures for Corrosion. Prevention is the best cure for corrosion, of course, but

many times it is not possible to have conditions as perfect as would be desired.

Good underwater metals may pick up dirt or oxide which changes their galvanic activity;

small impurities in a metal can create galvanic hot spots; and it is conceivable

that somewhat different metals must, of necessity, sometimes be used. On large ships,

you will often find combinations of aluminum and steel or bronze.

If it is necessary to use different metals, they must be electrically insulated

from each other. Plastic gaskets, Micarta separators and sleeves, rubber or other

water-proof insulating material can be used. As long as there is "no circuit," corrosion

will stay away.

You can also obtain protection with unbroken coverings of plastic paint, neoprene

compound, or other insulating coverings.

But the most popular method of protecting metals which unavoidably suffer from

galvanic corrosion was cooked up by Sir Humphrey Davy in 1824. The copper sheathing

on warships was corroding. "Attach blocks of zinc to the copper," said Sir Humphrey.

The idea was that, being more active than any surrounding metal, the zinc would

supply metal for all of the galvanic action, and the other metal would remain unscathed.

This idea was so good that even today U. S. Navy vessels which must be as light

and maneuverable as possible have tons of zinc anodes attached to their hull plating.

Special zinc anodes are made for small boats in the form of plates, propeller-nut

caps, and shaft sleeves, and are available from marine hardware stores. The zinc

must be as pure as possible (less than .0014% iron content), and it must be attached

or electrically connected to the metal which it is supposed to protect. It must

not be painted, however, and when it has corroded badly (it will corrode, if it

is providing any protection), the zinc anodes must be replaced.

A more modern method of protection is to supply a reverse current from a platinum

anode fitted to the hull, powered by a battery-operated regulated supply. Although

this is highly effective, it is somewhat more expensive.

The Scapegoat. Underwater metal comes apart for many more reasons than electrolysis

and corrosion. Among these are abrasion from mud and sand, and cavitation.

At the time when comparatively little was known about the installation of electrical

and electronic equipment on small boats it was fashionable, and very easy, to blame

every bit of underwater trouble on electrolysis. Radio had a bad name. Sober-faced

"experts" actually claimed that the instant you installed a radiotelephone on a

boat, the underwater hardware would start to fall off.

But since ghosts have gone out of vogue, don't tremble at the awful specter of

electrolysis. Keep track of your electrical circuits so that current does not flow

through the water; use sea-going metals and be sure they are properly mated; and

use zinc anodes, if necessary. Take these basic protective measures, and you should

have no trouble.

Posted July 16, 2019

(updated from original post on 10/26/2011)

|

How to save your boat from the ravages of electrical

corrosion

How to save your boat from the ravages of electrical

corrosion