|

April 1959 Popular Electronics

Table

of Contents Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

Power transformers have not

changed too much since this article was appeared in a 1959 issue of Popular

Electronics magazine. Efficiencies might be up a bit, and maybe sizes down,

but other than that, the equations and implementation methods are about the same.

True, you will not find a lot of new transformers with secondaries that sport vacuum

tube filament and plate voltages, but their equivalents for ±15, ±12, ±5, etc. are

out there. 60- Hz transformers are of course most common here in the U.S. (50 Hz

in Europe), and 400 Hz is a common frequency for military equipment (ships,

aircraft, tanks, etc.), but I was surprised to learn that 25-cycle (25 Hz)

power was at one time common near hydroelectric plants. Niagara Falls, in Buffalo,

New York, was one of the first to adopt 25 Hz, in part because of a belief

that the AC motors used in nearby industrial applications would be more reliable

at lower commutator frequencies. Here is an informative paper from IEEE entitled, "25-Hz at Niagara

Falls - end of an era on the Niagara Frontier." Other frequencies such as 8-1/3

Hz, 16-2/3 Hz, 25 Hz, 33-1/3 Hz, and 41-2/3 Hz were proposed. As you might expect,

a lot of politics and corporate battling played into the final decision.

How to Make Power Transformer Substitutions

By Eugene Richardson By Eugene Richardson

Power Transformers - those bulky heavy, and expensive items - are found in all

types of electronic equipment. Whatever your interest in electronics, you're sure

to have noticed one or more of these steel-clad components quietly humming to itself

off in a corner of the chassis. When a replacement is needed, or you're searching

for a particular item for a construction project, it's necessary to know the inside

story of the power transformers; how interchangeable are the units and what do the

specs mean?

The purpose of a power transformer is simply to convert the a.c. line voltage

into the higher and lower voltages required by electronic circuits. The two types

you'll come across are known as high-voltage plate and filament transformers. In

receivers and amplifiers you'll find the functions of both combined in a single

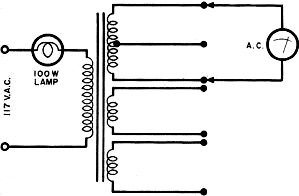

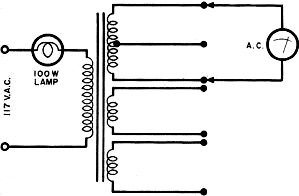

multiwinding general-purpose unit. A typical power sup-ply is in Fig. 1.

Size and Frequency. Physical size of a power transformer depends

upon both its power handling capacity and operating frequency. The higher the unit's

power rating, the larger the diameter of the wire needed in its windings and the

greater the amount of iron laminations in its core. A transformer designed to power

a one-tube audio preamplifier may measure a little over an inch on each side and

may weigh but a few ounces. However, the power transformer of a moderately large

television receiver will measure several inches on each side and be quite heavy.

The lower the frequency, the more iron is needed in the transformer core to maintain

operating efficiency. Hence, transformers designed for 25-cycle line operation are

larger and heavier than the more familiar 50-60 cps units. Since higher frequency

transformers require less iron, military equipment transformer frequencies may range

from 400 to 1000 cps.

Fig. 1 - Schematic wiring diagram of a typical power supply.

Fig. 2 - Standard color coding for power transformer leads.

Unless you live in an area supplied with 25-cycle power (a common frequency of

hydroelectric power plants), the chances are you use 60-cycle transformers in all

your projects. However, 400-cycle (or other high frequency) transformers are encountered

on the surplus market. As a general rule, a transformer will overheat, and may burn

out, if used at frequencies appreciably lower than those for which it was designed.

Thus, a 60-cycle transformer may overheat if connected to a 25-cycle line, as will

a 400-cycle transformer connected to a 60-cycle source.

Specifications. Aside from operating frequency, a power transformer's

electrical specifications are given in terms of primary voltage, secondary voltages

and rated currents. In some cases, the unit's power-handling capacity may be indicated

in watts or volt-amperes (va = primary voltage multiplied by current in amperes).

A typical filament transformer may have the

following specifications: Primary, 105 - 120 volts, 60 cycles; Secondary, 6.3 volts,

CT, 2 amps. Such a transformer is designed for operation on a standard 60-cycle

power line. Although line voltage is nominally 115 volts, it may vary from 105 to

120 volts, depending on local conditions. A typical filament transformer may have the

following specifications: Primary, 105 - 120 volts, 60 cycles; Secondary, 6.3 volts,

CT, 2 amps. Such a transformer is designed for operation on a standard 60-cycle

power line. Although line voltage is nominally 115 volts, it may vary from 105 to

120 volts, depending on local conditions.

This unit's center-tapped (CT) secondary winding has a nominal rating of 6.3

volts, and is capable of delivering a current of 2 amperes without overload. The

exact secondary voltage will vary with the applied primary winding voltage and the

secondary load. If overloaded, the transformer will supply more than 2 amperes,

but the voltage will be low and the unit may overheat. Conversely, if less than

2 amperes are drawn, the secondary voltage may be somewhat higher than 6.3 volts.

Frequently, the presence of a center tap is indicated in the secondary voltage

specification rather than the abbreviation of "CT". For example, a transformer might

carry the following specs: Primary, 105-120 volts, 60 cycles; Secondary, 350-0-350

volts, 50 ma. This transformer has a standard primary winding and a secondary winding

delivering 350 volts on each side of its center tap; rated secondary current is

50 milliamperes. The secondary winding could also be described as 700 volts-CT,

50 ma.

Where a multi-winding power trans-former is used, such as in Fig. 1, the

voltage and current rating of each secondary winding are listed separately. A typical

set of specs reads as follows: Primary, 105-120 volts, 60 cycles; Secondary No.1,

300-0-300 volts, 50 ma.; Secondary No.2, 5.0 volts, 2 amps; Secondary No.3, 6.3

volts, CT, 3 amps.

Lead Identification. Connections to transformers are made to

fixed terminal lugs or to wire leads. If you purchase a new transformer, you'll

find that lead connection instructions are printed on the box, on a label on the

transformer, or on a separate sheet. But if you have a transformer salvaged from

another project or taken from a piece of used equipment, these connections probably

will have to be determined anew.

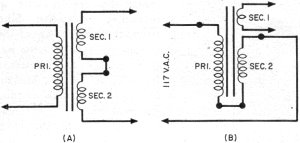

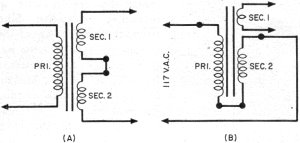

Fig. 3 - Basic test which you can make to identify power

transformer windings using an a.c. voltmeter.

Fig. 4 - Two tricks to use in making emergency substitutions:

(A) two filament windings can be connected in series to supply higher voltages;

(B) a filament winding can be connected in series with the primary to lower all

secondary voltages.

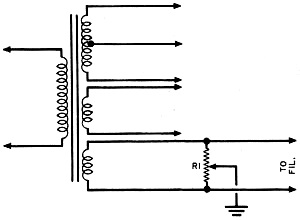

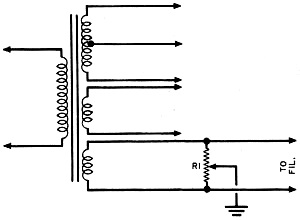

Fig. 5. How to obtain an "artificial" center tap on a filament

winding.

If the unit is of recent manufacture, and equipped with color-coded leads, you

can identify the leads by referring to the standard power transformer color code

given in Fig. 2. Filament center taps are not included in all transformers.

If the transformer is not equipped with color-coded leads, a simple technique

will indicate which is which. With the transformer disconnected, use an ohmmeter

to determine pairs of leads and center-tap connections. Check the resistance of

each winding. The winding having the highest resistance is usually the high-voltage

secondary and may read from 25 to several hundred ohms. The winding having a medium

resistance - generally from 5 to 25 ohms - is the primary. Finally, the lowest resistance

windings, usually less than I ohm, are the filament windings.

Having made a tentative identification, connect a standard 100-watt lamp in series

with the leads chosen as the primary leads and a source of line voltage as in Fig. 3.

The lamp should light, but not at normal brilliance. If it lights to normal brightness,

either the transformer is shorted (and should be discarded) or you've made an error

in choosing the primary leads.

Next, using an a.c. voltmeter, check the voltage across each winding, including

the primary. The ratios of these voltages will help you to identify the windings.

As a final step, remove the series lamp, applying full line voltage to the transformer

primary. Use your a.c. voltmeter to check the unit's output voltages and to identify

each winding positively. Remember that the voltage will read slightly higher than

normal because of the absence of a load.

Making Substitutions. A substitute power transformer should

be used only if the specified component is unobtainable.

When choosing a substitute, make sure that its secondary voltage specifications

are the same and that its current ratings equal or exceed those of the original.

For example, a transformer with a 250-0-250 volt, 60-ma. secondary may be used

as a satisfactory replacement for a unit rated at 250-0-250 volts, 40 ma. Similarly,

a filament transformer rated at 6.3 volts, 3 amperes, is a satisfactory substitute,

electrically, for a unit rated at 6.3 volts, 1.5 amperes.

A 5% difference in secondary voltage ratings will usually not affect circuit

operation. Thus, if a project calls for a transformer rated at, say, 360-0-360 volts,

substitutes with ratings of either 375-0-375 or 350-0-350 generally will be satisfactory.

Where a special transformer having several secondary windings is required, and

an exact duplicate is unobtainable, separate transformers can be used in place of

the single multi-winding unit, provided that adequate mounting space is available.

The transformer's 117-volt primary windings are connected in parallel.

If special filament or bias voltages are required,

two (or more) windings can be connected in series to supply the necessary voltages,

as shown in Fig. 4(A). Connect adjacent winding leads together temporarily

and check the output voltage obtained between the "free" leads, using your a.c.

Voltmeter. If the output voltage is less than expected, the windings may be "bucking."

In this case, interchange the connections to one winding. If special filament or bias voltages are required,

two (or more) windings can be connected in series to supply the necessary voltages,

as shown in Fig. 4(A). Connect adjacent winding leads together temporarily

and check the output voltage obtained between the "free" leads, using your a.c.

Voltmeter. If the output voltage is less than expected, the windings may be "bucking."

In this case, interchange the connections to one winding.

It may be necessary to reduce the circuit's B+ voltage after installing a substitute

transformer. There are several ways of doing this. A small resistor (5 to 25 ohms,

10 watts) can be connected in series with one of the primary leads, or the effective

turns ratio of the transformers can be reduced by connecting one of the filament

windings in series with the primary, as shown in Fig. 4(B). The preferred methods

would be to substitute a rectifier tube with a larger internal voltage drop or lower

the value of the input filter capacitor (C1 in Fig. 1). If the hum level in

the d.c. output goes up; raise C2's value.

Often, a center-tapped filament winding may be needed, but may not be available

on the substitute transformer. In such a case, an electrical "center-tap" can be

obtained by connecting a 50-to-100-ohm adjustable wire-wound resistor across the

filament winding, as shown in Fig. 5. The adjustable tap is centered on the

resistor.

It is not necessary to use all the windings available on a multi-winding power

transformer. For example, suppose you need a general-purpose power transformer,

and find one with secondary specifications which match those of the needed unit

but with an "extra" 6.3-volt filament winding. Simply ignore the extra winding,

taping its leads to one side (taking care that they do not short together).

Mechanical specifications are important only when the substitute unit is used

as a servicing replacement or in the construction of equipment where the component's

physical size and shape are important. These specifications include overall dimensions,

weight, and type of construction or mounting.

Posted November 9, 2022

(updated from original

post on 10/14/2011)

|

By Eugene Richardson

By Eugene Richardson

A typical filament transformer may have the

following specifications: Primary, 105 - 120 volts, 60 cycles; Secondary, 6.3 volts,

CT, 2 amps. Such a transformer is designed for operation on a standard 60-cycle

power line. Although line voltage is nominally 115 volts, it may vary from 105 to

120 volts, depending on local conditions.

A typical filament transformer may have the

following specifications: Primary, 105 - 120 volts, 60 cycles; Secondary, 6.3 volts,

CT, 2 amps. Such a transformer is designed for operation on a standard 60-cycle

power line. Although line voltage is nominally 115 volts, it may vary from 105 to

120 volts, depending on local conditions.

If special filament or bias voltages are required,

two (or more) windings can be connected in series to supply the necessary voltages,

as shown in Fig. 4(A). Connect adjacent winding leads together temporarily

and check the output voltage obtained between the "free" leads, using your a.c.

Voltmeter. If the output voltage is less than expected, the windings may be "bucking."

In this case, interchange the connections to one winding.

If special filament or bias voltages are required,

two (or more) windings can be connected in series to supply the necessary voltages,

as shown in Fig. 4(A). Connect adjacent winding leads together temporarily

and check the output voltage obtained between the "free" leads, using your a.c.

Voltmeter. If the output voltage is less than expected, the windings may be "bucking."

In this case, interchange the connections to one winding.