|

December 1961 Popular Electronics

Table of Contents Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

Ultrasonics as a

cleaning method was a big thing in industry long before this article appeared in

a 1961 issue of Popular Electronics magazine, but as with microwaves

(for other than broadcasting), ultrasonics was beginning to move into domestic,

medical, and small business applications. If you are not familiar with the

capabilities of ultrasonics, Ken Gilmore will enlighten you on methods for

cleaning air, measuring fat content in tissue, cleaning extremely small

mechanical components, meat tenderizing, ship hull barnacle prevention, and

other such things. My first exposure to ultrasonic cleaning was while at

Westinghouse Oceanic Division in Annapolis, Maryland, where we had an ultrasonic

vat (~5 gallon) filled with

methyl chloroform (1,1,1, trichloroethane) for degreasing and defluxing electronics assemblies. We

got it in 55-gallon drums. The methyl chloroform was heated to enhance its

cleaning action, and there was a pipe surrounding the perimeter of the open top

that had cold water running through it which caused the evaporated solution to

condense and drain back into the vat. Back in the day, we were still using

60Pn/40Sn solder with a rosin core, so MIL-SPEC procedure required a thorough

cleaning to prevent corrosion. After dunking a soldered PCB or connector in the

vat for a couple minutes, the solder joints would shine like a jewel. It was

miraculous. BTW, we also used MEK (methyl ethyl ketone) quite frequently for

stubborn contamination that was preventing the solder to wet surfaces

sufficiently. Isopropyl alcohol was the main cleaner used during assembly. No

masks, no gloves, no safety glasses, yet in four years I don't recall a single

incident.

Ultrasonics -Successes of Silent Sound

By

Ken Gilmore By

Ken Gilmore

Last May 16th, President Kennedy strained his back while planting a tree in Ottawa,

and was again victim of the effects of an old back injury. To relieve the pain and

promote healing, his doctors prescribed doses of "ultra-sound."

That same day, a housewife in Fresno, Calif., dipped her dinner dishes into an

ordinary-looking sink full of clear water, pulled them out after a few seconds,

and put them in a rack to dry. In spite of her apparently sloppy housekeeping, the

dishes came out antiseptically clean.

That night, millions of Americans all over the country were pressing buttons

on cigarette-case-sized remote control units and watching their TV sets across the

room change channels and turn themselves on and off.

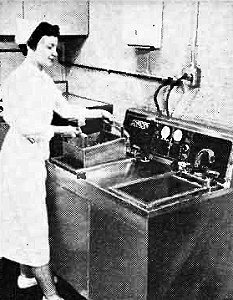

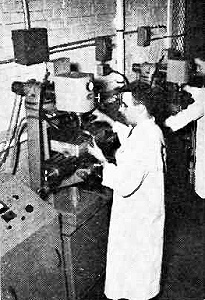

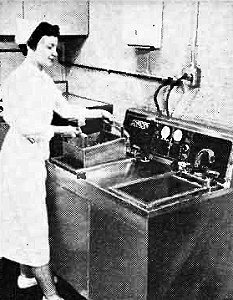

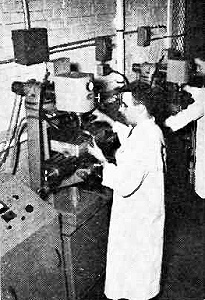

One of the most popular applications of ultrasonic energy is

cleaning. Above, a hospital worker cleans surgical instruments by dipping them in

an ultrasonic bath. Instruments are cleaned better, faster, than with hand-scrubbing

method. Branson Instruments

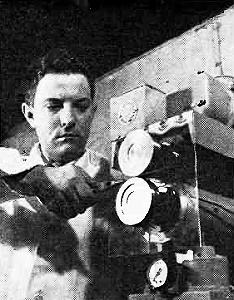

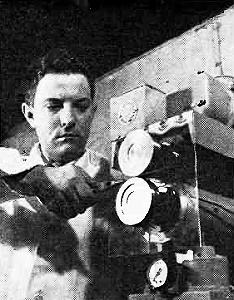

Another use of ultrasound is checking fat content of beef on

the hoof, as is being done at Colorado State University. Colorado State University

Even dried egg yokes can be "brushed" from your most prized china

with ultrasound. Prototype dishwashers, such as this Westinghouse unit, have proven

successful in consumer tests across the country, but they are still too expensive

for the average home. Westinghouse

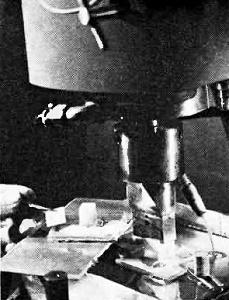

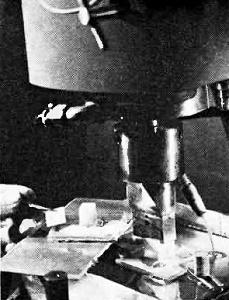

Industrial applications of ultra-sound are many a varied. The

Raytheon Company, for example, employs the ultrasonic impact grinder below to slice

blocks of quartz into thin sheets for use as crystals in receivers. Raytheon

Ultrasonic welding machine pulls strips of metal between vibrating

rollers which literally pound the strips into a single sheet. Process generates

no heat and is suitable for such hard-to-weld metals as aluminum foil, which would

be damaged by temperatures of more conventional welders. Westinghouse

Intricate designs can be reproduced in glass or ceramic with

ultra-sound. A counterpart of the design appears on an oscillating tool or die,

which drives liquid abrasive into the work-piece to cut the material. Raytheon

These seemingly unrelated incidents are linked by a common bond: they all had

something to do with ultrasonics - sound above the range of human hearing. And newly

discovered ultrasonic tools and techniques are now revolutionizing hundreds of industries.

For example:

• Brewers "pump" ultrasonic sound through bottles of beer before putting

on the caps. The ultra-sound makes the brew foam violently, releases all trapped

air, and renders the beer immune to oxidation and spoilage during storage.

• Warehousemen have found that even low levels of ultrasonic sound drive

rats crazy. After being subjected to such treatment for a day or so, the rodents

give up and move away - permanently.

• Space workers now perform thickness measurements on missile nose cones

- which must be machined to exact tolerances to withstand the heat of re-entry -

quickly and easily with radar - like ultrasonic gadgets. The thickness, accurate

to thousandths of an inch, is read directly on a television-like tube.

• Railroad men check rails, car wheels, and other massive steel parts with

a similar radar-like detector which spots flaws and cracks far better and faster

than older methods.

Why Silent Sound?

Ultrasonic waves are useful largely because

we can pack tremendous power into them. Sound we can hear could do many of the same

jobs, but it would split eardrums for miles around. We don't often think of sound

as having physical power, but it has. When we drive units with the tremendous energy

levels used in ultrasonics, the results can be spectacular.

Take ultrasonic cleaning, for example. Dip anything dirty into a tank of water

being agitated by ultrasonic waves, and the sound energy literally tears the dirt

off. This tremendous cleaning power comes from a phenomenon scientists call cavitation.

As the powerful ultrasonic waves vibrate through a liquid, millions of microscopic

bubbles continuously form and collapse with such terrific force that they create

pressures up to 20,000 pounds per square inch. The ferocious scrubbing action of

the collapsing bubbles blasts the dirt off the surface to be cleaned.

Today, hardly a manufacturing industry exists that doesn't use some type of ultrasonic

cleaning. In one factory, a dirt- and grease-coated gas turbine rotor is dipped

into an ultrasonic bath, to be pulled out a few seconds later shining and clean.

In other plants across the country, all kinds of parts - printed-circuit boards,

electric shaver heads, and thousands of other items - come out of their ultrasonic

baths with every tiny crevice literally sparkling.

Hospitals throughout the nation now use ultrasonic cleaners to scrub surgical

instruments. Dr. George W. Dana, director of the North Shore Hospital in Manhasset,

Long Island, was amazed when he used an ultrasonic unit for the first time. "It

even took off stains we thought were a permanent part of the finish of surgical

instruments," he said.

The energetic bubbles are so small that they can sneak into tiny holes and crevices

impossible to clean by other methods. Scouring the tiny, hair-like tube through a

hypodermic needle, for example, is a snap.

From Hours to Minutes

Before the advancement of ultrasonic techniques, one large manufacturer of camera

lenses kept a staff of 24 women busy around the clock cleaning lenses. The delicate

glass discs are coated with a sticky pitch to hold them steady during the grinding

process, and getting the pitch off was a nasty job. Now, the company dumps the whole

batch into an ultrasonic cleaner and scours an entire day's output in jig time.

Likewise, delicate jet engine nozzles used to be discarded when they began to

show signs of clogging, since there was no practical way to clean them reliably.

Today, with ultrasonics, they're as good as new in minutes.

Some watchmakers now offer a while-you-wait cleaning service for your watch.

They flip the back off your timepiece, dip it in an ultrasonic tank, dry it with

a blast of hot air, put in a few drops of oil, then return it to you. The process

is both fast and cheap.

A cash register maker now cleans assemblies of 5000 complex parts in 7 1/2 minutes

without dismantling a single part; previously it took a skilled man days to do the

job. Auto servicemen are installing ultrasonic cleaners, too; your carburetor, among

other complex assemblies, can be cleaned in seconds without being dismantled.

From Egg Yokes to Soup Cans

Within a few years you may be able to buy a dishwasher that blasts even dried

egg yoke off your most fragile china without damaging it. Various companies have

been promising this one for several years now, and test models operate beautifully.

Some makers are also predicting ultrasonic washing machines for your clothes, but

this is still further in the future. The holdup: nobody has been able to get the

units down to a moderate price.

Even air can be cleaned ultrasonically. Aim a beam of silent sound through dirty

air and the vibrating waves jam tiny floating particles together, causing them to

accumulate in clumps and drop out. This technique has already been incorporated

in many industrial smoke precipitators, and recent experiments at Orly Field near

Paris, France, indicate that it can also be used to disperse fog. The trouble to

date is that enormous amounts of power are needed to cover a large area - an airport

such as Orly Field, for example.

Crewmen aboard atomic subs are warned of hull leaks by ultrasonic liquid detectors.

A tiny ultrasonic probe vibrates freely in open air. But when you cover its tip

with water, the vibration stops, and an alarm goes off. The same detector will keep

ground crews alerted to the fuel level in the tanks when America's giant rocket,

the "Saturn," blasts off for outer space. Meanwhile, back on planet Earth, one soup

manufacturer has tested the same indicator as a foolproof method for determining

when soup cans are full.

Meat and Milk, Too

The Reflectone Corporation of Stamford, Conn., has perfected a method of tenderizing

meat with ultrasonics. The powerful waves pound tough cuts of meat into tender steaks

without producing the flabbiness chemical tenderizers sometimes do. Silent sound

helps produce better steaks in another way, too. Researchers at Colorado State University

rigged a gadget to shoot low-powered ultrasonic waves painlessly into beef on the

hoof - the returning echoes tell how much fat and how much "meat" is on the critter.

Ultrasonics will soon produce a better cup of coffee. Treat green coffee to a

dose of ultrasonics before roasting, and the silent sound blasts a series of microscopic

holes through the beans. During roasting, heat penetrates more evenly, driving out

oils that can cause rancidity.

Some dairies are now using ultrasonic homogenizers. As an added advantage, the

ultrasonic waves go to work on bacteria, killing most of them. Experimenters think

it may soon be possible to forego pasteurizing altogether and count on just a single

blast of ultra-sound to homogenize and pasteurize milk simultaneously. One company

recently patented an ultrasonic gadget which sends a signal zooming through a tank

of milk, checks the returning echo, and comes up with an automatic analysis of its

nutritional value.

Welding and Drilling. A new machine by Westinghouse actually

welds metals by ultrasonic energy. Two pieces of metal are run between a couple

of rollers vibrating at ultrasonic speed. The intense vibration breaks down the

surface molecules of the individual pieces where they come together and causes them

to interlock.

Nobody but a comedian would have suggested drilling square holes a few years

ago. But ultrasonic drills can now drill them square, star-shaped, in the form of

a cuckoo bird, or what have you. A shaft driven up and down thousands of times a

second, but with a movement so slight you can't even feel it, does the job.

The "drilling" is accomplished by flowing a slurry of abrasives between the shaft

and the material to be drilled. The shaft comes down, strikes the abrasive particles,

and causes them to dig into the material like a flock of frantic woodpeckers. In

no time at all, a hole the exact shape of the drilling shaft is punched through.

Unlike other methods, the drill doesn't even have to be as hard as the material

it is drilling. Naturally, this leads to spectacular tricks. With an ultrasonic

setup, you can drive a fountain pen through a pane of glass or slice off a piece

of extra-hard steel with a cheap pen knife.

Wartime Development. Ultrasonics, now going to work in literally

hundreds of ways, has been known for years. Perhaps the first practical application

was the so-called "silent" dog whistle. Dogs can hear it but people can't.

Men first put ultrasonics to work - past the "dog whistle" stage, that is - in

World War I when a French scientist named Paul Langevin built a sonar machine for

detecting submarines. The war was over before Langevin refined his invention enough

for practical use, but when World War II came along, sonar was further developed.

And after the war, the strange properties of ultrasonic sound began to be turned

to dozens of industrial tasks.

Both Sperry Products and Firestone Tire and Rubber were early users of ultrasonic

waves as flaw detectors. Ultra-sound travels readily through solids, but with difficulty

through air. Beam a small ray of ultrasonic energy through a piece of steel, and

if an air bubble is present, an echo comes bounding back. The time the echo takes

to return shows an operator where the bubble is. Firestone originally used this

technique to spot defective tires. Today, it's standard practice with manufacturers

of parts ranging from locomotives to ball-point pens.

The Field of Medicine. Perhaps the most dramatic post-war gains

in ultrasonics took place in the field of medicine. One of the first doctors to

use the new therapy in the U. S. was Dr. John H. Aldes of Los Angeles. A few years

ago, after tests on himself and his co-workers, Dr. Aldes tried ultrasonics on a

patient, a 67-year -old widow, so crippled by one type of arthritis that she had

to be carried into his office. Dr. Aides applied treatment after treatment, but

nothing happened. He was almost ready to give up when the woman suddenly noticed

that she could move one hand a little. A few months later she walked into Dr. Aides'

office under her own power.

Today, ultrasonics is standard treatment for certain kinds of arthritis in hospitals

all over the country. It never cures, of course, since there is no known cure for

arthritis. But it does frequently bring dramatic relief from pain and it can limber

joints after all other treatment has failed.

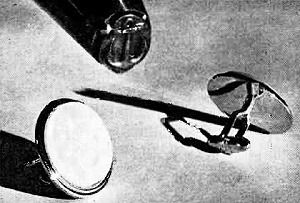

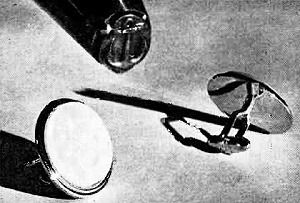

Mother-of-pearl intaglios for these cuff links were machined

from the tool shown above the set with an ultrasonic device. Jade, spinel, agate,

synthetic ruby, sapphire, onyx, and other stones can also be inexpensively worked

into beautiful jewelry by means of ultra-sound. Raytheon

Technician checks thickness of Explorer satellite nose cone with

ultrasonic gauge. The sharp vertical line on the scope face indicates thickness

to within one one-thousandth of an inch. Branson Instruments

In recent years, medical uses for ultrasound have multiplied. A woman's hand,

severely lacerated during childhood, was so covered with stiffened scar tissue that

it was completely immobile. Doctors at New York's Mt. Sinai Hospital shot ultra-sound

into the hand. The scar tissue softened within weeks, and the hand became useful

for the first time since her childhood.

An ultrasonic dentist's drill has been tested in the Air Force, and patients

report less pain than with conventional drills. Some types of brain surgery - using

powerful, tightly focused beams of ultra-sound to destroy pinpoint areas deep within

the brain - have also been successful.

One novel use: a slim ultrasonic transducer has been installed in a catheter

- a tube that can be inserted deep into our bodies. The transducer is guided until

it nudges a gall or kidney stone, then turned on. Like an ultrasonic drill, the

minute but fierce ultrasonic pounding painlessly batters the stone to powder so

that it can be eliminated with normal body wastes. Up to this time, such stones

had to be removed by surgery.

Other Successes

While accounts of current accomplishments of ultrasonics continue to mount, scientists

find new applications almost daily. Among recent ones:

Experiments show that one of the oldest problems of the sea - barnacles on ship

bottoms - may be solved by ultrasonics. Give the hull a continuous low-power dose

of ultrasonics, and the barnacles find it too uncomfortable to settle down.

Finer grain films have been made by subjecting the liquid emulsions to a shot

of ultra-sound before they harden. The sound breaks the particles of silver halides

into even tinier particles. Sharper, clearer pictures are the result.

One company has perfected a way of using powerful beams of ultrasonic sound to

sterilize foods after packaging, doing away with the need for heat or other conventional

preserving techniques.

So numerous are the applications of ultrasonics that it's anybody's guess as

to what's next. But you can be sure of one thing: even the sky is no limit for the

magic of silent sound!

Ultrasonic Primer

An ultrasonic generator is nothing more than

a signal generator (much like the one on a radio-TV workbench, only designed to

cover a different frequency range), plus an amplifier, and a transducer. This last

item is a gadget which converts electrical energy into sound waves. The speaker

in your hi-fi setup is a transducer and does the same job, although at different

frequencies. An ultrasonic generator is nothing more than

a signal generator (much like the one on a radio-TV workbench, only designed to

cover a different frequency range), plus an amplifier, and a transducer. This last

item is a gadget which converts electrical energy into sound waves. The speaker

in your hi-fi setup is a transducer and does the same job, although at different

frequencies.

There are two kinds of ultrasonic transducers in general use - piezoelectric

and magnetostrictive. In the first, an oscillating current is applied to a crystal,

which vibrates, sending out ultrasonic waves. The magnetostrictive head, by contrast,

takes advantages of the fact that certain metals - nickel, for example - will expand

and contract in the presence of a magnetic field. Surround a nickel rod with a coil

hooked to the output of an oscillator, and the bar expands and contracts at the

oscillator's frequency rate, again setting up ultrasonic vibrations.

Ultrasonic generators range in power from a few watts for flaw testing, thickness

gauging, and similar uses, up to as much as several thousand watts for heavy industrial

cleaning, drilling, and so on. Frequencies used in most industrial processes range

from 20 to 50 kc., since it takes considerably more power above that rate to do

the same job. Medical applications, however, often use sound in the 500-kc. to 3-

or 4-mc. range.

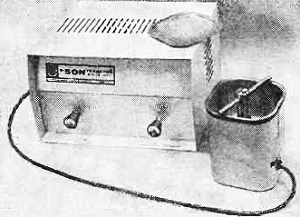

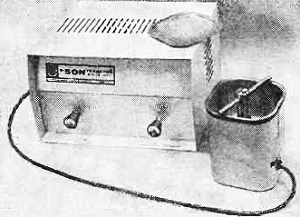

Low-Cost Cleaning Ultrasonics

Ultrasonic cleaning equipment is available in a wide variety of sizes, shapes,

and prices. The lowest priced item on the market as this is being written is the

"diSONtegrator System Thirty." Manufactured by Ultrasonic Industries, Ames Court,

Plainview, L.I., N.Y., it costs $69.95, complete. The diSONtegrator System Thirty

has a 30-watt oscillator operating at about 90 kc. Tuning is broad, and the ultrasonic

signal is basically FM. The oscillator is built around a single type 826 tube. A

one-pint capacity cleaning tank features a working compartment measuring 3 5/8"

x 3 5/8" x 3" deep.

This small ultrasonic cleaner has been used in the Popular Electronics laboratory

for several months. When employed with the proper detergent - ammoniated for glassware,

jewelry, eyeglasses, etc.; copper brightener for copper or gold; alkaline for rust

removal, etc., etc. - the unit performed with astonishing efficiency. Small electronic

parts that could not be adequately cleaned without disassembling were made to shine

as if brand-new. In fact, brand-new parts were cleaned also, to remove any traces

of soil left from packaging and shipping.

A slightly larger version of this low-cost model is available for $99.95. It

is called the diSONtegrator System Forty, and includes a one-half gallon cleaning

tank (measuring 5 3/4" x 5 1/4" x 4" deep).

Posted October 19, 2023

|

An ultrasonic generator is nothing more than

a signal generator (much like the one on a radio-TV workbench, only designed to

cover a different frequency range), plus an amplifier, and a transducer. This last

item is a gadget which converts electrical energy into sound waves. The speaker

in your hi-fi setup is a transducer and does the same job, although at different

frequencies.

An ultrasonic generator is nothing more than

a signal generator (much like the one on a radio-TV workbench, only designed to

cover a different frequency range), plus an amplifier, and a transducer. This last

item is a gadget which converts electrical energy into sound waves. The speaker

in your hi-fi setup is a transducer and does the same job, although at different

frequencies.