|

June 1961 Popular Science

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early

electronics. See articles from

Popular

Science, published 1872-2021. All copyrights hereby acknowledged.

|

Most people, even in this, the

year of our Lord 2024, still use old-fashioned cylinder locks on a regular basis.

Your abode's front door lock is almost certainly a cylinder lock, as is the

starter lock for your car. You likely have a metal key in your pocket or purse

for each. If you have recreational vehicles, chances are they are started with a

metal key in a cylinder lock. Variations on the basic design of a cylinder lock

have emerged which make them more difficult to pick, but fundamentally they are

mostly the same. We have all seen movies and television shows where clever

crooks, police, and private detectives pull out a professional

lock picking kit and jiggle a lock in mere

seconds, no matter whether it is an office door, a file cabinet, or a bank vault.

This 1961 Popular Science magazine article provides a good introduction

into cylinder lock construction and operation. Of course videos abound on

YouTube for learning the fine art of

lock picking. If you

want a good laugh, watch

this.

How a Cylinder Lock Works

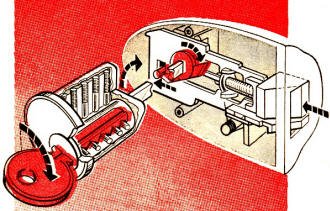

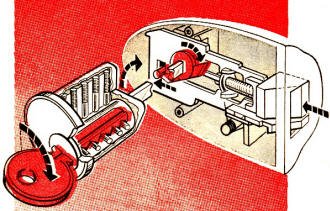

Key Part of a pin-tumbler cylinder lock is a cylinder or case

with an off-center hole. A plug slotted to receive the key turns in this. Drilled

cross-wise in both cylinder and plug, and aligned when the key is out, are five

small holes. Each contains a round-ended pin and a similar flat-ended driver. When

they are in line (key is shown turned at left) the pins are pushed into the keyway

by small springs. Inner end of the plug has a cam or a bar (as shown) engaging the

second lock element - the bolt mechanism. When the key turns the plug within the

cylinder, this cam or bar operates the mechanism, withdrawing the door bolt. Key Part of a pin-tumbler cylinder lock is a cylinder or case

with an off-center hole. A plug slotted to receive the key turns in this. Drilled

cross-wise in both cylinder and plug, and aligned when the key is out, are five

small holes. Each contains a round-ended pin and a similar flat-ended driver. When

they are in line (key is shown turned at left) the pins are pushed into the keyway

by small springs. Inner end of the plug has a cam or a bar (as shown) engaging the

second lock element - the bolt mechanism. When the key turns the plug within the

cylinder, this cam or bar operates the mechanism, withdrawing the door bolt.

Plug cannot be turned until each pin is raised to an exact height

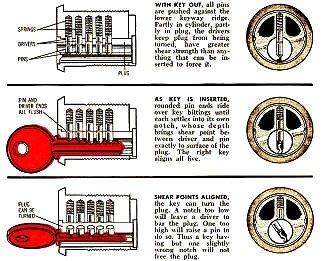

With Key Out, all pins are pushed against the lower keyway ridge.

Partly in cylinder, partly in plug, the drivers keep plug from being turned, have

greater shear strength than anything that can be inserted to force it.

As Key is Inserted, rounded pin ends ride over key bittings

until each settles into its own notch, whose depth brings shear point between driver

and pin exactly to surface of the plug. The right key aligns all five.

Shear Points Aligned, the key can turn the plug. A notch too

low will leave a driver to bar the plug. One too high will raise a pin to do so.

Thus a key having but one slightly wrong notch will not free the plug.

Invented by the Egyptians at least 4,000 years ago, the first pin-tumbler lock

was not a cylinder type. It had a bolt secured by concealed wooden pins. A key with

pegs spaced exactly like the pins raised them flush with the bolt, which could then

be drawn.

For centuries, locksmiths exerted ingenuity in other directions. Some bolstered

the security of poor locks with booby traps that cut off fingers, or trapped or

shot would-be lock pickers. Others added fake keyholes, or built in dual or triple

key movements.

In the 1860s Linus Yale Jr. patented improvements on a cylinder lock invented

earlier by his father, a builder of bank locks. The resulting Yale cylinder lock

was the first mass-produced one to offer real security, plus master-keying.

Top example of this is the system devised by Yale & Towne for the United

States Air Force Academy. Each cadet has a key that fits only his own locks. A sub-master

key opens all locks in one dormitory corridor. Increasingly large groups of locks

can be opened by master, grand-master, and great-grand-master keys.

A closely guarded great-great-grand-master key, available only to top-ranking

officers, can open any of the thousands of locks used throughout the academy. Details

of the system are secret, but the drawings below show the principle of master-keying.

Why a master key can open different locks

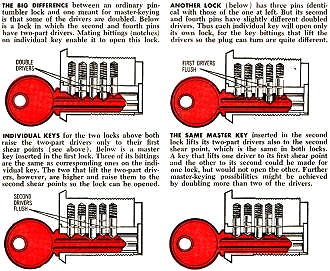

The Big Difference between an ordinary pin-tumbler lock and

one meant for master-keying is that some of the drivers are doubled. Below is a

lock in which the second and fourth pins have two-part drivers. Mating bittings

(notches) on individual key enable it to open this lock.

Individual Keys for the two locks above both raise the two-part

drivers only to their first shear points (see above). Below is a master key inserted

in the first lock. Three of its bittings are the same as corresponding ones on the

individual key. The two that lift the two-part drivers, however, are higher and

raise them to the second shear points so the lock can be opened.

Another Lock (below) has three pins identical with those of

the one at left. But its second and fourth pins have slightly different doubled

drivers. Thus each individual key will open only its own lock, for the key bittings

that lift the drivers so the plug can turn are quite different.

The Same Master Key inserted in the second lock lifts its two-part

drivers also to the second shear point, which is the same in both locks. A key that

lifts one driver to its first shear point and the other to its second could be made

for one lock, but would not open the other. Further master-keying possibilities

might be achieved by doubling more than two of the drivers.

Posted May 9, 2024

|