|

October 1949 Popular Science

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early

electronics. See articles from

Popular

Science, published 1872-2021. All copyrights hereby acknowledged.

|

Here is a really good

synopsis of "rare earth" elements that explains how they came to be known in

that way. Hint: It is not that they are so rare, in fact per Wikipedia,

Cerium is the

25th most abundant element on Earth. The issue is they are not in concentrated

lodes, but spread out as components of other mineral compounds, so extensive

processing is needed to isolate and purify them. One of the first post-war

commercial level extraction processes was the result of experimentations during

nuclear bomb research. As you might know, "holes" existed in the Periodic Table

of the Elements when it was first constructed in 1869 by

Dmitri

Mendeleev, because not all predicted naturally occurring elements had been

found. Helium, atomic

number 2, was not found on Earth until 1895, after first having been observed in

the sun's spectrum a few years earlier (hence its name, from Helios). Author

Alden Armagnac provides a primer in the original 15 rare earths (now 17) in this

1949 Popular Science magazine article.

Rare Earth Metals, Once Forgotten, Now in Production

Metals of atomic age may have names like praseodymium, thanks

to new process for purifying rare earths.

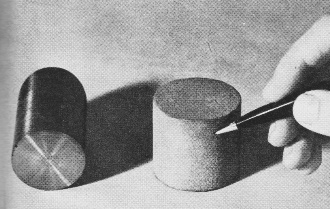

Worth 31 times its weight in gold, silvery praseodymium

metal in vial at left is sealed from air, which turns it black. One source of rare-earth

metals is monazite sand, above.

Glossy black portion of gadolinite ore, pointed

out above, also yields many rare-earth elements. Ore and one of metals, gadolinium,

are named after Finnish rare-earth chemist Gadolin.

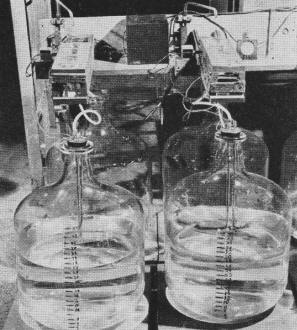

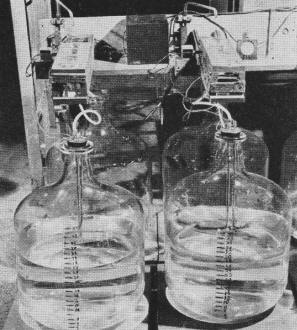

Ingenious control automatically switches output

of column from full to empty collecting bottle. Rising liquid trips electric circuit,

shifting carriage holding funnels and delivery tubes.

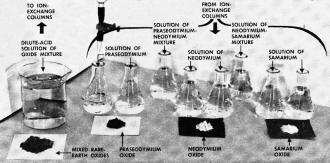

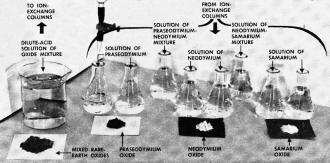

Pictorial diagram shows separation process at

a glance. Rare-earth oxide mixture, dissolved in acid (in beaker) goes into columns.

Rinsing with citric acid and ammonium citrate yields series of "fractions" in flasks,

of which last obtained is beneath delivery tube. From pure fractions, oxalic acid

precipitates oxalates, converted by heat to pure oxides shown.

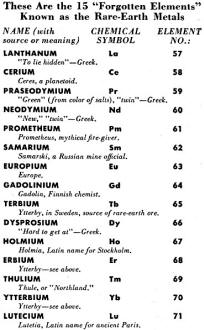

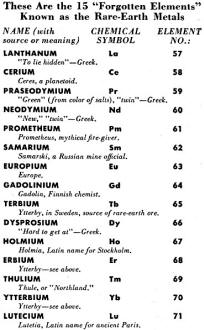

These Are the 15 "Forgotten Elements" Known as the Rare-Earth

Metals

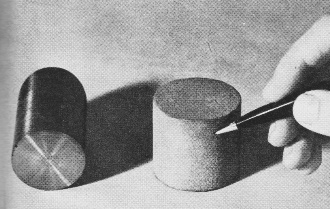

Air gives cerium, right, this cream-colored

coating. Freshly machined lanthanum, left, shines like steel. Each sample of rarely

seen metal weighs 1.3 lb. and is valued at $1,200.

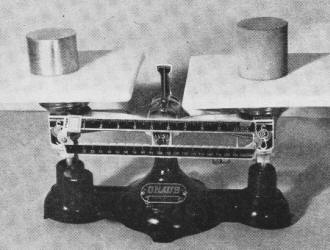

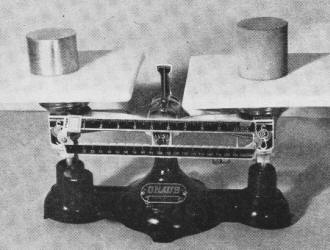

Rare-earth metals are only moderately heavy.

Cerium on right-hand side of scales, with density 6.8 times that of water, is balanced

by smaller piece of copper with density of 8.9.

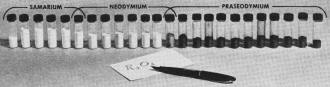

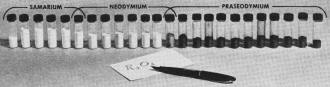

Yields of rare earths in oxide form, from series

of 12-hour runs through columns, show almost total separation of test mixture of

equal parts of samarium, neodymium, and praseodymium.

Results of another test show successful recovery

of neodymium and praseodymium from complicated mixture of other rare earths including

hard-to-separate gadolinium and samarium.

By Alden P. Armagnac

Spang in the middle of Iowa there's something nearly as tall as the corn - and

more exciting. It's a bank of glass tubes. Out of them come strange metals, some

of the most precious on earth, whose unusual properties may prove vital to the atomic

age.

They once were rarer than diamonds and actually priceless. Even now, being produced

in pound lots by a method born of the atom-bomb project, they cost up to 31 times

their weight in gold.

Few people have ever seen them. Gray to light gray with high metallic luster

at first, they turn odd shades on exposure to air - pale yellow, cream color, black,

grayish pink. Their compounds vie in brilliant hues with the colors of the rainbow.

Called the "rare-earth" metals, they are true chemical elements, just as iron,

copper, and silver are. Their names sound like something out of an apothecary shop

- lanthanum, cerium, praseodymium, neodymium, to mention a few.

Small wonder if the names are new to you. For the whole group of 15 rare-earth

metals, listed on page 143, might well be called the "forgotten elements." They

make up nearly one-sixth of the 96 known elements, the basic materials of which

all things are made. Yet a typical college textbook on chemistry, more than 1,000

pages long, devotes a scant two pages to them.

Practical uses have been as few in proportion. Just one may be familiar to most

laymen. Spin the wheel of your cigarette lighter, and you are striking fire from

pyrophoric, or spark-producing, rare earths, cerium metal in particular, in the

alloy of the flint. Lanthanum oxide goes into special optical glass for aerial-camera

lenses. Neodymium oxide absorbs glare in glass-blowers' goggles. Carbon-arc projectors

in movie theaters give an intense white light because of rare earths in the carbons.

There have been a few other uses for rare earths, but not many.

Today, however, these forgotten elements have become news. Atomic research has

focused the spotlight upon them. And under the direction of Dr. Frank H. Spedding,

Iowa State College chemist, the Ames Laboratory of the U. S. Atomic Energy Commission

has begun producing highly purified rare-earth metals and compounds in unprecedented

quantity.

One object is to see if they may be useful materials for future atomic power

plants - for instance, in control rods and in lightweight shielding against dangerous

radiation from atomic engines of ships and planes. Forming as "ashes" in uranium

rods of piles, rare earths have been a nuisance, tending to put out the atomic fires

by absorbing neutrons. But that very vice would be a virtue in shielding and control.

Dozens of these eight-foot-tall ion-exchange

columns, at Ames, Iowa, "refinery," accomplish feat of separating rare-earth elements,

which are almost identical chemically.

"Moreover," says the U. S. Atomic Energy Commission, "it now appears that they

may have a bright commercial future as alloy metals in the manufacture of high-temperature

structural materials."

It's partly the small proportion of rare earths in the earth's crust - there's

as much gold in sea water - that makes them "rare," not scarcity of places where

they can be found. One widely distributed ore is the yellow-to-brown monazite sand

of the Carolinas, Brazil, Africa, and India. Norwegian mines furnish gadolinite,

a glossy black rare-earth ore, and others. Rare earths of commerce have been relatively

inexpensive "concentrates" or crude mixtures obtained from these ores. For example,

cerium for cigarette-lighter flints is a $4-a-pound commercial alloy known as "mischmetal,"

consisting of cerium and seven other rare-earth metals, and other impurities.

But one of the biggest reasons the rare earths are so "rare" is their unusual

chemical resemblance to each other. They are so much alike that ordinary chemical

methods cannot separate one from the others. Years of tedious evaporating and re-dissolving

were formerly necessary to get a few specks of material.

Then in early 1944, workers on the atom-bomb project, including those at Ames,

Iowa, made the amazing discovery that rare earths formed by uranium fission could

be separated - in hours instead of years - simply by passing a solution of them

through a vertical tubeful of synthetic resin. Samples were, at first, sub-visible

"tracer" quantities; later, visible ones of ten-thousandths of an ounce.

Exciting news came from Clinton Laboratories at Oak Ridge, Tenn., when two young

chemists separated a mysterious substance from fission-produced neodymium with one

of the new resin tubes or "ion-exchange columns." It proved to be the long-missing

rare-earth element No. 61, which they named prometheum. Radio-active and short-lived,

it is believed non-existent in nature. First visible samples, pink and yellow smears

on white porcelain disks, are minute quantities of prometheum nitrate and chloride

respectively.

In the meantime, Dr. Spedding of Iowa State proposed as bold a step-up in scale

as that from a pinhead of plutonium to pounds of it for the bomb. Instead of being

content with "micro" quantities of pure rare earths, why not adapt the new method

to produce them in "macro" amounts of grams or even pounds? He and his colleagues

installed a battery of 24 resin columns, eight feet tall and four inches in diameter

- and made history by accomplishing the feat.

Watching the precious liquids trickle from glistening glass columns into collecting

bottles the size of cider jugs, a visitor to this pilot plant hardly realizes the

miracle taking place in the tubes.

Into the top of a tube goes a hodgepodge of rare-earth elements - re-dissolved

in acid after acid extraction from the ore and crude preliminary chemical separation

into two main groups, light and heavy.

Like flies to flypaper, ions - individual charged atoms - of rare earths stick

to the resin at the upper end of the tube. Thus they are strained-"adsorbed" is

the technical word - from the acid, which is then removed by washing.

Down Go the Ions

Now a dilute solution of citric acid and ammonium citrate is poured down the

column. Rinsed from the resin, or "eluted" if you prefer the scientific term, a

typical rare-earth ion starts down the tube. Almost at once it sticks to the resin

again. This skip-stop progress repeats itself, over and over, all the way to the

tube's bottom.

Eventually all the rare-earth particles reach bottom. But those of the element

of highest atomic number get there first; those of the next highest number, next,

and so on. Switch the liquid output from one collecting bottle to another, at the

right time intervals, and nearly every bottleful or "fraction" will contain a single

purified rare-earth element. A few fractions in which elements overlap are re-treated;

and purified fractions, if still higher purity is wanted, may also be run through

a column again.

The solutions yield oxalates, by precipitation with oxalic acid. Then heat treatment

converts these to the rare-earth oxides - the form desired for many experiments

and from which other compounds may readily be prepared. Purity runs around 99.9

per-cent.

By "smelting" rare-earth oxides when enough are on hand, the Ames workers produce

miniature ingots of the pure metals-tiny 1/20-oz. cylinders of silvery praseodymium

and neodymium metals, sealed against corroding air in helium-filled glass vials,

and comparatively massive 1.3-lb. chunks of cerium and lanthanum metals. Their weight

compares with iron, their softness with calcium; like the latter, they react with

water, liberating hydrogen. Producing one avoirdupois ounce of praseodymium costs

almost $1,000; of neodymium, $170; of lanthanum and cerium, $57 each - compared

with the $31.90 value of an ounce of pure gold ($35 per troy ounce).

If new uses require pure metals, even these prices - which the experimenters

hope to reduce - may not be commercially prohibitive. Like radium in watch dials,

a little may go a long way. Or like platinum in chemical crucibles, advantages may

outweigh cost. But it is primarily for research that scientists prize the newly

available pure preparations. At last their long-mysterious properties can be fully

explored for possible exploitation. The "forgotten elements" are forgotten no longer.

Posted April 16, 2024

|