An Avocation Becomes a Vocation

|

|

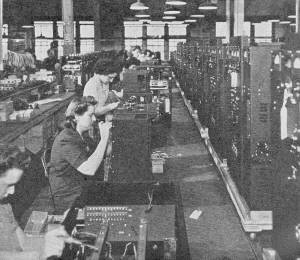

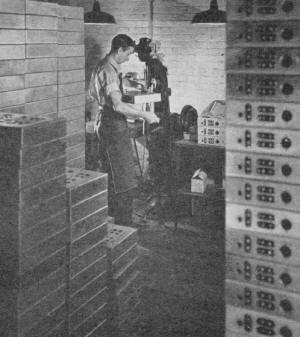

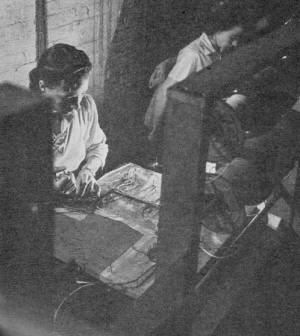

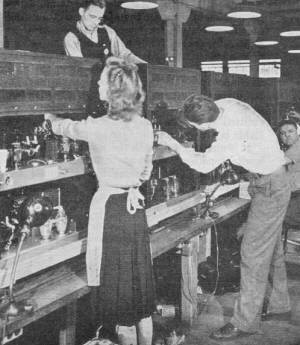

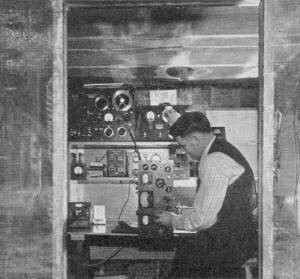

Did you know that the Hallicrafters line of radios is named after founder Bill Halligan (W9WZE)? Hallicrafters, founded in 1932, was a major manufacturer of amateur radio gear. During the years of WWII they ruggedized some of their products to survive the harsh environments of battle. Hallicrafters was sold to Northrop Corporation in 1966, at which time the product line essentially ceased. Their gear is still very collectible by aficionados of vintage Ham equipment. This story from the February 1943 QST magazine provided an inside look at the production floor at Hallicrafters. Having cut my figurative electronics teeth on radar and radio equipment built with tubes and point-to-point wiring while in the USAF, and then later as an assembly/test technician at Westinghouse Electric building sonar equipment for the Navy which included wiring chassis and building large complex cable harnesses, I can personally relate to the photos accompanying the article. When, for readers in the U.S., is the last time you saw a company touting its "expert American craftsmen" on an assembly line? The W9WZE.net website is dedicated to Hallicrafters' history. An Avocation Becomes a Vocation The Amateur Makes a Vital Contribution in the Manufacture of Military Radio Equipment By Herbert W. Hamilton,* W9MRQ It would be difficult to find another peace-time hobby that could be converted to all-out war production in a way to compare with amateur radio. The very fact that our American backlog of trained radio personnel was found ready and able during past emergencies has set the stage for our present critical situation. Once again the amateur has been given the opportunity to serve a cause, not only in the Signal Corps and the other services but, equally important, as part of the group whose job it is to supply our fighting forces with the finest radio communications equipment that can be produced. Transmitters by mass production. On the assembly line at the left individual units are carefully tested for continuity of wiring and correct cabling by skilled girl operators. After testing, all necessary adjustments are completed before the chassis units are mounted in the transmitter cabinets. At the right is a row of complete transmitters. fully assembled. tested and ready for shipment to our armed forces. Note the final inspection tags attached to the front panel. These sturdy metal chassis will support parts of highest quality and will be wired by expert American craftsmen - many of them amateur radio operators. All holes must be free from burrs or rough edges that could cause damage to the wiring system. Insulated wires of various colors are wound about headless nails. They designate the exact position where a connection will be made. Later they are carefully laced together with heavy waxed cord. Each "breadboard" is marked with an identifying number. This YL is putting the finishing touches on a transmitter cable. Inspectors examine each completed unit and check to determine whether or not the cable will meet government specifications. The spools of wire on the rack in the foreground show why copper is so badly needed! Heavy transmitter chassis are held at a convenient angle for wiring on special wood frames. Each operator is responsible for completing a designated series of connections in a prescribed order. This steps up production and prevents mistakes due to complicated circuits. Transmitters being assembled on one of the many assembly lines. Heavy tables support the tremendous weight of the units. Girls as well as men play an important role in production. Many of them will be among tomorrow's hams. Transmitters are placed on dollies to facilitate being moved along the assembly lines. The YL in the foreground is inserting transmitting tubes in a completed unit. After continuity tests are made it will be sent along to the inspectors and testers. A familiar model is this receiver, here seen undergoing a series of tests in the Hallicrafters laboratory. Military sets of similar design successfully withstand terrific punishment when used on our battlefronts. Each transmitter receives its "baptism of fire" before being packed for shipping. Precision equipment is used for these important tests and actual testing must be executed by skilled radiomen. Many are licensed amateurs. Shielded test booths are an important part of a modern radio plant. Outside QRN cannot be tolerated while critical adjustments are being made. Grounded copper screen completely encloses each test room. Thousands of amateurs are now in the armed services, carrying out their missions with traditional fortitude. Their long experience in peace-time emergencies has given them pre-training in the art of handling traffic and in the maintenance of equipment so that there will be no interruption in the transmission or reception of vital messages. Recent articles in QST have given us a picture of the part that these amateurs are playing on the fighting front. What about those on the home industrial front? The combination of manufacturers and homebuilders has been of tremendous importance in the job of turning out military equipment to "get the message through." If it were not for the fact that American radio manufacturers had been producing transmitters and receivers for amateur radio operators throughout the world, the job of setting up plants and the training of personnel for the vast requirements of war would have been most difficult. Radio men are not made overnight. Like the family doctor, a certain amount of basic training is essential. Furthermore, a radio man does not become skilled in mechanical and electrical operations simply by reading a textbook. He must acquire a technique whereby he can use his common sense and ability to diagnose minor troubles by the simple process of "sight" or "smell." Amateur radio having been in existence for many years, there are among its thousands of participants a large number of "deferred essentials" and III-A men who can devote their time to the construction, design and other duties associated with the production of military radio equipment. Hundreds of them are engaged as engineers, purchasing agents, servicemen, phasers, testers, shop foremen and in executive capacities. It was fortunate for the nation that these men understood the requirements for continuous duty on the field of battle and were able to undertake the construction of new military sets and build them to government specifications. The amateur has been an important factor in making our war production of radio materiel what it is to-day. Radio Production Converted to War Needs The production of radio equipment for public consumption was ordered to cease last April. Little time was lost in converting manufacturing plants to all-out production of equipment for our growing military machine. It is a matter of record that many of these factories are now flying the Army-Navy "E" flags high above their plants. Overnight these plants increased their production capacity many times. New tools and machinery replaced older machines not suited to the arduous task of day and night operations. New methods were adopted which save valuable hours in turning out an elaborate transmitter or receiver. Better parts and tubes made it possible to standardize so there is no needless waste and so that replacement of a damaged part will be made easier - particularly on the fighting fronts, where speed is essential in the maintenance of communications equipment. There can be no failures when lives are at stake. That is why Uncle Sam has placed so much confidence in American radio manufacturers. They are doing an outstanding job. Perhaps the best way to see how this job is being done is to go on a tour around one of these plants and take a look at the actual processes of manufacture. A logical choice for such an inspection trip is the Hallicrafters plant in Chicago - logical not only because before the war it was one of the world's largest manufacturers of amateur communications equipment, but because it is now producing such a large volume of military equipment based on these amateur designs. In fact, right there lies one of the major contributions flowing from amateur radio to the war effort. The Hallicrafters make much special equipment based on new developments for military needs, of course, but the greatest part of their production is in transmitters and receivers the basic design of which was originally created to meet amateur needs. It is significant that this "amateur" gear - some of it designed as long as four or five years ago - is now given top rating by the armed services for military needs. The fact that this amateur-type equipment has been selected by the military, often in competition with the best of the specialized commercial designs, is a striking commentary on the discrimination and technical achievements of the American amateur fraternity. It will be a strong chapter in our record when the war is over and the details can be told. Mass Production of Military Radio Equipment The accompanying photographs are illustrative of the many tasks performed in the 24-hour a day production of military radio equipment in the Hallicrafters plant. The various mechanical and electrical operations in building a transmitter or receiver are most interesting to the observer. Large metal chassis are carefully drilled to close tolerance. Any burrs left on the chassis must be removed during this operation in order that wires will not be cut. Every chassis must be protected against rust or corrosion; this becomes most necessary when units are sent to damp climates or for operation on naval vessels. Many improved formulae have been developed for plating and otherwise protecting the metal surfaces. Electrical conductivity has been improved, eliminating many of the older set noises. Small parts such as terminal strips are riveted in place. Nameplates are attached and stamped with the model number and other information required. The larger parts, such as transformers. condensers and inductances, are then bolted or otherwise fastened in place, and the assembly is ready for wiring. Radio equipment made for continuous service must be wired by skilled hands. The adoption of color-coded cabling is an important contribution to simplicity in wiring or servicing complicated circuits with their maze of connections. Large boards, slightly bigger than the chassis, are used breadboard style for the preparation of these multi-wire cables. Nails with heads removed are driven into the boards at the spot where a turn is to be made or where a socket or other part is to be connected. Various colors indicate the particular classification of circuit, such as filament, plate, cathodes, etc. Most grid circuits are omitted from the cable - for obvious reasons. Cable boards are marked for identification. It is amazing to watch the women who do this work prepare an elaborate cable in a few moments' time. They become highly skilled and rarely make a mistake. Inspectors examine each cable after it has been completed, before it goes to the wirers. There is a right and wrong way to wire a radio receiver. Each operator must follow a prescribed procedure in order to avoid confusion with the balance of the assembly line. Special racks are constructed to hold the working chassis at a convenient angle for good visibility during the wiring procedure. Each operator has a designated series of wires to connect. The number of operations on the assembly line is dependent upon the complexity of the set. Techniques are developed to do the job in the shortest possible time and with the most consistent wiring finesse. Amateurs on the Assembly Line Many of the experts employed in the construction of this equipment hold amateur licenses and have had plenty of experience in the construction of their own gear. When they return to the air it is certain that their equipment will not break down due to faulty wiring or mechanical failures. We predict that many of them will contribute in no small measure to the new radio art that is to follow the war. The radio bug has also bitten many of those engaged in the produc-tion of equipment who have never had any part in amateur radio. Their training will aid them greatly to get on the air when amateur operation is resumed. Women are playing an increasingly important part in supplying the military with radio units. Delicate operations are executed in quick time by their nimble fingers. With the adoption of ultra-compact sets, we expect many of these YLs to design and develop highly efficient gear for their own stations after the war. The activity of amateur personnel is not limited to the construction of receivers. We find many of them on the transmitter assembly lines. One of the photographs shows a group of employees busy assembling high-powered units for service where several frequencies must be available at a moment's notice. Modern engineering has resulted in tremendous improvements in this type of transmitter. After hostilities, the amateur will be given the opportunity to take full advantage of these late developments. New methods for switching tank coils, new and improved means for neutralizing, smaller and better components, stabilized crystal oscillators, economical tube operation and many other features are most intriguing. These must remain a secret until final victory is won. The men and women who are in contact with these late developments will be among the first to enjoy the new equipment at their stations. Many hams have in the past been a bit careless in constructing their own rigs. The American manufacturer has been responsible in many ways for changing the entire technique in assembly, layout and wiring of units. Bad habits have been corrected. Building a large transmitter, for example, is done by following a carefully-planned system. Heavy tables equipped with steel rails permit these bulky units to be moved along the assembly lines in orderly fashion. Each operation is conducted with precision by men and women especially trained to do their job in as short a time as possible. Experience has shown that the radio amateur is particularly well-suited to almost any operation that may be assigned to him. In making these large transmitters each assembly line is charged with the responsibility for turning out individual sections. A portion of one of these lines is shown in one of the photos. These units, after receiving final tests and inspections, will later be placed into their steel cabinets. Final tests are conducted with extreme care. Actual on-the-air conditions must be simulated in order to observe the conduct of the transmitter under full operating conditions. Tubes must be carefully checked and tested with overloads to insure that they will not fail while in service. Amateurs selected for these responsible jobs have the ability to detect any fault in operation by a glance at the various indicating instruments. Here is where experienced operators must be employed. Students having completed a short-cut radio course cannot possibly have gained enough background to be able to assume responsibility for so important a job. The United States was fortunate in possessing the great majority of the world's radio amateurs and skilled radio technicians. These men and women were accustomed to the tedious tasks met in the design and construction of complicated sets. They had learned that patience was a virtue, and that the pace set by the American ham was the envy of the entire amateur world. If it were not for these 'phone and c.w. hounds, we would not have the radio equipment we now possess. New Techniques Up to a few years ago most amateurs assembled and wired their own receivers. Some of them were very efficient and reliable; others were not. The American manufacturers of communications equipment undertook to design highly-efficient sets that could be offered to the amateur at little more than the cost of a homemade unit. Bugs were eliminated and many improvements added that could not be handled in the average shack. The result was a trend to purchase ready-made sets in preference to others. We hams will never be satisfied with a mediocre receiver in our shacks. We would rather layout a few extra bucks now and then in order to acquire the latest sets that are more selective, equipped with better crystal filters and possess all of the other refinements needed to combat the heavy QRM that existed on our crowded bands prior to the QRT order. That trend toward manufactured equipment has paid huge dividends in our war effort. Thousands of sets were available from jobbers and operators for military use that would not have been on hand were it not for this trend. Not so long ago an urgent plea was sent out by the Signal Corps and other services asking owners of standard manufactured sets to offer these to the government at a fair purchase price, to be used in our training centers. Only those sets having diagrams and instruction books were included. It would have been sheer folly to accept units that were not duplicates of others or lacked pertinent information that could be used to insure continuous duty. Thousands of hams responded by giving up their cherished sets. Today the old set is giving yeoman service where it will do the most good. Thousands have been shipped abroad, and many of them appear in photos received from our fighting fronts. The demands of the military have resulted in new designs and innovations. These will be incorporated in the new sets that will find their way into thousands of radio shacks after the war. Some of these late developments are most revolutionary. The panoramic technique alone offers unlimited possibilities for accurate tuning of DX stations. One manufacturer is even now keeping pace with the military sets by incorporating many of the new ideas into experimental sets designed for post-war amateur radio. This foresight should offer much encouragement to those who are wondering how long it will take to return to "normal" when the last shot has been fired. Hams in the Labs The typical American radio laboratory staff includes many hams. In times of peace they are charged in designing new equipment for one of the greatest hobbies known. The testing, alignment and other operations were performed by amateur radio operators in hundreds of laboratories. These men had learned the importance attached to the manufacture of sets for use in peace-times and it was comparatively easy for them to take over the responsibility of making precision adjustments on sets tagged for Uncle Sam's forces. A visit to one of these radio plants puts us in contact with many hams that you have talked to on the air. At the Hallicrafters, for example, we find Bill Halligan, W9WZE, one of radio's old-timers, president of The Hallicrafters. When bombs fell on Pearl Harbor, his company, like many others, possessed a large group of skilled craftsmen engaged in building transmitting and receiving equipment of many types. Among them are Herb Hartley, W9WNG; Cletus Wiot, W9TDF; Donald Wilbur, W9BRT; Clarence Zorn, W9TAL; Wallace Burandt, W9PTD; Fred Connor, W9CUK; Jack Cappels, W9EPB; Ray Polkingham, W9IAV, and Jack Pekasovich, W9LOL - to mention only a few. All are applying their technical and executive knowledge to the war effort. They realize that the further pursuit of their radio hobby can only be guaranteed by a final and complete Allied victory. Yes, an avocation has become a vocation to thousands of men and women. They are turning out the finest radio equipment that can be made. Army and Navy inspectors - also including many amateurs - are seeing to it that there will be a steady supply of transmitters, receivers and other special equipment reaching our fighting men wherever they may go. They also know that the future of their hobby depends entirely upon ultimate victory for the Allies. Without that victory, there can never be a return of our avocation.

Posted April 27, 2023 |

|