|

March 1967 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

Have you ever heard of a

"Joy bomb" in regard to encapsulation of semiconductors in plastic packages? It

took me a moment to figure out what the author was referring to when I read it

in this 1967 Radio-Electronics magazine article entitled "Plastic Transistors - The Future Billions."

Joy was (is) a household dishwashing

detergent that has been around since 1949. I still remember the corny "Lemon

Joy" commercials from the 1970s with people being utterly overcome with the joy

of seeing their reflections in the dishes cleaned in Joy... but I digress.

Although not explicitly mentioned, I assume a concentrated liquid soap was used because, as when pouring soap on a tire when looking for an air leak, a

visible bubble will form at the site of the breach. That was part of the initial

investigation into using plastic. We take for granted cheap

plastic packaging, but the transition from bulky, heavy, hollow metal cans which

were vulnerable to vibration, to small. lightweight, fully encapsulated packages

that capture the wirebond connections greatly improved affordability and

reliability.

Plastic Transistors - The Future Billions

This mold is used for compressing the transistor into a rock-hard plastic capsule.

The newest type of solid-state package.

By Keith W. Bose

The growth of solid-state technology from the early days of germanium to the

silicon field-effect transistor has been marked by lulls and spurts of activity.

Now there is another surge of action caused by the introduction of a line of low-cost

solid-state devices with plastic encapsulation. The use of plastic makes possible

a dramatic price drop in transistors, thus opening new areas to electronics. Industry

leaders are saying that by 1971 the world will use close to two billion plastic-encapsulated

semiconductors.

A silicon field-effect transistor with a retail price of only a dollar is some-thing

to think about! The availability of such a low-cost device means more electronic

applications in the automotive field. Safety devices and driving aids are simpler

to manufacture, for instance.

The immediate use for plastic transistors, however, is probably in hi-fi, TV

and electronic organs. One amplifier manufacturer reduced his selling price by two-thirds

and found that his sales quadrupled. Even the voracious appetite of computers for

solid-state devices is being satisfied with the technique of plastic encapsulation.

Plastics engineers climbed a long hill before airtight plastic packages became

a reality. After 3 years of experience with the technique, engineer George Berryman

of Texas Instruments says that "we have found plastic units as reliable as their

counterparts in metal cans."

The plastics involved are derivatives of epoxy, that familiar hardware-store

glue that provides rock-hard bonding between almost any two substances.

The big problem in transistor manufacture was getting a package that could completely

seal off air. This sounds easy, but for chemical reasons it's difficult to form

a tight bond between plastic and metal. This bond is necessary where the transistor

leads enter the case. It is often said that the semiconductor art has two phases-growing

the chip, then packaging it so it will operate. Some solid-state manufacturers send

chips overseas, there to be packaged in areas of low-cost labor and then return

to the U.S.

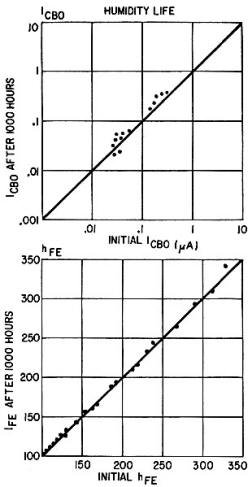

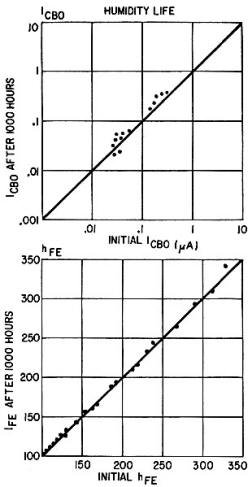

The effect of humidity on ICBO and hFE in a group of plastic

transistors. Straight-line before-and-after plots show stability.

Plastic-encapsulated semiconductors are manufactured by either of two processes:

the liquid or cast-molding system, or the transfer-molding system. The liquid system

uses a "header" of ceramic and plastic to hold the leads. This header is formed

from powdered glass and ceramic which is first compressed. A charge of ceramic powder

follows a charge of glass, followed by a charge of ceramic in a press die. The powder

is then compressed until the chemical binder sticks the whole mass together in a

solid form.

The presses used for liquid or cast molding are multiple rotary affairs. The

forms are "fired" after lead insertion to form a solid mass. The header, together

with the leads fused to it and with the chip connected, is covered with liquid plastic,

usually in a mold, then baked. The process is messy. Because the resin must be mixed

with a hardener just before use, only small batches at a time are mixed, and proportions

are carefully controlled.

Transfer molding is initially more expensive process, but for volume production

it offers more advantages. The process uses a dry-mix compound which is transferred

to a hot die by heat and pressure. In the process the mixture goes from a solid

to a liquid and then back to a solid state. When finished, the chip is surrounded

with only one substance - the plastic - and the leads and bonding wires are embedded

to form a highly reliable unit.

When a completely new product is developed, some assurance of its reliability

must be established. One way to check reliability is simply to sell the product

and wait for the customers to scream. This is certainly no way to keep customers

or to introduce new products. The safe method is a laboratory test program. Plastic

semiconductors have been heated, cooled, pounded, dropped, and given all sorts of

rough treatment. Areas of reliability testing are resistance to moisture and the

ability to withstand thermal and physical shock. One other consideration is possible

damage to the chip by the plastic itself.

Moisture resistance is tested by using what's called a "Joy bomb." A semiconductor

is sealed into the "bomb" along with detergent solution. Hydrostatic pressure then

forces moisture through any leaks. The new plastics pass this test with flying colors.

Humidity resistance is tested in a "bowser box" - a test chamber in which temperature,

humidity and pressure may be precisely controlled. A common ritual for semiconductor

testing is 1,000 hours or longer at 90% relative humidity and +45°C.

In many circuits it is important for a transistor to maintain its parameters

within certain limits over long periods of operation. The graphs show a "scatter"

plot of ICBO and hFE for one transistor after 1,000 hours

of back bias at elevated temperatures and high humidity. The 45° lines represent

no change from initial readings. Note the close grouping around this line, showing

excellent stability. One company - Texas Instruments - has gathered reliability

data from 2 million hours of test operation. It appears that plastic semiconductors

are here to stay and, what's more important, at low prices.

As an example of the low cost of plastic transistors, the small-quantity retail

price of the 2N4419 is in the neighborhood of 50¢. This device is one of a

line of npn/pnp high-speed low-level switches.

Another good example, now available in quantities of 1-99 at $1.50 each, is the

TIP24. Just for comparison, when silicon transistors were first made, around 1960,

they sold for $15 or more.

The TIP24 is a 2-amp epitaxial-planar silicon power transistor. It could be a

boon for audio. A pair of TIP24's will easily deliver 20 watts. The devices will

sell in pairs matched within 20% (IC = 1.5 amp) assuring minimum distortion

in class-B operation. A mounting tab serves as the collector lead of this double-ended

low-profile package. This feature allows mounting with only one chassis hole and

a sheet-metal screw. In production, it is possible to form the leads and tab for

special mounting requirements. Good beta linearity and low saturation voltage is

claimed for this transistor, when operated on a 70-volt supply and delivering 10

watts, with 167°F case temperature. With both high voltage and high current,

good speaker matching is claimed.

Another low-cost transistor, usable as an oscillator, a multivibrator, a wave-form

generator or an SCR trigger, is the TIS43. This one will withstand an acceleration

of 60,000 times the force of gravity!

Both silicon and germanium transistors are being encapsulated in plastic. Silicon

types are valuable because of their reliability. Their high-temperature characteristics

are valuable in places like auto radios and solid-state ignition systems where temperatures

soar on hot summer days. Germanium can still turn in the best record for performance,

however, and for lowest cost it is still the leader.

Plastic economy packages are available in both silicon and germanium transistors,

field-effect transistors, unijunction transistors, power transistors, silicon rectifiers

and integrated circuits. Plastic transistors can be mounted flush on PC boards,

reducing the possibility of shorts from excess solder and other production mistakes.

One-piece construction leads to increased reliability.

A new plastic IC family of 11 digital circuits (designated 15830N) includes multiple

gates, buffers, expanders, binary elements and a one-shot multivibrator. Plastic

encapsulation reduces the price of these circuits 25%. Shock and vibration resistance

and heat dissipation of these plastic IC's are excellent. The leads are in two rows,

spaced 0.3-inch apart and the units are designed for high-speed automatic insertion

in PC boards or chassis.

In production quantities the TIXM-12 costs only $1. This is a germanium planar

field-effect transistor for vhf mixers and amplifiers. It has low cross-modulation

distortion, with a noise factor of 2 dB at 10 MHz.

National Electronics, Inc. (a subsidiary of Varian) is now producing a new low-cost

readout driver using plastic transistors. Because the price has been reduced, many

industrial users will now be able to use readouts on their production lines. Formerly

such devices were considered luxuries by many small industrial plants.

Engineers are saying that there are exciting possibilities in low-cost field-effect

transistors. The FET has, of course, a number of advantages over both vacuum tubes

and junction transistors. It's high impedance makes it useful in many circuits where

ordinary low-Z transistors couldn't be used. Furthermore, the output impedances

of the source and drain circuits are roughly the same, which is not true of tube

plate and cathode circuits.

Plastic encapsulation of FET's increases their reliability and lowers their cost.

These are two reasons for predicting that FET's will be used more and more in the

next few years. Epoxy capsules seem a major step forward in solid-state technology.

Posted October 30, 2023

|