|

May 1958 Radio-Electronics

[Table

of Contents] [Table

of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

Breaking news from May 1958:

"Hardly a month passes nowadays without the announcement of some 'sensational' new

amplifying device. The great majority of these startling inventions, after their

brief flurry in the popular and technical press, disappear into oblivion. But we

believe that the Tecnetron,

just announced in France, has a brilliant and enduring future." Have you ever heard

of a Tecnetron? I didn't think so; neither had I before reading this article in

Radio-Electronics. I guess that pretty much negates the preceding prediction. The

holy grail of the Tecnetron, whose etymology in and of itself is worth reading about

(it's not what you would guess), is that its transconductance increases with frequency.

Construction is such that although it is fabricated from a shaped rod of germanium,

it has a current controlling component that acts like a cross between a triode vacuum

tube and a depletion mode field effect transistor. My guess is that the rapid improvement

of standard semiconductor junction field effect transistors rendered the Tecnetron

not just obsolete, but way too expensive to manufacture comparatively.

Great Britain Patent #GB941629A, "Tecnetron in semiconductor

devices," S. Teszner. Sept. 11, 1961

The Tecnetron: Competitor to the Transistor?

Neither spacistor nor transistor, this new semiconductor triode shows great promise

for the ultra-high frequencies

By E. Aisberg*

Close-up of a Tecnetron.

Hardly a month passes nowadays without the announcement of some "sensational"

new amplifying device. The great majority of these startling inventions, after their

brief flurry in the popular and technical press, disappear into oblivion. But we

believe that the Tecnetron, just announced in France, has a brilliant and enduring

future.

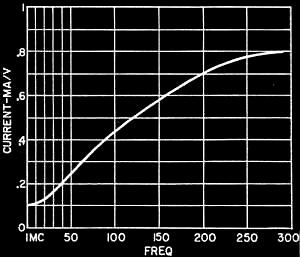

The most remarkable feature of this device i that it transconductance increases

with frequency, unlike more common semiconductor amplifiers whose performance falls

off as frequency increases and becomes very low as the cutoff frequency is approached.

Up to the present, frequencies in the order of 500 mc have been attained with the

Tecnetron. And, as further work and research make it possible to reduce the capacitances

of the contacts and other parts of the montage, there seems to be nothing to prevent

it from functioning at 1,000 mc or even higher.

It has been possible - with a Tecnetron working in class A at 500 mc - to obtain

a power output of 30 mw, with a dissipation of 125 mw. Since the characteristics

of individual Tecnetrons are very consistent, one can envision the paralleling of

several identical units to obtain watts - or even kilowatts - of power. This may

make it possible to use Technetrons in applications requiring heavy currents.

A Tecnetron unit in its case.

In addition, the Tecnetron - though using germanium - is less sensitive to high

temperatures than the transistor. It will operate at temperatures 20°C higher than

will transistors. This should extend its field of applications considerably.

Neither is it a fragile experimental device that works only under laboratory

conditions. Pilot production by regular industrial methods had begun on a small

scale at the time of its announcement. About 700 units per month are being produced,

and indications are that production could quickly be increased to the thousands.

What is the Tecnetron?

First, why is it the Tecnetron? The first syllable of the name begins as does

that of its inventor, S. Teszner. The initials CNET follow. These stand for the

Centre National d'Etude des Telecommunications (National Center for the Study of

Telecommunications), that great ensemble of research laboratories sponsored by France's

Ministry of Posts, Telegraphs and Telephones. And of course the final syllable is

the conventional one for such electronic devices.

Now, how is the Tecnetron constructed? It is a small rod of n-type germanium,

2 mm in length and 0.5 mm in diameter, provided with two contact electrodes at the

ends. These must be of such material that they act solely like electrical conductors

and not like transistor junctions.

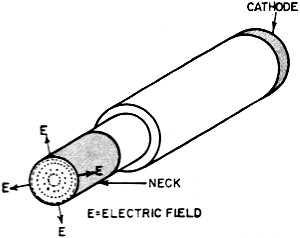

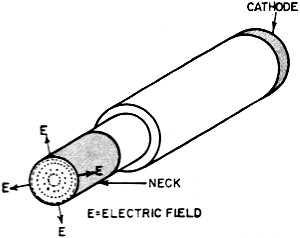

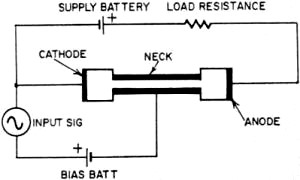

The germanium rod is reduced in diameter at its center (Fig. 1) to form

a "bottleneck" of very small diameter (about 30 microns). Around this neck is placed

a cylinder of indium. This makes a metal-to-semiconductor barrier-layer contact

of excellent characteristics. The ratio of forward-to-back resistance is greater

than a million to one.

Fig. 1 - Tecnetron cut to show cross-section of neck. The

space charge E tends to drive the conducting area toward the center of the rod.

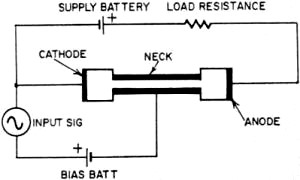

Fig. 2 - Schematic of Tecnetron hookup.

Fig. 3a - Distribution of charge carriers (electrons) with

neck unbiased; 3-b - reduction of current path caused by negative bias on neck.

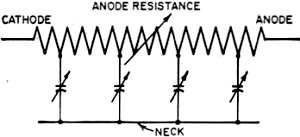

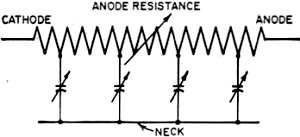

Fig. 4 - The Tecnetron can be considered as a variable resistance

and a distributed variable capacitance.

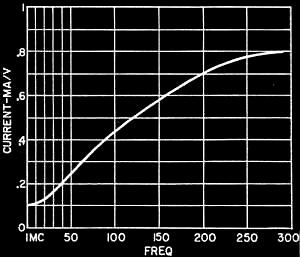

Fig. 5 - Variation of the Tecnetron transconductance as

a function of the signal frequency.

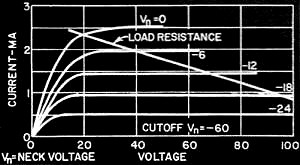

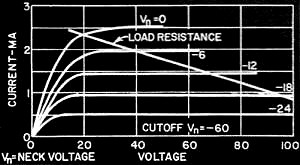

Fig. 6 - These Tecnetron static characteristic curves show

the variation of anode current as a function of anode voltage, for several neck

voltages.

A relatively high potential (50 volts or more) is applied to the electrodes at

the end of the rod. These may be called the cathode and anode. The cylinder of indium

might be called a grid, for it plays exactly that role. The inventor prefers to

call it the "bottleneck" or simply the "neck" to indicate its method of action better.

The neck is polarized negatively with respect to the cathode, and the circuit of

a stage of amplification (Fig. 2) is like that of a tube triode, with the load

resistance placed in the anode circuit in series with the supply voltage.

A field-effect transistor?

Is this device not essentially that which Shockley called a "field-effect transistor"

which he described in the Proceedings of the IRE (November, 1952; Vol. 40, pp 1365-76)

and with which he was not able to obtain appreciable gains above 2 mc? Like Shockley,

Teszner has turned to the field effect, discovered by Lilienfeld in 1928. Here the

resemblance ends. Whereas Shockley worked with plane surfaces (or a parallelepiped),

Teszner has utilized the cylindrical configuration, transforming a linear effect

to a quadratic one by applying a radial electric field.

What is the field effect? Our readers know of the Hall effect, due to which charge

carriers in semiconductors can be deflected from their paths under the action of

a magnetic field. The Lilienfeld effect is analogous to the Hall effect, but is

based on the action of the electric instead of the magnetic field. In semiconductors

such as germanium, charge carriers (electrons or "holes") can be deflected from

their paths by the action of such an electric field.

The Tecnetron action

The neck of the indium cylinder creates a concentrated electric field in the

interior of the rod, depending on the charge on the cylinder. With no charge whatever,

the current is propagated evenly through the whole area of the neck. As one applies

a negative voltage to the cylinder, the electrons are deflected toward the center,

occupying only a reduced section of the rod (Fig. 3). Thus the apparent resistance

of the rod increases as the active section - through which electrons pass - decreases.

This action is proportional to the square of the radius.

Note well that this is a variation in the total resistance, not in the specific

resistivity which remains constant.

The voltage applied to the indium cylinder causes the neck to act as if its diameter

were decreased. Thus the cathode-anode current is varied, causing the voltage across

the load resistor to reproduce faithfully the changes in the voltage applied to

the neck, but at a greater amplitude.

The best analogy of the Tecnetron is without doubt a flexible rubber hose through

which flows a current of water. If the hose is compressed more or less by the hand,

the flow decreases in the same ratio. If the hose is compressed circularly - from

all sides toward the center, as by an encircling thumb and forefinger - the diminution

of current will follow the square law. This centripetal constriction is an essential

characteristic of the Tecnetron.

Effects of capacitance

If we analyze these actions carefully, we note that the variation in resistance

is accompanied by a variation in capacitance between the part of the germanium occupied

by the electrons and the indium cylinder. As the cylinder becomes more negative,

it drives the electrons further from it and toward the center of the rod, thus reducing

the capacitance between the current-carrying portion of the rod and the cylinder.

As the voltage becomes less negative, the electrons flow through a larger section

of the germanium and the capacitance increases. The Tecnetron acts like the equivalent

circuit of Fig. 4.

These variations of capacitance, which are increased by the cylindrical configuration

of the device, have an effect on the current through the external circuitry similar

to that which the variations of resistance have on the flow of electrons through

the germanium. These two actions are synchronous and reinforce each other, thus

increasing the gain. There is of course a very slight detuning effect in resonant

circuits due to the instantaneous variations in capacitance produced by the signal.

These are very small, since the total input capacitance is a fraction of a micromicrofarad

and the detuning is proportional to the square root of the capacitance change. Practically,

according to the inventor, it manifests itself as a slight enlargement of the passband.

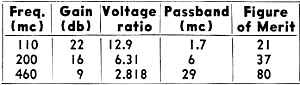

The capacitance effect, with its reduction of impedance as frequency increases,

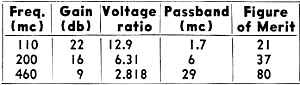

is one of the reasons for the high transconductance at high frequencies (Fig. 5)

and the fact that the Tecnetron's figure of merit continues to increase with frequency.

The figure of merit is the product of the gain by the width of the passband over

which the gain is maintained at ±3 db.

Tecnetron as amplifier

We have seen that the neck which acts as a control electrode is polarized negatively

with respect to the cathode. Thus no appreciable direct current can flow in the

cathode-neck circuit, because of the extension of the barrier layer into the n-type

germanium.1

Under these conditions, the input resistance is several megohms. The input capacitance

is in the order of 2 μμf.

The output impedance is generally higher than 1 megohm, and the load resistance

thus may be chosen as high as it is practically permissible to set it; usually between

2,500 and 250,000 ohms.

If we plot the characteristics of the Tecnetron by measuring the anode current

as a function of the anode-cathode voltage at various values of neck voltage, we

obtain a family of curves which resemble strikingly those of a pentode tube (Fig. 6).

Which is to say, that we have here an excellent voltage amplifier. The chart shows

experimental results obtained at various frequencies.

Manufacturing the Tecnetron

It was necessary to develop special technical methods to manufacture the Tecnetron.

This was one of the major achievements of M. Teszner and the CNET researchers who

aided him. For part of the work, the classic procedures of transistor production

could be followed. Then a whole series of new mechanical operations intervened:

cutting the refined crystals into plates, then into little rods. This last operation

was performed with ultrasonic cutting apparatus. The constriction for the neck was

made by a procedure of electrolytic etching perfected especially for the purpose.

The indium was also deposited by electrolysis, with the rod in continuous rotation

during the process. More conventional techniques could be used in applying the terminal

(cathode and anode) contacts.

Up to the present, procedures already developed permit manufacture on a large

scale. Research is continuing, however, and the next step is the creation of a power

Tecnetron and another model especially for ultra-high frequencies. Special arrangements

which will permit continuing still further up the frequency spectrum are also under

study. And, as always, as the area of actual accomplishment is increased, the greater

become the prospects of future progress.

* Publisher, Toute la Radio, Television, Radio Coustructeur et Deuarmeur, Eleetronique

Industrielle (Paris).

1 M. Teszner, Revue Génèrale d' Electricité, June,

1954.

Posted April 23, 2020

|