|

It seems that creating almost

cartoonish-looking antenna arrays for the purpose of signal gain and directivity

are usually relegated to the domains of military and amateur radio practitioners,

but this article from a 1952 edition of Radio & Television News magazine was

done by the Channel Master

Laboratories television antenna company. Successfully mounting and phasing even

two antennas can be challenging, but in this case four Yagis were arrayed and tuned

for operation. Trying to make the system work over the entire 4 octave band that

is the VHF broadcast realm (54 MHz for channel 2 to 210 MHz for channel 13) would

be nearly impossible without extremely complicated mechanical and electrical design,

so the engineers satisfied themselves with one channel at a time and used an adjustable

spacing scheme to accommodate all 12 channels. Extensive guying and bracing was

required to withstand wind loads. My guess is this "Supermount" never made it to

the production phase.

Stacking Four Z-Matched Yagis

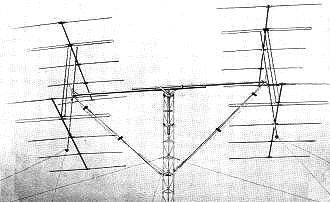

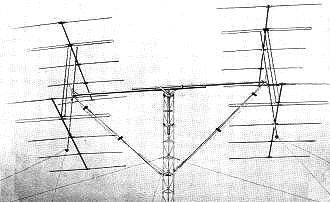

Fig. 1 - The new Channel Master "Supermount" antenna stacked

horizontally. The unit features adjustable structure.

By Harry Greenberg* and Harold Harris†

A new mechanical and electrical system incorporating a simple mounting arrangement

and a new impedance matching harness.

A practical system for stacking four Yagis by extending the principle of impedance

matching which led to the development of the "Z-Match" Yagi system has been developed

by Channel Master Laboratories. The resulting gains of over 14 db are the highest

yet attained in a practical television antenna.

The problem was of a dual nature because the mechanical problems were as formidable

as the electrical ones. For instance, if four-bay, half-wave vertical stacking were

attempted on Channel 2, the antenna array would require about 25 feet of unguyed

mast. On the other hand, on the high band, the length of masting required for four

bays is about 10 feet, which is a practical dimension. Therefore, a separate mechanical

approach was required on each band, although the electrical problem of phasing and

matching was the same. On the low band, the four-bay array was constructed by arranging

two stacked Yagis side by side. This arrangement was made practical by a new adjustable

structure made of heavy welded tubing (Fig. 1). This large mounting framework

was trade named the "Supermount,"

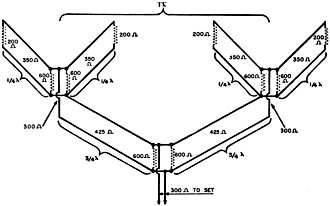

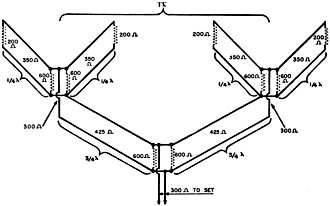

Fig. 2 - Operating principle of the four Z-matched Yagi

antennas.

The adjustable cross boom of the-"Supermount" provided for full-wave horizontal

spacing between the two stacked arrays. Since full-wave spacing was utilized, the

distance between the two stacked arrays ran up to 17 feet on Channel 2. The entire

structure was supported at the center. This meant that tremendous twisting torques

were developed under brisk winds. This torsion was excessive on most commercial

television towers because horizontal stacking narrows the directivity of the antenna

and makes it more sensitive to twisting. The twisting problem was solved by guying

the array at its outer extremities under each stacked Yagi. Guying at these points

also kept the guy wires out of the field of the antenna. These guy wires, in turn,

created a large downward thrust on the extended booms and this, in turn, was offset

by diagonal braces.

Since all of these operations had to be accomplished while assembling the entire

array from the top of a tower, the entire structure was designed in two parts so

that the spacing between stacked arrays could be adjusted for each channel and so

that the diagonal brace could be pivoted to fasten with a universal clamp at any

point of the tower. The cross booms are held in a section of tubing of larger diameter

so that the first Yagi of each pair can be put on, the connecting rods attached,

and then swung into the upper position by rotating the boom. Then the lower Yagi

is put on. The identical process is repeated for the other pair of Yagis. Before

discussing the electrical considerations in phasing and matching four Yagis, it

is interesting to note that the "Supermount" can be used for mounting stacked Yagis

of two different channels even though they require separate orientation.

Fig. 3 - The "Supermount' antenna stacked vertically. Because

the unit is adjustable. several arrangements are possible.

In the article, "The Yagi Antenna" published in Radio & Television News,

October 1951, the problem of matching a two-bay Yagi to 300 ohm line was discussed.

A system, subsequently named the "Z-Match" system, was described. In this system,

the single Yagi uses a three-conductor fold and by wider spaced elements is designed

to accurately match 300 ohm line. The impedance is dropped to 200 ohms by taking

out the center bar in the folded dipole. The center bars from the two Yagis are

then used as the linear matching transformers and they step the 200 ohm impedance

up to 600 ohms. The two 600 ohm impedances in parallel total 300 ohms and match

the line accurately. It is two arrays of this description which are to be stacked

in four bays. From the following, it will be evident that an accurate two-bay impedance

of 300 ohms is necessary.

In the case of the high-band Yagi is, the four arrays were stacked vertically

with half-wave spacing between each bay (Fig. 3). On the low band, the two

half-wave stacked arrays were spaced a full wave apart. Since these dimensions made

the use of a quarter-wave transformer impossible, and since half wavelengths of

line do not transform impedances, two 3/4 wavelengths of line were used. This length

has the same impedance transforming properties as a quarter-wave line. That is,

the matching impedance is equal to the square root of the input impedance multiplied

by the output impedance or  . .

Therefore, the problem resolved itself into the following considerations. We

knew that in order for the feed point of the entire four-bay array to match 300

ohm line, each two-bay antenna had to present an impedance of 600 ohms. These two

600 ohm impedances in parallel equaled 300 ohms which was the required impedance.

We also knew that each two bay "Z-Match" array had an impedance of 300 ohms. The

problem then was to transform the 300 impedance of each two-bay Yagi to 600 ohms

through the 3/4, wave transformer. Substituting in the formula

we get the following: we get the following:

, or Zm =

425 ohms. In other words, a 3/4 wave line having a characteristic impedance of 425

ohms will tie the two stacked Yagis into one four-bay array with all impedances

matched to 300 ohms. , or Zm =

425 ohms. In other words, a 3/4 wave line having a characteristic impedance of 425

ohms will tie the two stacked Yagis into one four-bay array with all impedances

matched to 300 ohms.

The entire system is shown schematically (Fig. 2). Electrically, the system

is the same whether the stacking is vertical or horizontal. Special 425 ohm harnesses

were developed for each band. On the high band, a self-supporting open-wire system

was used. On the low band, a special wide-spaced 425 ohm ribbon type transmission

line was developed because ordinary open-wire line was difficult to support on the

boom structure.

* Chief Electronic Engineer, Channel Master Corp.

† Vice-president, Sales & Engineering, Channel Master Corp.

Posted March 14, 2022

(updated from original post on 12/30/2015)

|

.

. , or Zm =

425 ohms. In other words, a 3/4 wave line having a characteristic impedance of 425

ohms will tie the two stacked Yagis into one four-bay array with all impedances

matched to 300 ohms.

, or Zm =

425 ohms. In other words, a 3/4 wave line having a characteristic impedance of 425

ohms will tie the two stacked Yagis into one four-bay array with all impedances

matched to 300 ohms.