Tube Testers for Speedy Checking |

||

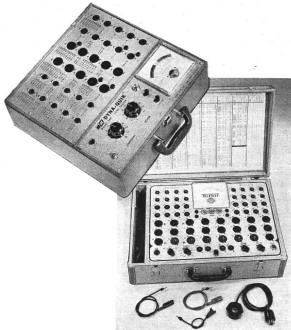

This is my personal B&K Dyna−Quik Model 650 vacuum tube tester It's a pretty good bet that most RF Cafe visitors are not overly interested in vacuum tube testers. Today they are collectors' items with some actually still being used for maintaining vintage electronics gear; however, in the days before semiconductor components they were the life blood of service men. Because tubes (aka "valves" in other parts of the world) are by nature one of the most vulnerable parts of any product in which they are used, often the first step in troubleshooting a radio, television, record player, etc., was to test suspected tubes for sub par performance. As mentioned often in Mac's Radio Service Shop stories, customers balked at service centers charging for their expertise but didn't mind as much paying for replaced components. That meant mark-ups on vacuum tubes comprised a large percentage of profit - which still wasn't all that much - for a service job. Electronics magazines of the era carried advertisements from multiple companies offering vacuum tube testers varying in complexity from versions which only worked for some of the most common part numbers to ones like those shown here in a 1955 issue of Radio & Television News that could check almost any tube made. When servicing in the home, time is money; these tube testers save service time. The two tube testers shown here check all of the popular tubes used in radio and TV sets. On the left is the B&K "Dyna-Quik." the one below is by TeleTest. Every service technician, whether he works for himself or someone else, is always running a race with the clock. Time is truly valuable and any instrument which permits a necessary job to be done more quickly than before, without impairment of accuracy, will always be of interest to the service industry. "Dyna-Quik" Model 500 Tester An instrument which is designed to speed up tube testing is the "Dyna-Quik", Model 500 tester, manufactured by the B & K Manufacturing Company of Chicago. This instrument is portable and operates on the Gm principle. It contains 30 sockets and will test close to 400 different types of tubes. Each socket will check only the specific tubes which are listed for that socket. The test procedure is to first locate the proper socket for a tube. At the bottom of the instrument panel there are two controls, labeled "Heater" and "Sensitivity." The proper settings for these controls are indicated with each tube listing. Once the controls are set, the tube is plugged into its socket, a "Test" button is depressed and the condition of the tube is revealed on the large 4 1/2 inch meter. The three indications are "Good," "?," and "Replace." If desired, the exact mutual conductance value of each tube can be obtained by setting the "Sensitivity" control according to a separate chart attached to the inside of the front cover. In addition, this instrument will also reveal gassy tubes, tubes with grid-to-cathode leakage, and tubes having contaminated grids. Tube shorts, between heater and cathode, grid and cathode, grid and screen, or grid and plate, will automatically light up a neon bulb. Another automatic feature of this instrument is its line voltage regulator circuit. This maintains test voltages constant over power line variations from 105 volts to 125 volts. An interesting feature of the Model 500 is the provision made for keeping the socket panel plate up-to-date. The designers of this instrument recognized that new tubes are appearing constantly and a tube tester must keep abreast of these changes if it is to retain its usefulness for any extended period of time. To meet this situation, a new overlay plate will be prepared whenever a significant number of new tubes has been developed. The instrument owner will then be able to obtain this plate for a nominal charge and use it to cover the original plate. The Model 500 "Dyna-Quik" tester is specifically designed to be taken into the house where a rapid check of all receiver tubes may be made. In this respect it will not only pinpoint tubes which are definitely bad, but a special life test will also reveal those tubes which are on their way to becoming defective. By calling the latter tubes to the set owner's attention, callbacks can be significantly reduced, Tele Test T-56 Checker Another rapid testing tube checker is the TeleTest T-56 instrument. This contains 60 sockets and is equipped to check a wide variety of receiving tubes as well as picture tubes and selenium rectifiers. In addition, continuity can be tested in circuits having resistance as high as 1 1/2 to 2 megohms. If continuity exists, a neon bulb will light up. If more than 2 megohms of resistance is present (and this includes an open circuit), the bulb will remain unlit. The manner in which the TeleTest Model T-56 is used for its main purpose of checking tubes is quite simple. All of the tubes which can be tested in this instrument are listed on a tube chart which is fastened to the inside of the top cover of the carrying case. The first column after the tube type contains the etter indicating the setting of the "Filament" switch. The second column contains the number of the proper test socket on the panel of the tester. The third column contains the number that indicates the section to be tested. The fourth column has the "Reference" number or meter reading for that tube type. If a tube has only one section, there will be only one section setting and one reference number. A tube can have as many as four sections. In the event that the tube has more than one section, there will be a separate section number for each section and a separate reference number. The reference number refers to the meter scale. This scale is divided from 0 to 100. In checking a tube, if the meter reads on or below the reference number for that tube, it can be considered faulty and should be replaced. For a tube to be considered good, the meter should read above the reference number. Just beneath the indicating meter there are three neon bulbs. Inter-element shorts automatically light one of these bulbs prior to the test of the tube or section of the tube. Heater-to-cathode shorts are revealed by the lighting of one of the other neon bulbs. The third bulb lights .up when a tube is gassy, or there is grid emission or there is less than the desired resistance between grid and cathode. (The latter is sometimes referred to as a high resistance grid short, which is obviously a misnomer, or as grid leakage.) Either of the foregoing tube testers may be used in the home (their primary purpose) or they may be used in the shop. In the latter place it has been suggested that customers be permitted to check their own tubes, when these are brought in. It has been found (surprisingly enough) that when a customer checks the tubes himself, he is more likely to replace all those showing up 'bad, Whatever the psychology behind this, the service technician benefits two ways. First, he sells more tubes. Second, he does not lose 20 to 30 minutes checking tubes.

Posted October 26, 2020 |

||