|

August 1967 Electronics World

Table

of Contents

Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

If

you are a collector of vintage high-end audio equipment, chances are you owned a

reel-to-reel tape player. I remember back in the 1970s that anybody wanting to call

himself an audiophile had better own a rack-mounted reel-to-reel player. Of course

the funny part is that many of those people could not afford to buy original recordings

on tape, so they would dub from an LP on a turntable or from a cassette or, gasp,

8-track tape. This article from the August 1967 edition of Electronics World

delves into the technical aspects of magnetic tape, daring to introduce such terms

as intrinsic cohesive force, residual induction, and flux - heavy stuff for the

layman. Of course, regurgitating such terms while

wowing (pun

intended) their friends with a rolling tape held to keep the subject off of whether

the music being played on a $1000 reel-to-reel player had been dubbed from a $75

cassette deck. If

you are a collector of vintage high-end audio equipment, chances are you owned a

reel-to-reel tape player. I remember back in the 1970s that anybody wanting to call

himself an audiophile had better own a rack-mounted reel-to-reel player. Of course

the funny part is that many of those people could not afford to buy original recordings

on tape, so they would dub from an LP on a turntable or from a cassette or, gasp,

8-track tape. This article from the August 1967 edition of Electronics World

delves into the technical aspects of magnetic tape, daring to introduce such terms

as intrinsic cohesive force, residual induction, and flux - heavy stuff for the

layman. Of course, regurgitating such terms while

wowing (pun

intended) their friends with a rolling tape held to keep the subject off of whether

the music being played on a $1000 reel-to-reel player had been dubbed from a $75

cassette deck.

Magnetic Properties of Tape

The tape user looks at magnetic tape in

terms of its electrical performance on the recorder, expecting a certain frequency

response or a specified signal-to-noise ratio. The tape maker must translate these

requirements into magnetic properties which, when present in the tape, will assure

the specified machine performance. Since magnetism is the operating principle in

tape recording, it follows that the magnetic properties determine the electrical

performance of the tape. The chemical and physical attributes have a very pronounced

effect on the magnetic behavior of the tape, but their main role is to assure the

best possible magnetic characteristics for a given purpose. The tape user looks at magnetic tape in

terms of its electrical performance on the recorder, expecting a certain frequency

response or a specified signal-to-noise ratio. The tape maker must translate these

requirements into magnetic properties which, when present in the tape, will assure

the specified machine performance. Since magnetism is the operating principle in

tape recording, it follows that the magnetic properties determine the electrical

performance of the tape. The chemical and physical attributes have a very pronounced

effect on the magnetic behavior of the tape, but their main role is to assure the

best possible magnetic characteristics for a given purpose.

Most tape makers design and predict the electrical performance of their products

by controlling the magnetic properties throughout the manufacturing process. This

control is exercised predominantly prior to the actual coating operation, because

after this point the tape is largely finished and little can be done to correct

any faults. The knowledge of the valid relationship between magnetic and electrical

properties is, therefore, of vital importance to the manufacturer, but it should

be of value to the user as well to enable him to utilize this medium more effectively.

It appears worthwhile to describe briefly some of these relationships, to help the

reader in forming a clearer picture as to what the tape manufacturer is doing and

what parameters he is manipulating to make the tape better. It must be understood,

however. that this coverage is necessarily incomplete and greatly simplified; it

is meant only to establish a few rules of thumb.

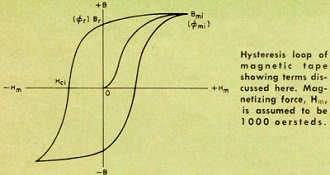

Hysteresis of Magnetic Tape

The figure shows a typical hysteresis loop of a magnetic tape. The symbols indicated

are the ones usually listed in technical data sheets and other tape literature and

are, therefore, quite appropriate to this discussion. Most data sheets specify the

magnetic characteristics at a fixed magnetizing force. Hm, of 1000 oersteds.

For all practical purposes, a force of 1000 oersteds is sufficient to saturate the

majority of magnetic tapes. By strict definition, however, saturation is not reached

until the tapes are subjected to several thousand oersteds. For this reason, the

symbols shown in the figure lock the sub-index "s" which would denote saturation.

For instance. Br (residual induction) is used here instead of Brs

(retentivity); Bmi (maximum intrinsic induction) is shown instead of

Bs (saturation induction). Many tape data sheets do not make this distinction

and employ the saturation symbols and terminology with the tacit assumption that

1000 oersteds is indeed Hs (magnetizing force high enough to produce

saturation). These side remarks may prove helpful in clearing up seeming inconsistencies

among various data sheets and specifications.

Intrinsic Coercive Force

The symbol on the abscissa of interest here is Hci (intrinsic coercive

force). Hci, by definition, measures the demagnetizing force that is

necessary to bring the induction to zero. It therefore indicates the tape's ability

to resist demagnetization whether intentional or accidental. A case of intentional

demagnetization is the erasure of a recording with a head or a bulk eraser, the

higher Hci requiring a higher erasing force for the some degree of signal

reduction. Accidental demagnetization does not refer to pushing the record button

by mistake, but to selferasure of short wavelengths by the self-demagnetizing action

of the recorded signal. Higher Hci tape, therefore. may be expected to

have reduced short wavelengths losses. i.e. better high-frequency response

In addition to defining the resistance to demagnetization or erasure Hci

also determines the tape's resistance to magnetization or recording. Accordingly.

a higher Hci tape, when compared to an otherwise identical tape but having

lower Hci, will require a higher bias and record current for equal output

and distortion.

Nearly all magnetic tapes utilizing gamma ferric iron oxide as the active ingredient

fall within the range from 230 to 330 oersteds, with 250-270 being most common (at

Hm of 1000 oersteds). Given the impetus by modern instrumentation and

computer tapes which put high-frequency response and resolution as the major requirements,

the industry is moving slowly but inexorably toward higher Hci tapes.

High coercive force tapes, 400 to 600 oersteds, are around the corner for the more

exotic tapes, but it will be some time before they are used in audio work.

Residual Induction and Flux

The second magnetic characteristic to be considered is Br (residual

induction or flux density) measured in gausses. Br is a calculated value

obtained from the expression, Br = Φr/A, where Φr is the residual

flux, measured in maxwells, and A is the tape cross-sectional area in cm2.

Cross-section is the product of tape width and coating thickness.

Φr is directly proportional to the tape width and thickness, at a

constant Br. To put it another way, the same Φr may be achieved

with half the thickness, but doubling the Br for the same width.

Φr determines the amount of magnetization remaining in the tape after

the magnetizing force has been removed. Φr thus establishes the magnitude

of the playback output. Br on the other hand, defines the coating thickness

necessary to achieve the required Φr.

In very general terms, the output at long wavelengths - within the limits of

the 6 dB per octave unequalized playback slope - will increase with Φr,

providing the record head is capable of biasing the entire thickness. An increase

of thickness and, consequently, of Φr, beyond this point will not raise

the output any further. A tape with a higher Br though would allow for

an increase of Φr with no change in thickness and thus result in an increased

output.

In short wavelength recording - starting beyond the peak on the unequalized playback

curve - the surface of the coating nearest to the head produces most of the output.

The contribution to the output of the layers farther away from the head diminish

with decreasing wavelengths. The short wavelength output therefore depends on the

Φr of the top layer of the coating. It is clear then that increasing

the Φr by a thicker coating is useless and will not improve the high-frequency

output. The solution is to raise the Φr within the active layer, which may be accomplished

only by a higher Br.

These examples illustrate that high Br is generally advantageous in

sound recording, especially if a full frequency spectrum is to be recorded at slow

speeds. Unlike Φr, however, which may be changed pretty much at will

simply by varying the coating thickness, Br is subject to more limitations.

Br is limited by the available induction of iron oxide, oxide concentration

in the coating, coating density, and magnetic losses. Present tapes run from about

700-1400 gausses, the most common ranging from 800-1100 gausses. Φr of

the present tape ranges from about 0.2 to 1.2 maxwells per 1/4-inch width, with

0.6 maxwell being typical.

The coating thickness range is from about 150 to 800 microinches, with about

450 microinches average. (Note, Φr must be expressed as so many maxwells

per given width, predominantly 1/4 inch. Otherwise, Φr is meaningless.)

Maximum Intrinsic Induction and Flux

Bmi (maximum intrinsic induction) and Φmi (maximum

intrinsic flux) have the same units and are derived in the same way as Br

or Φr. As the figure shows, they denote the maximum value of flux or

induction while the magnetizing force of 1000 oersteds is applied to the tape. This

property is an important control parameter for the tape manufacturer, but of little

use per se to the sound recordist. When compared with Br however, it

yields squareness is the result.

Squareness

Squareness, as it is commonly but not quite correctly called, is the ratio Br/Bmi

or the numerically equivalent Φr/Φmi. Since Bmi

is determined while the magnetizing force is applied, the demagnetizing losses are

zero. Br is determined at zero force where the demagnetizing losses are

maximum. The ratio of these two properties is thus a measure of the internal losses

in the coating. These may be caused by a variety of reasons including faulty dispersion,

poor quality or damaged oxide particles, wide distribution of particle shapes, insufficient

orientation, and other factors. Some tape manufacturers have special tests to determine

the exact cause of low squareness, but they cannot be discussed here. The range

of squareness in current tapes is from 0.63 to 0.82 (at 1000 oersteds) the typical

being about 0.76. Since the ideal squareness is 1, the 0.76 indicates a demagnetizing

loss of 24% resulting in a corresponding loss in Br. Values ranging from

0.85 to 0.93 have been achieved in laboratories.

Squareness is important not only because of its direct influence on Br

but even more so by its effect on output losses caused by self demagnetization by

the signal itself. This effect is closely related to the accidental demagnetization

mentioned previously in connection with Hci. These two parameters, squareness

and Hci, must be considered together as the interaction between them

can either offset or multiply the individual effects.

The matter of interrelation among the different properties is worthy of special

emphasis. These interrelations are often quite complex and could lead to wrong conclusions

if considered without sufficient data or without the necessary experience. Readers

are advised, therefore, to be cautious in making decisions about tape quality on

the sale basis of the magnetic properties as listed in tape data sheets. The rules

of thumb presented here are very useful but tell only part of the story.

Posted July 27, 2021

(updated from original post on 8/26/2011)

|

If

you are a collector of vintage high-end audio equipment, chances are you owned a

reel-to-reel tape player. I remember back in the 1970s that anybody wanting to call

himself an audiophile had better own a rack-mounted reel-to-reel player. Of course

the funny part is that many of those people could not afford to buy original recordings

on tape, so they would dub from an LP on a turntable or from a cassette or, gasp,

8-track tape. This article from the August 1967 edition of Electronics World

delves into the technical aspects of magnetic tape, daring to introduce such terms

as intrinsic cohesive force, residual induction, and flux - heavy stuff for the

layman. Of course, regurgitating such terms while

If

you are a collector of vintage high-end audio equipment, chances are you owned a

reel-to-reel tape player. I remember back in the 1970s that anybody wanting to call

himself an audiophile had better own a rack-mounted reel-to-reel player. Of course

the funny part is that many of those people could not afford to buy original recordings

on tape, so they would dub from an LP on a turntable or from a cassette or, gasp,

8-track tape. This article from the August 1967 edition of Electronics World

delves into the technical aspects of magnetic tape, daring to introduce such terms

as intrinsic cohesive force, residual induction, and flux - heavy stuff for the

layman. Of course, regurgitating such terms while