|

April 1969 Electronics World

Table of Contents

Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

Mechanical filters of the

type described in this 1969 Electronics World magazine article are yet another example

of the genius of some people. They are actually a form of electromechanical device

in that the applied electrical signals are first converted into mechanical signals,

followed by resonant mechanical elements that discriminate according to frequency,

and finally a conversion back to an electrical signal is made. It is fundamentally

the same principal as a crystal, SAW, or BAW filter, albeit each with distinctly

different methods and topologies. Mr. Donovan Southworth, of Collins Radio, presents

the basics of mechanical filters in this brief write-up. There is an excellent article

on mechanical

filters on Wikipedia.

Mechanical Filters

The author has experience in all phases of mechanical filter

research and development. He joined Collins in 1961 after receiving his BSEE degree

from Washington State University. His initial work was in the field of synthesis

and fabrication of crystal filter networks. Since 1963 he has participated in studies

of higher order vibration modes for extension of the mechanical filter operating

frequency range, and in the development of filter design by computer programs. He

was project engineer of the mechanical Minifiiter and is currently involved in the

design and fabrication of mechanical filter networks.

By Donovan A. Southworth / Collins Radio Company

Mechanical filters are not new, but new manufacturing techniques and new filter

configurations have made them "tops" in sophisticated transceivers.

Mechanical filters were conceived and designed to provide a unique combination

of high selectivity and stability in a compact package at a low cost. Many of these

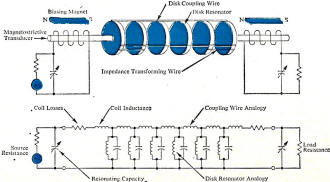

filters use a disk-wire construction (Fig. 1.) which has become popular in

our industry.

The disk-wire filter is a mechanically resonant device which receives an electrical

signal, converts this signal into mechanical vibrations, rejects unwanted frequencies

within the mechanical structure, and then converts the mechanical vibrations back

into electrical energy. The filter consists of three basic elements: input and output

transducers which convert electrical signals into mechanical vibrations and vice

versa; high-"Q" mechanically resonant metal disks; and coupling wires which acoustically

transmit energy between the disk resonators.

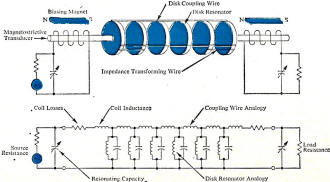

In Fig. 3, if an electrical signal is applied to the input coil, it produces

an alternating magnetic field that passes through the magnetostrictive transducer

attached to the end disk. The transducer, when magnetically biased and tuned to

vibrate at the impressed signal frequency, drives the first disk. The short coupling

wires connecting the disks drive the next disk, and so on until the signal reaches

the output transducer. The output transducer converts the mechanical vibrations

into an induced voltage across the output coil and creates an electrical output.

Engineers are busy in Europe and Japan, as well as in the United States, designing

mechanical filters and resonators. One popular i.f. filter design utilizes a wire-coupled

torsional rod. But much of the engineering activity involves units operating below

50 kHz, where physical configurations other than the disk-wire or rod-wire

arrangements are more suitable for production. In this frequency range, filters/resonators

utilize a tuning fork or flexure mode bar. The devices commercially available in

this range are often single resonator types rather than multiple-coupled resonators.

Disk-wire type filters are manufactured in the 60- to 600- kHz frequency

range with pass bandwidths ranging from 0.06% to 10% (see Fig. 2). The shape

factor (60 dB to 3 dB bandwidth ratio) is typically from 2:1 to 1.5:1 although in

certain critical applications where even better selectivity is required, shape factors

as low as 1.2:1 are being built. Frequency stability with temperature change can

be made equal to the stability of a DT-cut crystal. This is one of the most widely

used crystal cuts in the 200- to 500-kHz frequency range. Modern network design

techniques have resulted in passband response variation of less than 0.5 dB; and

insertion loss values as low as 2 dB can be realized, but a more typical value is

6 dB. Prices start around $7.00 and are related to performance requirements.

Some Uses

Mechanical filters were originally designed in the U.S. for use in single-sideband

radios. They contributed to the success of such radios in the early 1950's and are

still being used extensively in single-sideband equipment. The small size and weight

of a mechanical filter make it very desirable for use in equipment such as manpack

radios. These characteristics, in addition to high reliability, excellent frequency

stability with temperature, and good cut-off characteristics, combine to satisfy

the stringent requirements of military or commercial aircraft communications and

navigation equipment. Generally, mechanical filters should be considered for use

anywhere that high performance, small size, and reasonable cost are required.

Fig. 1 - Varying the coupling of a multi-element mechanical

filter changes its bandwidth. Bandwidths range from 350 Hz - 50 kHz.

Fig. 2 - Available percent bandwidth versus center frequency

for a typical filter unit.

Fig. 3 - An electrical analogy of a typical multi-element

mechanical filter. The mechanical vibration of the input transducer is coupled by

successive disks to the output magnetostrictive transducer where the vibration is

converted into electrical energy. The equivalent circuit is also shown.

Mechanical filters made in the U.S. employ two basic transducer types: a nickel-iron

alloy wire and a nickel-ferrite rod. The filters which use the nickel-iron wire

transducers are essentially self-terminated and have a relatively high insertion

loss. They may be driven from any source impedance greater than 50k ohms by parallel

tuning the transducer coil, or they may be driven from any impedance lower than

200 ohms by series-tuning the transducer coil. The same conditions apply for the

filter output. If the circuit designer finds it to his advantage, a combination

of series- and parallel-tuning capacitors may be used.

Filters using ferrite transducers have low insertion loss and are designed to

work with a specific terminating resistance. For standard filters (either wire or

ferrite transducer types), the terminating resistance can be modified using a transformer

or capacitor dividing network to match some other value of termination. For special

filter designs, the terminating resistance may be specified in the range from 50

to 100,000 ohms. Essentially, the value of resistance determines whether the filter

is parallel- or series-tuned. For low-impedance applications, such as conventional

transistor circuits, the filter is tuned to series resonance. For high-impedance

requirements - FET's, vacuum tubes, etc., parallel tuning is used.

All standard mechanical filters are designed with both input and output terminals

isolated from ground. This eliminates the need for isolation transformers in applications

using balanced loads. However, it is necessary to ground the filter case (either

a terminal or mounting studs are provided for the ground connection). In any case,

optimum selectivity is achieved when the coupling or "feed-through" between input

and output terminals is minimized. If proper care is exercised, 120-dB discrimination

is attainable.

Picking the Right Filter

Some of the characteristics to be considered when specifying a filter are: 1.

center frequency or carrier frequency; 2. required passband width; 3. selectivity

or skirt cut-off; 4. maximum passband ripple or response variation; 5. maximum insertion

loss; 6. source and load impedances; 7. operating temperature range; 8. other environmental

requirements, e.g., shock and vibration; 9. package configuration; 10. special requirements,

if any, such as particular phase shift or envelope delay requirements.

Confusion frequently exists when talking about "passband ripple." Passband ripple

is sometimes interpreted to mean the ratio, in dB, between the maximum and minimum

amplitude of immediately adjacent peaks and valleys, and does not define amplitudes

relative to other peaks and valleys in the passband. A more meaningful interpretation

is to use the term "response variation since it always describes the worst-case

condition. This term means the ratio in dB between the maximum amplitude and the

minimum amplitude occurring anywhere across the entire passband whether these points

are adjacent or not. It is important that the equipment designer realize how a particular

manufacturer defines this characteristic since it may affect the performance or

his equipment.

When specifying a filter, the circuit designer should remember that the more

stringent his requirements, the higher the cost of the filter. It is usually worthwhile

to analyze circuit performance so that the filter will not be "over-specified."

Conservative design is always good engineering practice, as long as the designer

recognizes that this might increase his costs.

The general outlook for the future of mechanical filters is excellent. New filter

configurations are being investigated which will result in further advances in the

state-of-the-art. For example, lattice configurations, which give the filter designer

another degree of freedom, are being utilized. Filters with built-in delay equalization

are being realized, resulting in characteristics that heretofore could be achieved

only with an expensive filter and a separate expensive equalizer. Piezoelectric

ceramic transducers are being used to give another design approach for filters with

requirements that were previously unobtainable. Techniques for achieving better

selectivity by means of bridged coupling wires have been developed and metallurgical

techniques are being expanded to give even better operating temperature characteristics.

In addition, advances in manufacturing processes have made it possible to miniaturize

and build highly selective filters in less than a 0.07-cubic-inch package.

Mechanical filters have far exceeded the original requirements for which they

were conceived. Future developments in mechanical filter technology will continue

to place emphasis on high quality and sophisticated filter requirements in minimum

size and at lowest cost.

References

Hathaway, J. C. and Babcock, D. F.: "Survey of Mechanical Filters and Their Applications,"

Proceedings of the IRE, January 1957

Borner, M.: "Progress in Electromechanical Filters;" The Radio and Electronic

Engineer, March 1965

Konno M., Kusakabe, C., and Tomikawa, Y.: "Electromechanical Filter Composed

of Transversely Vibrating Resonators for Low Frequencies," Jour. of Acoustical Society

of America, April 1967

Johnson, R.A. and Teske. R. J.: "A Mechanical Filter Having General Stopband

Characteristics," IEEE Transactions on Sonics and Ultrasonics, July 1966.

|