|

October 1960 Electronics World

Table of Contents Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

Capacitors come in a huge variety

of package configurations, chemical makeups, physical constructions and sizes, capacitance

values, and voltage and power handling abilities. Each has its own strengths and

weaknesses for a particular application. When capacitors are functioning properly,

life is great, but when one decides to fail either completely or partially, troubleshooting

the cause can be a real challenge. The best kind of electrical component failure

from a troubleshooting perspective is one where the component releases its life-giving

internal smoke and in the process leaving a clearly visible clue like a cracked

case or a nice black mark when none should be. Otherwise, the job can get interesting.

Being proficient at schematic reading and tracing waveforms through circuits is

a real benefit, but that option is not always available, as in the case of undocumented

equipment. In that situation, experience and intuition might be your only hope.

This article gives some pointers that can put another method or two in your collective

bag of tricks.

Wayward Capacitor Woes

By Allan F. Kinckiner

Fig. 1 - Sensitive capacitor leakage measurement.

Look out for "perfectly good" capacitors that pass all tests but produce strange

and confusing faults.

Every technician is confronted at one time or another by tubes that pass every

test on the very best tube checkers but simply will not work properly in certain

circuits, although a substituted tube will. After a number of such experiences,

the technician adopts the following credo: If a tube is suspected, don't rely on

a check-substitute.

Another electronic component that often presents the same baffling condition

of causing circuit malfunction while passing every test is our friend the capacitor.

A look at what tests these components are subjected to in the better capacitor analyzers

reveals the following: capacitance measurement (generally quite accurate) and leakage

(the amount of direct current the component will pass). In the latter check, a substantial

d.c. voltage is fed into one terminal of the component, which is in series with

a voltage-reading meter. Some analyzers use eye tubes or neon bulbs in place of

the meter.

A more efficient leakage test is to use a source of several hundred volts (depending

on the component's rating) applied to one terminal of the capacitor, which is series-connected

to a v.t.v.m., as in Fig. 1. Leakage resistance may then be determined from the

following relationship: Rc/Rm = Ec/Em;

where Rc is the leakage resistance of the capacitor, Rm the

input d.c. resistance of the v.t.v.m. (usually 11 megohms), Ec is the

voltage across the capacitor, and Em is the voltage read on the meter.

In the example shown, the meter reading (Em.) is .1 volt, which leaves

299.9 volts as Ec. Solving for Rc, we we have a leakage resistance

of almost 33,000 megohms. The leakage current, determined by Ohm's Law, would come

to less than a hundredth of a microampere. Insignificant as these leakage figures

seem, there are circuits in which capacitor replacement would be warranted.

The advantages of checking leakage in this way are twofold. First, the sensitivity

is greater than in the test provided by most analyzers. In the second place, leakage

is more easily read. A man could get eyestrain trying to judge the opening or closing

of an eye tube or the lighting of a neon lamp. However, just as the tube checker

should be neither condemned nor scrapped because it doesn't bat one thousand, the

capacitor analyzer should not be demoted for its less-than-perfect score on the

leakage test.

Fig. 2. - Preamp in which noise was generated by a "good" ceramic

capacitor.

It is true that the substitution of a suspected capacitor is not so easily accomplished

as that of a tube. Yet this will often be the quickest path to a repair. However,

the substitution should only be considered after thorough circuit testing has left

the capacitor as the prime suspect, although on circumstantial evidence. The capacitor

fault may be so elusive that it will not always be possible to, determine exactly

what defect has occurred, although malfunction disappears when a substitution is

made. Following are several accounts of skirmishes with capacitors, to prove the

points made.

Before going into the case histories, we should like to point out another parallel

between tubes and capacitors. The baffling defects are most likely to occur in more

critical electronic circuits, such as low-level amplifiers, discriminating or limiting

networks (such as the sync stages), sine and other waveform generators (such as

TV deflection generators), and in other pulse-handling or pulse-forming circuits.

The Sizzling Ceramic

A V-M model 711 tape recorder came in for service with the complaint of being

noisy. Inspection revealed that, with no tape threaded on and with the "play" button

depressed, a constant sizzling noise could be heard. The latter could be attenuated

by adjusting the volume control, indicating that the trouble was in a preceding

stage (or perhaps in a later stage, but was being detected by the sensitive preamplifier).

A scope check quickly eliminated the alternate possibility in this instance.

The preamplifier consisted of a 12A-X7 with the triodes in cascade (see Fig.

2.) Further troubleshooting revealed that grounding the second grid killed the noise,

but grounding the first grid had no effect. The sizzling noise sounded precisely

like a noisy resistor, so the resistors were substituted after resistance and voltage

checks in the order numbered, but without any result.

Capacitor Cx was disconnected at the second grid and checked with

an analyzer, which passed it as being faultless. Cx was also checked

as per the technique discussed in connection with Fig, 1; not the slightest leakage

was indicated. Since every other component in the circuit had been substituted,

Cx was now temporarily replaced with a tacked-in unit, and dawg-gone

if that didn't cure the trouble.

This capacitor, a black .01-μf. disc ceramic, subjected to all types of further

testing on our brand X capacitor analyzer, was also checked on a fellow service

technician's brand Y analyzer. It passed without even the slightest indication of

fault.

Shifting Height

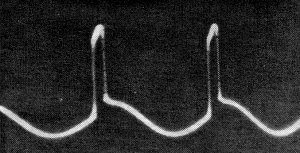

Fig. 3. - Low (A, top) and proper (B, bottom) sinewave height

in Synchroguide waveform.

A TV set came in with the complaint that raster height was insufficient, with

the compression occurring on the bottom. The condition occurred only after the receiver

had been operating an hour or more, and would get progressively worse. After the

saw-tooth forming capacitor in the vertical circuit had been replaced, the bottom

of the raster was easily stretched out to fill the bottom of the CRT screen with

normal linearity. Furthermore, the raster remained constant in vertical size, without

needing later readjustment.

The capacitors that produce the not uncommon defect noted here are generally

of the waxed paper type. Their capacitance may tend to increase as their temperature

goes up. While a capacitor analyzer is quite capable of indicating an increase in

capacitance, it can do so only if the suspected component is heated to the temperature

at which it works in the receiver. Thus, tacking in a replacement is the quickest

way to make a satisfactory check.

Sneaky Plastics

The horizontal Synchroguide circuit is one of those where capacitors can really

raise havoc. For example:

The fellow service technician previously referred to as the owner of the brand

Y analyzer sought help on a tough dog. It was an RCA KCS34B that would not hold

horizontal sync for more than twenty minutes. In answer to questioning, he insisted

that he had disconnected and tested all the capacitors in the circuit and that all

read up to par on his analyzer. Knowing him to be a thorough technician who normally

makes the necessary resistance, voltage, and scope checks when he has trouble, we

advised him to tack-solder capacitor substitutions.

About one hour later he phoned with the information that, "after replacing the

.002 μf. that feeds the sync and sampling pulses to the grid of the a.f.c. triode

(C1 in Fig. 5), the trouble was corrected." While he was happy that he

had repaired the set, he was also extremely unhappy because his expensive analyzer

would not indicate anything wrong with the replaced unit. The .002-μf. unit was

one of those black, plastic-encased capacitors.

In line with this experience involving Synchroguides, one set, an RCA KCS84F,

operated relatively normally except that the horizontal sync was critical. It was

noticed during troubleshooting that the frequency slug of the oscillator transformer

adjusted at an extremely withdrawn position. Component and voltage-checking tests

revealed nothing, so the various frequency-determining capacitors were temporarily

replaced. When C2 in Fig. 5 was replaced, not only did the frequency

slug adjust to a more orthodox position, but the horizontal saw-tooth waveform increased

from 130 to over 160 volts, peak-to-peak, as a scope check showed. As a result other

improvements occurred; the width increased, as did the high voltage, with improved

focusing.

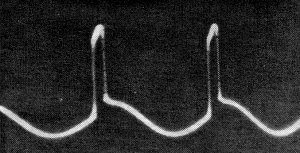

Fig. 4. - Low (A. top) and proper (B, bottom) sine-wave height

in multivibrator waveform.

C2 was also a black, plastic-encased tubular; it too passed all tests,

including leakage, and its measured capacitance was within ten percent of nominal

value although it was only rated at twenty percent. We are not exactly sure what

the elusive fault is that occurs in units of this type, but suspect that the pulsed

nature of the voltage to which they are subjected causes them to react erratically

in a way that does not show up on static tests.

Watch That "Q"

On to case 4: The stabilizing network in the Synchroguide circuit is a tank that

generates a sine wave at approximately the horizontal sync frequency. This plays

an important role in maintaining synchronization in the presence of random pulses

that might otherwise trigger the oscillator falsely. The network consists of an

adjustable coil shunted by a capacitor.

In Fig. 5, this network consists of C3 shunted by Lp, with

the latter being known as the phasing coil. Stabilizing efficiency is affected by

the over-all "Q" of the tank, which is affected by the "Q" of C3 specifically.

This factor may decrease over a period of time, reducing sine-wave amplitude.

Analyzers will not indicate this lowered "Q" factor, but it can be determined

with the scope. The waveform of Fig. 3A was noted at point C of a Synchroguide used

in a '53 Philco. Note that, while the phasing coil is adjusted properly, the sine-wave

amplitude is about 15 percent of the composite waveform's total amplitude. The waveform

of Fig. 3B was noted at the same point after C3 was changed. Note now

that the sine-wave amplitude is nearly 25 percent of the composite amplitude. This

change improved horizontal synchronization in this particular receiver considerably.

In multivibrator-type horizontal oscillators, the stabilizing tank again consists

of an adjustable coil (usually called the ringing coil) shunted by a capacitor.

The coil's action parallels that of the phasing coil in that it generates a sine

wave each time the oscillator plate switches on to draw current. The tank is invariably

in series with a resistor in the plate lead of the multi vibrator's controlling

(first) triode. The stabilizing efficiency of this network is similar to that of

the one in Fig. 5, and similar problems may occur.

Fig. 5. - Synchroguide oscillator with sinewave generating tank

(Lp and C3).

The relative "Q" factor of the tank in these circuits can also be determined

with the scope. Fig. 4A was taken at the plate of the first triode of a horizontal

multivibrator in a Motorola. Note that the amplitude of the sine wave is about 30

percent of the composite waveform's amplitude. Fig. 4B was taken at the same point

after the tank's capacitor was changed. Now the sine wave scopes better than 50

percent of the total waveform height. The replacement cleared up a complaint that

setting of the horizontal hold control was too critical.

The ratios given here for sine-wave amplitude to overall waveform height are

those most often used in original design for Synchroguide and multivibrator circuits,

although they are not universal. In general, where marginal horizontal-hold is the

problem and no other defects exist, approximating these ratios will produce enough

improvement to satisfy an unhappy customer.

The change in the capacitor, over a period of time, that produces this reduction

in sine-wave amplitude sheds light on the tendency of older sets to develop more

critical-sync.

Capacitor Or Rectifier?

A Philco TV about nine years old was benched for drifting vertical lock. The

hold control had to be readjusted every ten minutes until it reached the end of

its rotation, after which rolling could not be stopped. Trouble of this nature is

due to gradual changes in such frequency-determining oscillator components as resistors

(including the control), the blocking oscillator transformer, and, of course, the

coupling and timing capacitors. In this case, replacing a capacitor corrected the

trouble.

Suspected of leakage, the capacitor had been checked on an analyzer but no leakage

had been found. When it was checked again after the replacement had worked, there

was considerable leakage. Further checking showed that, when the capacitor was connected

to the tester in one way, there was still no leakage. However, when the capacitor

leads were reversed, leakage was clearly indicated! Evidently the component had

begun to act like a semiconductor, passing current in one direction only. It was

weird but it happened. The unit was a .01-μf. capacitor encased in plastic.

An Eccentric Electrolytic

Fig. 6. - The pointer indicates stain on capacitor case from

electrolyte leakage.

The villain in case 6, unlike the smaller units involved with the other histories

noted so far, was the big brother of the capacitor family, an electrolytic. A Sylvania

TV (Model 540) came in with the complaint that it was erratically blowing a 2.5-ampere

fuse. One fuse might last several days; but the next might only survive for one

hour.

In a bench check, line current was metered at about 1.5 amperes. Receiver operation

was entirely normal, with good picture and sound. Instrument checks revealed no

unusual conditions. However a visual check showed a suspicious chemical staining

at the metal band used to mount a 150-μf., 200-volt electrolytic filter to the

chassis. Unfastening the metal band by removing the self-tapping screw that held

it to the chassis caused the line current to fall to about 1 ampere.

Fig. 6 shows the staining on the cardboard case of this unit, with the metal

band removed to render the symptom more visible. This type of electrolyte leak-through

on cardboard-cased units was more common in prewar radios, where it often led to

puzzling hum problems. Service technicians can be grateful that the difficulty doesn't

arise so often these days, but they should keep in mind the fact that it can occur.

One end of this capacitor was connected directly to one side of the a.c. line in

a voltage doubler using two selenium rectifiers, which is why the leakage blew fuses.

However, an analyzer would not have indicated abnormal leakage.

Thus we close the file on wayward capacitors. In each of the cases described

here, the defects were of the kind that would escape detection with capacitor analyzers

or other direct instrument checks. In each, secondary evidence was the only indication

that the capacitor might be at fault. In closing, a few words of commendation might

be said for that old standby, the oscilloscope. As in several instances recounted

here, its role in revealing the secondary conditions that lead to apprehension of

guilty capacitors with off-beat defects is important.

Posted August 26, 2019

(updated from original post on 3/25/2014)

|