|

December 1954 Popular Electronics

Table

of Contents Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

Great minds think alike,

as the old saying goes. Back in 2021, my 1970s-era

General Electric Model 7-4305C

roll-down number clock-radio began making a high pitch grinding noise. It is

powered by a small, pancake AC synchronous motor. After looking on eBay for a

replacement motor, I discovered that they were commonly selling for $20-$50,

which is more than I paid for the radio. On a whim, I decided to try drilling a

small hole in the top of the motor case and injecting a couple drops of 3-in-1

motor oil (there was no way to safely open the case. The motor body was rotated

a few times to distribute the oil inside. I did not cover the hole since it was

purposely drilled in the top. When I plugged it back in, the noise was gone, and

to date has not returned. To my amazement, when perusing my hard copy of the

December 1954 issue of Popular Electronics magazine a few days ago, I ran across

this "How to Repair Your Electric Clock" article! The author did exactly the

same thing I did, except he covered the hole he made. I couldn't believe it. I

swear to you I had not seen this method before applying it to my noisy motor.

How to Repair Your Electric Clock

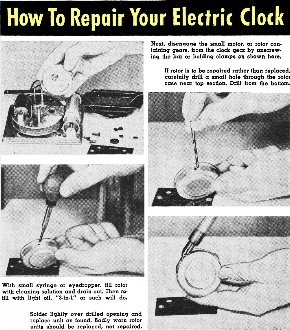

After disconnecting the line plug from the wall outlet. loosen the screws and

remove the clock assembly as shown. This is the first step in effecting clock repairs. After disconnecting the line plug from the wall outlet. loosen the screws and

remove the clock assembly as shown. This is the first step in effecting clock repairs.

Next, disengage the small motor, or rotor containing gears, from the clock gear

by unscrewing the bar or holding clamps as shown here.

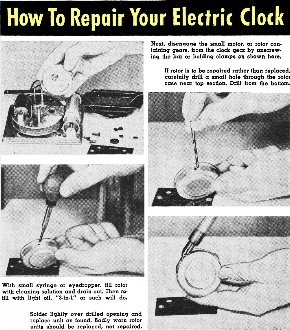

If rotor is to be repaired rather than replaced, carefully drill a small hole

through the rotor case near top section. Drill from the bottom.

With small syringe or eyedropper, fill rotor with cleaning solution and drain

out. Then refill with light oil. "3-in-1" or such will do.

Solder lightly over drilled opening and replace unit as found. Badly worn rotor

units should be replaced, not repaired.

Posted October 16, 2023

|