|

August 1965 Popular Electronics

Table of Contents Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

Restoring and/or upgrading

vintage radio receivers is still a very popular pastime for hobbyists, and for that

matter for some professional servicemen who preform maintenance on established equipment

installations. Three of the most significant changes that can be made to older receivers

to improve sensitivity are to clean up the power supply DC output, replace noisy

components like vacuum tubes and leaky capacitors, and tune / modify / replace RF

and IF filters. This 1965 Popular Electronics magazine article discusses

a method of replacing a stock LC filter with a high selectivity mechanical filter.

The nice thing about an analog receiver is that narrowband, steep-skirt filters

can be substituted without concern for group delay at the band edges that can (and

will) wreak havoc on digital signals.

Super Selectivity for Your Receiver

Mechanical filter sharpens bandwidth for

optimum reception of AM, CW, and SSB.

By Charles Caringella W6NJV

If your receiver or transceiver employs a 455-kc. Lf. strip, sharp selectivity

can be achieved by substituting a recently introduced mechanical filter (Lafayette

99 K 0123) for the first i.f. transformer to help you cope with today's crowded

radio bands. Several important advantages make this installation highly desirable.

Steep skirt selectivity makes it possible to overcome the masking effects of

strong or local signals as little as 5 kc. away. Once the filter is installed, it

doesn't need to be adjusted while the receiver is in operation. No objectionable

effects such as ringing or hollow sounds commonly associated with crystal filters

are present. The filter can be installed in most vacuum-tube-type amateur, commercial,

or CB equipment. Finally, it works well in AM, CW, and SSB receivers.

How It Works

The mechanical filter is basically an electromechanical

device. It consists of an input transducer, a resonant mechanical section having

several metal discs, and an output transducers, as shown above. Both transducers

are crystal types. An electrical signal applied to the input transducer is converted

into mechanical vibrations which travel through the resonant mechanical section

to the output transducer, where they are reconverted to electrical signals.

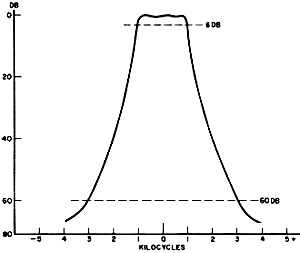

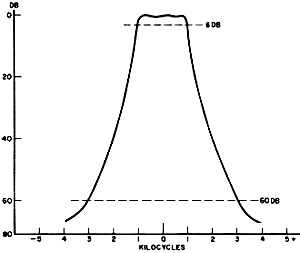

Fig. 1 - Bandwidth of 2 kc. at 6 db expands slowly to 6

kc. at 60 db. Steep skirt characteristic makes it possible to separate closely spaced

stations.

Fig. 2 - Typical receiver first i.f. stage before modification.

Internal circuitry of transformer can be ignored. However, the frequency of the

mechanical filter should be the same as the transformer to be replaced.

Fig. 3 - In addition to the mechanical filter, only two

capacitors and two resistors are added (within the dotted lines). Once the filter

is installed and the remaining i.f. transformers have been peaked, no further adjustments

need be made.

Fig. 4 - Mechanical filter and added components are grouped

together into a subassembly and mounted in the same manner as the original i.f.

transformer.

Fig. 5 - Bottom view of receiver before the first i.f. transformer

(T1 ) is removed. It is not necessary to disturb any other part of the receiver.

The selectivity characteristics of the filter are determined by the resonant

metal discs. Each disc is carefully machined to extremely close tolerances to make

it vibrate at a desired frequency, such as 455 kc. The discs are made of a ferro-nickel

chromium alloy for extreme hardness and resistance to corrosion. Each is supported

by - and coupled to the others with - a thin rod. The rod runs the entire length

of the filter, and is attached to the transducer at each end. Only those signals

within the filter's passband can get through.

Nominal bandpass characteristics of the filter used in this project are shown

in Fig. 1. At 6 db down on the response curve, the bandwidth is approximately

2 kc.; and at 60 db down, the bandwidth is approximately 6 kc.

It is natural for mechanically resonant elements, such as metal discs, to have

multiple resonances which allow spurious transmissions through the filter at frequencies

other than those in the primary passband. By employing conventional type i.f. transformers

at the input and output ends of the filter, these spurious signals are attenuated.

Signal frequencies of plus or minus 20 kc. from the i.f. (435 kc. and 475 kc.) are

cut by a minimum of 40 db. Frequencies above 475 kc. and below 435 kc. are far enough

away from the rest of the receiver's passband to be blocked, and thus be of no consequence.

Input and output impedance is 10,000 ohms. Capacitive coupling is required to

prevent B+ on the input side from getting to the output side, which is in the grid

circuit of the next stage, and to prevent B+ from shorting to ground. In order to

minimize the number of connections to the filter, the bottom leads of the windings

in both transformers are already connected to the ground foil on the filter's printed

circuit board. Only three connections are needed: plate, grid, and ground.

Fig. 6 - After the first i.f. transformer is removed, the

mechanical filter subassembly is installed, and held in place by two screws. The

board should be made small enough to pass through chassis opening.

Construction

The only parts you will need, in addition to the

mechanical filter, are two 10,000-ohm, 1/2-watt resistors, CR1 and R2), two 0.001-μf.

ceramic disc capacitors (C1 and C2), a 1" x 1" piece of Vectorbord or other suitable

material, six push-in terminals, and an L-shaped mounting bracket.

Except for the removal of the first i.f. transformer, all components and connections

in your receiver or transceiver remain the same. A typical circuit before modifications

is shown in Fig. 2. Variations in component values or in i.f. transformer design

in different receivers are not critical and will not adversely affect the installation

of the filter. Figure 3 shows the same portion of the receiver after the filter

has been installed.

The actual filter and additional components are mounted on a subassembly as shown

in Fig. 4. While it is not necessary to shield the filter - its components

are already housed in metal cans which have been grounded to the printed circuit

board - it is necessary to have a good ground connection between the board and the

receiver's chassis.

Fig. 7 - Above-the-chassis view of mechanical filter mounted

in place of T1. Insertion loss is on the order of 1.5 to 3 db.

The one-inch-square piece of Vectorbord is bolted to the bottom of the L-shaped

bracket. Resistors R1 and R2 and capacitors C1 and C2 are mounted on the board.

The push-in terminals serve to hold the components and the connections to the receiver.

Before and after photos show how the subassembly is mounted on the chassis. Check

to see that the board fits in the chassis opening, to fully seat the bracket.

Alignment

Generally, once the filter assembly has been installed,

no further alignment is necessary. However, you might try to peak the remaining

i.f. transformers in the receiver. Just in case the two transformers on the filter

have been diddled with, they too should be aligned for maximum output at the designated

intermediate frequency.

|