|

October 1972 Popular Electronics

Table of Contents Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

Every time I see

something about "transparent anything" that formerly was know only in an opaque

form, I think about the Star Trek "The Voyage

Home" movie (click on the link if you don't know what I mean). This

transparent ceramic material was a real breakthrough in optics technology in its

day due to the ability to control its degree of transparency or opacity with an

electric field. It would even retain its state with the electric field removed

so use as a data or even image storage device was possible. An ability to be quickly

switched (at up to a 10 MHz rate) held promise for it as a laser or other light source modulator

or even as a high speed facsimile (fax) system. It seems sort of like a solid

version of a liquid crystal display (LCD).

Lots of unique optics terms appear in this article, so I provided hyperlinks to

them for you.

Transparent Ceramics for Electro-Optics

New Ceramic Material Can Be Used to Control

Light New Ceramic Material Can Be Used to Control

Light

By Nigel S. Hey

Sandia Laboratories

Electro-Optical devices have been in use for quite a number of years, from Edison's

first incandescent light bulb to modern light-emitting diodes and research dye lasers.

Simply by closing a switch, these devices operated exactly as they were designed

to. However, in the attempt to modify the light after these devices are turned on,

problems begin to appear.

To solve the problems of light processing, Sandia Laboratories in Albuquerque,

New Mexico, has developed a new ceramic device which offers an alternative to traditional

Kerr and Pockels cells and other mechanical contrivances. The new ceramic is similar

to that used as the piezoelectric transducer in phonograph pickups. The big difference

is that the new ceramic - hot-pressed and doped with lanthanum, a metallic rare-earth

element - is transparent.

When sandwiched between crossed polarizers, the lanthanum-modified

lead zirconate-lead

titanate (PLZT) ceramic acts as a variable color filter or transmits light intensity

in response to an applied voltage. Used in a "scattering" mode, it displays black

and white images without the need for polarizers. Most important, PLZT has a built-in

memory.

Positive image stored in a ceramic electro-optic device. Plate

is 1 in. in diameter and is 0.0123 in. thick.

At least a minor revolution in electro-optic technology is promised by PLZT.

The ceramic can be used to modulate lasers for communication purposes; extract colors

from white light; store information in binary or decimal form; turn on and off light

beams; and store and display images. Variations of PLZT are suited to special applications

like high-contrast shutters or memories which retain stored information until erased.

How It Works

Let us take a microscopic look at PLZT. The material consists of randomly spaced

PLZT "crystallites," in which each unit cell is arranged like a cube with lead and

lanthanum ions at the corners, oxygen ions in the center of each face, and a titanium

or zirconium ion in the center of the cube.

In this configuration, both the unit cell and the crystallite are electrically

neutral. But in "slim loop" PLZT, the central titanium or zirconium ion is displaced

toward one of the oxygen ions when an electric field is applied. The unit cell distorts

into a tetragon and becomes an electric dipole. Clusters of unit cells align in

the same direction to form a domain dipole.

Increasing the electric field increases both the magnitude and alignment of the

domain dipoles. When the electric field is removed, the domain dipoles disappear

and the ceramic returns to its electrically and optically isotropic state.

In ferroelectric or "wide loop" PLZT, the unit cell is spontaneously distorted,

causing domain dipoles to exist with no applied electric field. When an electric

field is applied, it causes domains favorably aligned with respect to the field

to grow at the expense of others and produces increased domain alignment.

Controllable dipole alignment is the basis of PLZT's remarkable versatility.

This alignment determines whether or not the material is

birefringent (high or low

double refraction) and the magnitude of the birefringence. In another Mode of operation,

dipole alignment controls the ceramic's light-scattering properties.

Birefringence has the effect of changing the polarization of plane-polarized

light. By controlling birefringence, one can also control the amount or color of

light penetrating a polarized filter. Hence, PLZT can be said to be a solid-state

analog of the Kerr cell which exhibits a quadratic electro-optical effect. Alternatively,

using a different chemical mixture, PLZT exhibits a linear electro-optical effect

similar to a Pockels cell.

Unlike the Kerr cell. PLZT is solid-state and compact. It is less expensive to

make and has a much larger electro-optical effect than does potassium dihydrogen

phosphate (KDP) and

lithium niobate crystals commonly used in Pockets cells. For

the same applied voltage, 12 times the effect of KDP is produced by one composition

of PLZT.

Electro-Optical Memory

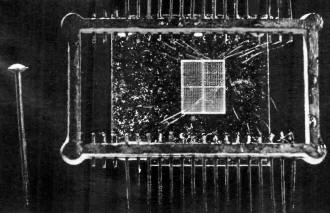

These variously shaped electro -optic ceramic pieces, made by

new process, are very transparent and homogeneous.

Prototype of ceramic memory element can store 5120 bits/sq.in.

Straight pin at left.

The one feature of PLZT that is unique is its electro-optical memory. When the

polarizing electric field is removed from "wide loop" PLZT, the domain dipoles do

not return to a random orientation. The ceramic remains birefringent and stays this

way until changed by electrically reorienting the dipoles. The dipoles can be returned

to a random orientation by raising the temperature of the PLZT to its Curie point.

In PLZT materials; the applied field-versus-birefringence plot follows a hysteresis

curve. Typically, memory-type PLZT exhibits a certain maximum retardation (saturation)

while the field is applied. When the field is removed, tire material relaxes into

a remanent (residual) state with a lesser birefringence. Subsequent electric field

pulses can be used to switch the ceramic into other

remanent states.

Device Applications

Many device applications present themselves when one considers the effect from

a relatively simple device consisting of an electroded ceramic slice sandwiched

between crossed polarizers. These include:

Memory material - light gates and shutters; optical memories which can he read

without photocell arrays; controlled-persistence displays and electrically controlled

spectral filters. For color effects, back lighting with plane-polarized light is

used. Each frequency component of white light is affected by birefringence. By applying

a specific voltage to the material, one color can he made to dominate as light penetrates

the analyzer. Monochromatic light is used to achieve "amplitude modulation."

Pockets - effect material-linear light modulation and momentary light shutters.

This material could be useful in modulating laser beams at frequencies up to approximately

10 MHz.

Kerr-effect material - quadratic light modulators and light shutters. This is

an extremely promising material since it is para-electric at room temperature and,

thus, optically isotropic. Virtually no light passes through the crossed

polarizers

of the device. When a field is applied, however, the crystallites distort and the

ceramic becomes birefringent. When the field is removed, the material immediately

relaxes to a para-electric state.

Longitudinal-Mode Ceramic

So far, devices in which an electric field is applied perpendicular to the direction

of light propagation (transverse mode) have been discussed. But one major development

has been pioneered at Sandia in which the field and light are applied in the same

direction (longitudinal mode). The new device is called

Cerampic.

In Cerampic, no birefringence is involved. The device works entirely by scattering

light. Dark areas of the image scatter more light away from the viewing plane than

do light areas. Non-image forming scattered light is then removed from the projected

light beam with a contrast-enhancing pinhole aperture.

To make Cerampic, one side of a PLZT ceramic slice is coated with photoconductive

polyvinyl carbazole (PVK). The device is then coated on both sides with transparent

electrodes.

High-resolution images (up to 1000 line pairs/inch) are stored in this device

by illuminating it with light through a photographic negative or with a scanning

light beam while applying voltage to the electrodes. Light passing through the negative

penetrates the transparent electrode and enters the PVK, decreasing electrical resistivity

anti allowing current to pass through the ceramic to the second transparent electrode.

In this manner, the relative opacity (or scattering capability) of innumerable points

on the ceramic plate is altered so that the device transmits various shades of gray

in the form of an image. The image has memory, is erasable, and can be viewed directly

or projected like a 35-mm slide.

A variety of potential uses is possible with Cerampic. Most promising is the

generation of images from signals received by telephone or radio. These images could

be generated in a few seconds or, conceivably, at rates of up to 15,000 lines/second.

Cerampic is being considered for use in optical information storage and processing

systems. The new scattering effect may also prove useful in devices such as shutters,

optical memories, and page composers for holographic memories.

Many companies are now working on devices that use PLZT as the basic working

medium. Since the material was developed by Sandia Laboratories under a prime Atomic

Energy Commission contract, the basic work is covered by patents held by the U.S.

Government. This means that private companies may be licensed to develop and use

the material on a no-royalty, revocable. nonexclusive basis.

Posted October 1, 2019

|