|

November 1966 QST

Table of Contents Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

QST, published December 1915 - present (visit ARRL

for info). All copyrights hereby acknowledged.

|

Author Pappenfus presents in this article

an alternative antenna for people operating at long wavelengths who do not particularly

want or are prohibited from having a Yagi or similar structure. At 80 meters, for

instance, a Yagi is only a little smaller than a football field - or so it seems.

The sight of such a structure towering over a neighborhood house is to a Ham what

the face of an ugly baby is to its mamma (something only a mother could love, per

the old yarn). A conical monopole antenna may be a reasonable compromise. The conical

monopole antenna is a base-fed vertical antenna having an omni-directional pattern

in azimuth but with an elevation pattern that keeps most of the energy down close

to the horizon, where it belongs for long-distance transmission.

The Conical Monopole Antenna: Four-to-One Frequency Coverage with

a Vertical

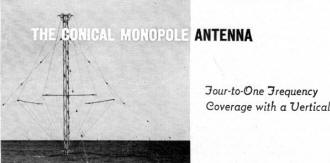

Commercial version of the conical monopole

used by the U.S. Navy and other government services. Commercial version of the conical monopole

used by the U.S. Navy and other government services.

By E. W. Pappenfus,* WB6LOH

It is important to concentrate your transmitter power into the proper beam if

you wish to deliver the best signal to the other fellow's receiving antenna. This

has logically led to the popularity of the Yagi beam antenna on the higher-frequency

amateur bands. A beam antenna for the 80-meter band should have a 140-foot reflector

and a 77-foot boom on a 250-foot tower. This makes the beam antenna impractical

for the 80-meter band, and even for 40-meter operation a full-size Yagi is a forbidding

structure to the neighbor's narrow-minded view - even a well-trained XYL might view

such a monster beam with alarm. There is no easy solution to the need for a good

DX antenna at low frequency, but the conical monopole antenna may be of interest

to the more eager radio amateur as a more practical solution. The conical monopole

antenna is a base-fed vertical antenna that has an omni-directional pattern in azimuth

but with an elevation (vertical plane) pattern that keeps most of the energy down

close to the horizon, where it belongs for long-distance transmission. This is important

as will be shown in the following table, giving the one-hop distances for an assumed

radio ray at various angles above the horizon.

News releases on the new WWV mention the use

of "conical monopole" antennas, and the same antenna has been seen at many military

installations. While the antenna is possibly a bit "rich" for the blood of most

hams, it is still interesting to know how it is constructed. The antenna was developed

and is sold by Granger Associates. News releases on the new WWV mention the use

of "conical monopole" antennas, and the same antenna has been seen at many military

installations. While the antenna is possibly a bit "rich" for the blood of most

hams, it is still interesting to know how it is constructed. The antenna was developed

and is sold by Granger Associates.

Fig. 1 - (A) Top view of the conical monopole antenna for

3.5 through 14 Mc. (B) Side view of conical monopole at section A-A. Note that grounding

stubs, b, connect to short radial wires, a. Wires c run up the sides of the supporting

pole.

Fig. 2 - (A) Top view of the antenna top hat. The steel

plate is held to the 2 X 4 spokes by wood screws. (B) Side view through section

B-B.

The above distances are based upon an assumed height of the virtual reflection

point in the ionosphere at 180 miles. It is evident from the table that it is important

to concentrate the radiated energy from the transmitter at low angles. Even when

two-hop transmission paths are assumed, the maximum of the elevation plane beam

should be held down "near the deck." For a path between New York and London, it

is desirable to radiate most of the energy below 8 degrees for a good two-hop path.

The Handbook1 shows that both horizontal dipoles and beams should be

about one wavelength above ground for low-angle radiation, and even with this height,

the maximum radiation is at 15 degrees with essentially zero right along the earth.

The above discussion of vertical plane patterns shows why a vertical antenna may

frequently out-perform a horizontal beam antenna. Another important consideration

of Yagi and dipole antennas is their very narrow-band characteristic. It is usually

hard to cover even one amateur band effectively without high v.s.w.r. using these

antennas.

The Conical Monopole

How would you like a good low-angle antenna that would cover not just one, but

three bands and that is only about 0.17 wavelength high? The conical monopole is

such an antenna. It is big compared with a dipole but then it is unfair to compare

a sailboat with an ocean liner, since the performance is much improved with the

big one. The conical monopole antenna consists of two hexagonal cones joined at

the bases. The lower cone, including an impedance-matching stub to improve the impedance

over the operating frequency range, is fed from the 50-ohm transmission line. To

simplify construction, the cones are simulated with wire elements to form a cage.

In commercial versions, the central tower, supporting the cages, is a metal tower

connected to ground, but the antenna described here uses a telephone pole with six

wires running down the pole connecting to the ground system. A pole is used because

no guying is needed and an old pole may be easier to find than a metal tower. Thus,

the antenna is at d.c. ground and this protects the station from lightning damage.

Fig. 1 shows the overall dimensions for a conical monopole antenna that

will cover the 80-, 40-, and 20-meter bands with a v.s.w.r, of less than 2.5 to

1. Unfortunately, the best impedance match to 50 ohms is in the range of 10 to 12

Mc., which is of no interest to the ham. The base of the cones is 31 feet across

the diagonal. The antenna is supported by a telephone pole about 48 feet long (five

feet of it in the ground) so no guying is needed. A guyed metal tower or wood -4

X 4 could be used if desired. The top cone is made up of 12 wires, 2 at each corner.

The bottom cone has 3 additional wires added to each face of the cone to better

simulate a solid cone. The sectional view of Fig. 1 shows the outside wires,

two of the six radial wires a, grounding stubs b, and pole wires c. The radial wires

and grounding shunt wires make up a shorting stub connected across the transmission

line that feeds the outside cage at the bottom of the lower cone. A ground radial

system consisting of 60 ground radials 62 feet long connects to the sheath of the

transmission line, to the six matching stub down-leads and the six wires running

down the pole.

Details

A small flat-top (see Fig. 2) at the top of the upper cone is supported

by 2 X 4s screwed to the pole with lag screws. A galvanized steel 16-gauge plate

at the top stabilizes the top hat and provides an easy termination for the cage

wires and the pole wires. All antenna wire is 10-gauge soft copper or Copperweld

wire. The Copperweld wire is hard to bend and keep straight, but it is much stronger

than copper and the cost is much less. A staple can be used to fasten the two cage

wires to each of the spokes, preferably on top near the end of each spoke so the

peripheral wire d can be soldered to the two cage wires at each spoke. The top-hat

assembly should be done on the ground before the pole is erected. However, climbing

lugs on the pole will permit assembly and soldering in the air, if desired. A propane

torch is very handy for soldering the wire.

Fig. 3 - Details of the central spoke assembly.

The central spoke assembly supports the widest part of the antenna at a height

of 17 feet 3 inches above the ground. Select straight and clear 16-foot 2 X 4s for

the spokes. These are cut off to extend 15 feet 6 inches from the center of the

pole. Gate hinges fastened to the under sides of the spokes and to the pole with

wood screws support the spokes at the center; the outer ends are held up by the

upper cage wires. Cage wires spread to four inches apart at the end of the spokes

where they are soldered to the peripheral wire. A copper plate is cut as shown in

the detail of Fig. 3 to hold the cage and peripheral wires. The copper plate

is cut out of sheet copper with tabs similar to the kind found on solder lugs. These

tabs are bent over the cage wires and soldered in place. The plate is fastened to

the spoke and then the peripheral wire is soldered in place. It should have some

slack so that when the lower cage wires are soldered in place, there will not be

excessive tension on the peripheral wire and the spokes. In addition, spoke wires

(a in Fig. 1) must be soldered to the peripheral wire and to the pole wires

at the pole. The stub wires (b in Fig. 1) should also be soldered in place.

At the conclusion of all of the soldering and screw-fastening to the spokes, the

top cone should be nicely aligned and tensioned. If it is not symmetrical at this

time, it should be adjusted. This would be a good time to check the dimensions -

an accuracy of ± one inch should be sufficient. The three additional wires on each

face of the bottom cone are soldered to the peripheral wire spaced equally from

spokes.

Fig. 4 - Top and side views of the bottom feed ring. For

clarity, not all of the pole wires and grounding details are shown.

At the bottom of the lower cone (Fig. 4) six one-inch diameter copper pipes

with ends flattened form a ring to which the 30 wires of the lower cone are attached.

Heating the tube ends will make it easier to flatten and bend them. Bronze bolts

3/8 inch in diameter are ideal for holding the lower ring together. Before bolting

the ring together, fasten the insulators to the ring using loop of wire going around

the bronze bolts and placed between the flattened sections of the pipe. Similar

loops of wire connect the insulators to the turnbuckles and 1/4-inch hooks screwed

to the pole complete the tensioning arrangement at the base of the antenna. It might

be simpler to drill all of the holes after the pipes are bolted together. Now is

the last chance to adjust the tension of the wires so it is important to carefully

position the feed ring by blocking it up from the ground and carefully tightening

the turnbuckles. The wires are then fed through the holes in the copper pipes, wrapped

back around the pipe and twisted back on themselves preparatory to soldering. The

blocks are then removed and the turnbuckles are tightened to make the whole structure

rigid. If all wire lengths are okay, older the wires to the feed ring. Two one-inch

copper straps connect from the feed line to the feed ring. Both ends of the strap

are carefully soldered to make good electrical connections to the coax and to feed

ring, respectively. If solid coaxial cable is used, the end must be carefully wrapped

with electrical tape to prevent the entry of moisture.

Two guy lines of polyethylene (water-ski rope) stabilize the antenna and keep

it from twisting (see Fig. 1.).

About 4200 feet of wire is used in the ground system. Luckily, it does not have

to be copper. Galvanized No. 10 steel wire is almost as efficient and much cheaper

to use. If desired, the ground wires can be laid along the surface rather than being

buried. If burial is desired, a small garden plow will reduce the amount of coolie

labor.

Each ground radial is stretched out from the pole and anchored to a temporary

stake. The grass and underbrush should be cleared away so the wire will be flat

on the ground. It can be held down with large staples driven into the ground which

will hold the ground wire in place until the growth of vegetation binds the wires

in place. Five foot by 3/8 inch diameter galvanized rods are driven into the ground

at the end of every third radial where the radial is soldered or clamped to the

rod. A circular wire ties all of the ground rods and remaining radials together

as shown in Fig. 4.

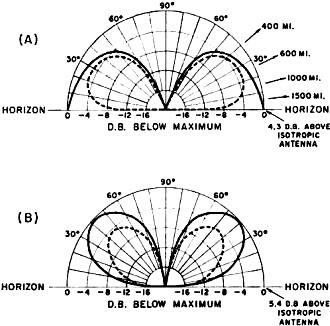

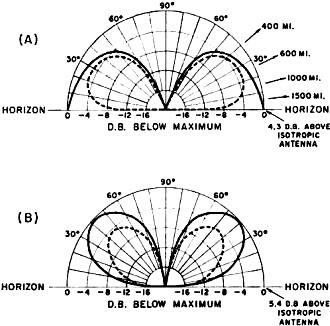

Fig. 5 - Radiation pattern for (A) 80 meters and (B) 20

meters. Solid patterns are for conical monopole over perfectly conducting ground;

dashed, for average soil.

After all of that work, what do you have? The performance can best be shown in

the elevation plane patterns given in Fig. 5. The dotted curves are typical

for average soil conditions. The specified ground screen will improve the patterns

by about 1 db. at low angles. It is easy to see how effectively the antenna concentrates

energy at low angles for long one-hop path. It is not very effective for 100 miles

but for this local work, any old horizontal antenna is adequate, and v.h.f. is a

better answer. The radiation pattern is not too good on the 20-meter band where

radiation is too high above the horizon, but the 40-meter pattern is almost as good

as on 80.

lf it is desired to use this antenna for 40-, 20-, and 10-meter operation, then

all dimensions should be multiplied by 0.543. However, a horizontal beam is usually

a better choice. Only a few amateurs will have the space and the ambition for building

this antenna, but for those who do, it will greatly improve communication.

Parts List of Major Items

48-foot pole 4200 ft. No. 10 galvanized wire 900 ft. No. 10 copper or

Copperweld wire 6 10-inch turnbuckles 6 3/8 inch bronze bolts and nuts insulators,

6 to 9 inches long 15 ft. one-inch copper pipe 6 screw hooks, 1/4 X 6 inches

2 copper straps, 1 X 26 inches 3 2 X 4s, 5 feet long 6 2 X -4s, 16 feet

long 1 polyethylene rope, as needed 6 gate hinges 1 16-gauge galvanized

steel, 18-inches diameter 20 galvanized or copper-plated ground rods, 5-feet

long

1 The Radio Amateur's Handbook, 42nd edition, Fig. 14-1

Posted May 5, 2021

(updated from original post on 3/29/2013)

|

News releases on the new WWV mention the use

of "conical monopole" antennas, and the same antenna has been seen at many military

installations. While the antenna is possibly a bit "rich" for the blood of most

hams, it is still interesting to know how it is constructed. The antenna was developed

and is sold by Granger Associates.

News releases on the new WWV mention the use

of "conical monopole" antennas, and the same antenna has been seen at many military

installations. While the antenna is possibly a bit "rich" for the blood of most

hams, it is still interesting to know how it is constructed. The antenna was developed

and is sold by Granger Associates.