|

November 1940 QST

Table of Contents Table of Contents

These articles are scanned and OCRed from old editions of the ARRL's

QST magazine. Here is a list of the QST articles I have already

posted. All copyrights are hereby acknowledged. |

A new word has been added to my personal

lexicon: "sphenoidal." Author John Kraus used it to describe the wedge shape of

a corner reflector. The

Oxford Dictionary defines "sphenoid" thusly: "A compound bone

that forms the base of the cranium, behind the eye and below the front part of the

brain. It has two pairs of broad lateral "wings" and a number of other projections,

and contains two air-filled sinuses." This "square

corner" configuration - essentially a "V" shape, is shown to exhibit up to 10

dB of gain while being relatively (compared to a parabolic reflector) insensitive

to physical size and driven radiator placement across a wide band when made sufficiently

large. No radiation pattern was included so I posted one from a U.S. government

website. A new word has been added to my personal

lexicon: "sphenoidal." Author John Kraus used it to describe the wedge shape of

a corner reflector. The

Oxford Dictionary defines "sphenoid" thusly: "A compound bone

that forms the base of the cranium, behind the eye and below the front part of the

brain. It has two pairs of broad lateral "wings" and a number of other projections,

and contains two air-filled sinuses." This "square

corner" configuration - essentially a "V" shape, is shown to exhibit up to 10

dB of gain while being relatively (compared to a parabolic reflector) insensitive

to physical size and driven radiator placement across a wide band when made sufficiently

large. No radiation pattern was included so I posted one from a U.S. government

website.

The Square-Corner Reflector Beam Antenna for Ultra High

Frequencies

Fig. 1 - A radiator with a parabolic reflector is shown

at A. A radiator with a "corner" reflector is shown in perspective at B and in cross-section

at C.

By John D. Kraus, W8JK

Here is an antenna system particularly suited to u.h.f. work that combines considerable

gain with no necessity for critical adjustment and tuning. It has a gain approaching

10 db over a single half-wave antenna, can be either horizontally or vertically

polarized, and can be folded for transportation when used for portable work.

The small physical size of ultra-high-frequency antennas makes many designs practical

which are not feasible to build on lower frequencies. The sheet reflector is an

antenna of this type. Sheets in the shape of a section of a parabolic cylinder have

often been used. Fig. 1-A shows such a reflector with a driven radiator situated

at the focus, one of the first directive types of antennas ever tried.

The parabolic reflector antennas are analogous to the parabolic reflectors or

mirrors used in optical systems. If the parabolic reflector is sufficiently large,

so that the distance from the focus to the reflector is many wavelengths, optical

conditions are approached. However, if the reflector is of the same order of dimensions

as the operating wavelength, or less, the analogy to optics is not complete, since

the driven radiator is appreciably coupled to the reflecting sheet.

Fig. 2 - Horizontal square-corner reflector antenna with

grid-type reflector.

Another type of reflector, which forms a very practical and effective system,

consists of two flat conducting sheets which intersect at an angle so as to form

a corner. This system has been termed a "corner" reflector antenna.1, 2

Fig. 1-B is a perspective view of a typical corner reflector antenna. The

same antenna is shown in cross-section in Fig. 1-C. If the driven radiator

is situated on the line bisecting the corner angle, as shown, the maximum radiation

is also in the direction of this line. There is no focus point for the driven radiator

as with a parabolic reflector, and the radiator can be placed at a variety of positions

along the bisecting line. Because of the shape of the reflector, it might also be

appropriately referred to as a "V" reflector or a "sphenoidal" (wedge-shaped) reflector.

An advantage of the sheet reflector is that, if the sheet is sufficiently large,

its dimensions are not critical as to frequency. Hence, the reflector can be put

into operation without the need for any tuning adjustments.

The corner reflector antenna is particularly suitable for use on the higher frequencies

where structures one or two wavelengths in maximum dimensions are practical to build.

Tests indicate that parabolic reflectors of this size have no particular advantage

in performance over the corner type. On the other hand, the corner type has the

advantage of being simpler to construct.

The reflecting sides are flat and are readily adapted to a folding structure

for portable work. The corner reflector antenna constitutes a distinct type of antenna

system having unique properties and characteristics which make it especially suitable

for use as a beam antenna on the ultra-high-frequencies.

The two sheet reflectors of the corner antenna may be arranged to intersect at

a variety of angles. When the sheets intersect at right-angles, the system is referred

to as a "square-corner" reflector.1

Corner angles larger than 90° can be used, with some decrease in gain. A

180° "corner" is equivalent to a single flat sheet reflector, and this may be

regarded as a limiting case of the corner type of reflector. The application of

a single flat sheet reflector to a directional system has been discussed by George

H. Brown.3

Corner reflectors with angles smaller than 90° are also practical. Theoretically,

the gain increases as the corner angle is decreased. However, to fully realize this

gain it is necessary that the size of the reflecting sheets also be increased. For

a structure of the smallest size consistent with a substantial power gain and high

directivity, the 90° corner offers a practical compromise. Accordingly a square-corner

reflector will be described which is especially suitable for amateur use on the

ultra-high-frequencies.

Instead of employing solid sheets, a very practical arrangement is to use a number

of parallel wires or conductors to simulate the reflecting sheet. Fig. 2 is

a perspective drawing of a square-corner antenna with a grid-type reflector. The

parallel conductor arrangement is cheaper, more effective, and presents relatively

little wind resistance as compared to solid sheet or many screen-type reflectors.

For these reasons, the grid-type reflector is recommended.

Construction and Dimensions

Fig. 3 - Construction of a square-corner reflector antenna

with grid-type reflector. With the antenna vertical, A is the top view and B the

side view. With the antenna horizontal, A is the side view and B the top.

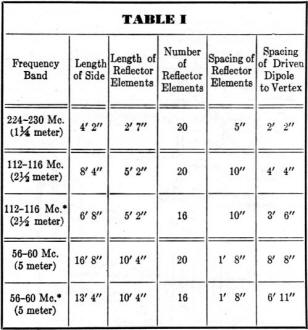

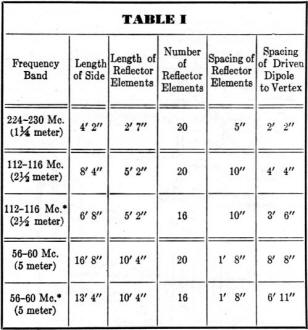

Table 1. - Dimensions of square-corner reflector for the 224-,

112-, and 56-Mc. bands. Alternative designs are listed for the 112- and 56-Mc. bands.

These designs, marked (*), have fewer reflector elements and shorter sides, but

the effectiveness is only slightly reduced. There is no reflector element at the

vertex in any of the designs. The construction is shown in Fig. 3.

Fig. 4 - Method of mounting a square-corner reflector for

horizontal operation (A), and for vertical operation (B).

Fig. 3 shows the construction for a square-corner reflector with dimensions

for the 224- to 230-Mc. band (1 1/4-meter band). The dimensions for this band are

also listed in Table I, which, in addition, gives dimensions for the 112- and 56-Mc.

bands. The dimensions for the 112-Mc. antenna are twice, and the 56-Mc. antenna

four times those for the 224-Mc. antenna.

Furthermore, alternative dimensions are given for 112-Mc. and 56-Mc. square-corner

reflectors of somewhat smaller overall dimensions. These are suitable where the

bigger reflectors would be inconveniently large. The decrease in size causes only

a slight reduction in performance.

As shown in Fig. 3, the main supporting structure for the reflector is an

A-shaped frame. The two sides of this"A" frame are about one wavelength long and

are joined at right angles at the vertex. These side members carry the reflector

elements. A cross-member joins the two side members and carries the driven element

or radiator. The distance between the driven radiator and the vertex, or corner,

is not critical and can be varied over rather wide limits with little change in

the directivity of the antenna. Especially suitable values are between 0.35 and

0.5 wavelength. A value of 0.5 wavelength is recommended for the antenna described.

This amounts to 26 inches for the 224-Mc. antenna.

At a spacing of 0.5 wavelength from the driven dipole to the vertex, the radiation

resistance of the driven dipole is a maximum. It is, in fact, almost twice the radiation

resistance of the same driven dipole when alone in free space. Under these conditions

the effect of losses in both the driven dipole and the reflector is minimized, making

for maximum radiation efficiency. In order to realize the full benefit of this high

radiation resistance, the use of a closely-spaced director with a corner reflector

system is not recommended. However, a few directors spaced at intervals of 3/8 wavelength

can be used to advantage. This high radiation resistance is an important advantage

of the corner reflector over the close-spaced 3- or 4-element beam in which the

low feed point resistance is a limiting factor to the efficiency.

Smaller spacings of driven dipole and vertex are entirely practical, but at a

slight sacrifice in efficiency. The alternative design for the 112- and 56-Mc. square-corner

reflector in Table I has a dipole-to-vertex spacing of 0.4 wavelength. At this spacing

the driven dipole radiation resistance is still somewhat higher than its free space

value, but is considerably less than when the spacing is 0.5 wavelength.

The driven dipole is situated at the mid-point of the cross-member so that it

is equidistant from the two planes of reflector elements. The side member, which

supports the reflector elements may be of either wood or metal, there being no appreciable

difference in operation whether the mid-points of the reflector elements are electrically

connected or not. The reflector wires should be No. 12, No. 10, or larger diameter.

For the 224-Mc. reflector, No. 12 or 10 wire is sufficiently stiff to be self-supporting.

For the 112- or 56-Mc. bands, heavier wire or tubing may be required. A satisfactory

method of securing the reflector conductors to the supporting structure is shown

in Fig. 3-C. Holes are drilled for the reflector elements along the wooden

supporting member. After the conductors are in place they are fastened by a tie

wire.

If portable operation is contemplated, a hinge may be installed at the corner

to join the side members as in Fig. 3-A. The cross-member carrying the driven

dipole is held in place by clamps so that this member can then be removed and the

reflector folded flat. Additional hinges can be located mid-way along the side members

so that the reflector can be folded into a still more compact form. Instead of fastening

the reflector elements in place as indicated in Fig. 3-C, they can be held

by fuse clips mounted on the" A" frame. With this construction, all of the reflector

elements are easily removed and can be tied in a bundle for transport.

The reflector elements are about 0.6 wavelength long. Their length is not at

all critical, slight increases or decreases in length producing no noticeable difference

in performance. This means that the performance of the reflector is substantially

uniform over a wide frequency band.

Multi-Band Operation

Not only is the reflector effective on the band for which it is designed but

also on all higher frequencies as well. The reflector is, thus, suitable for multi-band

operation. A square-corner reflector designed for the 56-Mc. band can be used effectively

on both the 112- and 224-Mc. bands with no change required in the reflector. Some

improvement may, however, be obtained on the higher frequency bands by adding more

reflector elements between those already in use so that the spacing does not exceed

about 0.1 wavelength between elements on the highest frequency used. On the lower

frequencies, the closer spacing of the reflector elements produce very little difference

in performance. If anything it results in a slight improvement. In multi-band operation

with the same reflector, different driven dipoles are employed for each band, with

the spacing to the vertex adjusted to approximately 0.5 wavelength on the band being

used.

Frame Construction

A style of construction different than the one described for the corner reflector

is to support the ends rather than the mid-points of the reflector elements. This

type of construction requires two rectangular wooden frames, one for each reflecting

plane. These frames can be similar in construction to the frames for ordinary window

screens. The length of the frame is made equal to the side length given in Table

I, and the width equal to the reflector element length. Although somewhat heavier

and bulkier, this construction is an entirely practical one. The first tests on

a corner reflector at W8JK were made with a reflector supported on a wooden frame

of this type.1 No. 12 or No. 10 wire can be used for the reflector elements.

The wires are secured to the frame by means of nails or screws. Painting or varnishing

of the frame is desirable. The wires of the reflector curtain are not electrically

connected at any point.

Fig. 5 - Driven dipoles for use with a square-corner reflector.

Fig. 6 - Possible ways of leading the feed line from the

driven dipole to the transmitter with antenna horizontal (A) or vertical (B).

The corner reflector antenna is suited for the transmission or reception of either

vertically or horizontally polarized waves. For vertical polarization Fig. 3-A

represents the top view of the antenna, and Fig. 3-B, the side view. For horizontal

polarization, the driven dipole and reflector are turned horizontal, and Fig. 3-A

then represents the side view and Fig. 3-B the top view of the antenna.

Whether horizontal or vertical polarization is used is largely a matter of individual

preference.

However, it is generally desirable to use the same type of polarization for both

transmitting and receiving unless, due to reflections over some particular path,

tests indicate that different polarization at the transmitter and receiver is preferable.

For horizontal operation a practical method for supporting the entire antenna

is shown in Fig. 4-A. An extension of the cross-member of the antenna frame

is fastened to a mast. In the case of vertical polarization, the mast can be fastened

to an additional member placed between the cross-member of the frame and the corner,

as shown in Fig.4-B.

Another method of support, suitable for either vertical or horizontal operation,

is by means of rope bridles tied to the reflector structure, so that the entire

system can be pulled up alongside a tower or supported between two towers.

As regards the height of the antenna, it is in general true that to transmit

the maximum distance on the ultra-high-frequencies, the antenna should be placed

as far above the ground as possible.

Driven Dipole

Once constructed, no adjustments are necessary on the corner reflector. This

is an important advantage over antennas which require tune-up adjustments before

maximum performance can be realized. With the corner reflector, it is only necessary

that adjustments be made on the driven dipole to obtain maximum input to this radiator.

The type of driven radiator used with a corner reflector is largely a matter

of individual preference. A wide variety of driven dipoles having coaxial or open-wire

feed can be used successfully.

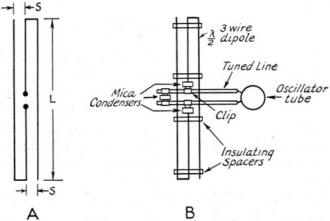

Two systems using open-wire feed are shown in Fig. 5. If the distance between

the antenna and transmitter is relatively short, such as 1 or 2 wavelengths, a tuned

line is satisfactory for feeding the center of a single conductor half-wave dipole

as shown in Fig. 5-A. The dipole length is computed in the usual manner, being

5 or 6 per cent less than a free-space half-wave.

If the distance from the antenna to the transmitter is somewhat greater, such

as two or more wavelengths, a matched impedance feed is more satisfactory. An arrangement

of this type is shown in Fig. 5-B, the driven radiator being a 2-wire half-wave

dipole.4, 5, 6 Carter5 refers to a radiator of this type as

a "folded dipole." Dimensions for a 224-Mc. 2-wire dipole are:

length (L) = 25 inches

spacing (S) = 1 inch.

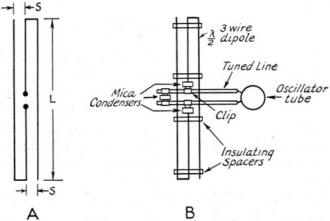

Fig. 7 - 3-wire half-wave dipole (A) and method of mounting

to tuned-line transmitter (B).

Fig. 8 - Measure horizontal directional pattern for a vertical

224-Mc. square-corner reflector antenna of the type described.

For the 112-Mc. band, these dimensions (both length and spacing) are doubled

and for the 56-Mc. band, the dimensions are multiplied by four. Both wires are the

same diameter. No. 12 or 10 wire is satisfactory for a 224-Mc. dipole. Larger wire

or tubing can be used on 112 and 56 Mc. A transmission line of 450 to 500 ohms characteristic

impedance (No. 12 wire spaced 2 inches) is used to feed the dipole. This line can

be coupled to the transmitter tank circuit by a coil of one or more turns. The coil

should be arranged symmetrically with respect to the transmitter tank.

Several possible locations for the transmission line are shown in Fig. 6.

The locations in Fig. 6-A are suitable when the antenna is horizontal and the

paths in Fig. 6-B when the antenna is vertical. Inside of the reflector, the

transmission line should be kept substantially in the plane of the supporting members,

or "A" frame. The line should be supported as symmetrically as possible and sharp

bends should be avoided.

If the distance between the antenna and the transmitting equipment is many wavelengths,

it may be advantageous to locate the transmitter at the antenna with filament and

modulated plate voltages supplied by a 3- or 4-wire cable. This arrangement is well

suited for use with low-power equipment on 112 and 224 Mc. where simple oscillator

transmitters are permitted. The oscillator tube and associated circuits are placed

in a weatherproof box with the antenna protruding. An antenna especially suited

for use with this kind of an installation is the 3-wire half-wave dipole.4(B,

C) The terminal resistance is relatively high and the antenna can be directly

connected to the oscillator circuit, no transmission line being use? A 3-wire dipole

is illustrated in Fig. 7-A, while Fig. 7-B shows a tuned-line oscillator

with the terminals of a 3-wire dipole connected by clips to the line. The point

of attachment may be adjusted for maximum power transfer to the antenna. A pair

of condensers (mica 0.002 μfd.) between the antenna terminals and the clips keeps

d.c. voltages from reaching the antenna. The same size wire is used for each of

the 3 wires of the dipole. A 224-Mc. 3-wire dipole has a length, L, of 24 inches

and a spacing, S, between adjacent wires of 0.5 inch. For the 112-Mc. band these

dimensions are doubled. The power cable supplying the transmitter should be arranged

to follow a path similar to one of those suggested for the transmission line in

Fig. 6.

There is no appreciable difference in the directivity of a 2- or 3-wire half-wave

dipole. When used with a square-corner reflector, the 2-wire is better suited for

use with a transmission line and the 3-wire with the transmitter at the antenna.

In addition to the systems described, in which the antenna is fed at the center,

end-fed antennas can also be used. End feed is best adapted to vertical antennas,

the feed point being the lower end. Any of the common types of end feed, such as

the "J" stub type, can be used.

Performance

Tests have been made on many types of corner reflector antennas at W8JK. The

measured directional pattern of a 224-Mc. square-corner reflector is shown in Fig. 8.

The antenna is vertical and the pattern is in the horizontal plane. The construction

is as shown in Fig. 3. The dimensions are approximately the same as given in

Table I A 3-wire half-wave driven dipole is used with the transmitter located at

the dipole as in Fig. 7-B.

The measured front-to-side and front-to-back ratios are high, 25 db for the front-to-side

and 35 db for the front-to-back ratio. At an angle of 10° from the center line

of the beam, the signal is 1 db down; at 20° 3 db, 30° 6 db, 40° 10

db, 50° 16 db, 90° 25 db and 180° 35 db down. The directional pattern

is very smooth, being free from minor lobes of any appreciable size. The power gain

of the antenna approaches 10 db over a comparison half-wave dipole in free space

with the same power input.

In conclusion, it may be said that the square-corner reflector gives a large

power gain, high directivity, and is capable of excellent performance as a beam

antenna on the ultra-high-frequencies.

1 J D. Kraus, "The Square-Corner Reflector," Radio, March, 1939.

2 J. D. Kraus, "The Corner Reflector," Proc. I.R.E., Sept., 1939, p. 613 (abstract

of paper given at N. Y. C. Convention of I. R. E., Sept., 1939.

3 G. H. Brown, "Directional Antennas," Proc. I.R.E., Jan., 1937, p. 122.

4 (A) J. D. Kraus, "Multi-wire Doublet Antennas," Radio, May, 1939, p. 24; (B)

"Multi-wire Type Antennas," Radio, June, 1939, p, 21; and (C) "Multi-wire Dipole

Antennas," Electronics, Jan., 1940, p. 26.

5 P. S. Carter, "Simple Television Antennas," RCA Review, Oct., 1939, p, 177.

6 J. D. Kraus and S. S. Sturgeon, "The T-Matched Antenna," QST, Sept., 1940,

p. 25.

|