|

March 1933 Radio-Craft

[Table

of Contents] [Table

of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Craft,

published 1929 - 1953. All copyrights are hereby acknowledged.

|

If this article had appeared in

an April edition of Radio-Craft magazine, I might have suspected it was

a Fool's hoax, but it was the March 1933 issue and, it turns out, it was serious.

Obviously the "filamentless tube" concept did not work out well since the overwhelming

majority of vacuum tubes sold up until the time semiconductors took over the electronic

device market had separate filaments (heaters). It was a great idea, though, and

the world is thankful for the pioneers who take the figurative "arrows" for the

rest of us. We benefit from their hard work and ingenuity, while they suffer the

agony of defeat, with an occasional taste of the thrill of victory (ref. ABC's

Wide World

of Sports). It is too bad the concept did not work because, as pointed

out in the article, the benefits of simpler, cheaper manufacturing and greatly extended

tube lifetime would have been a significant asset to the electronics industry.

And Now - The Filamentless Tube

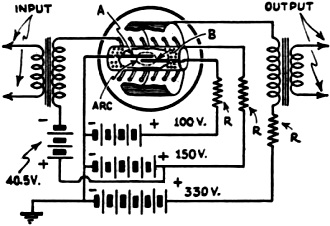

Fig. 1 - Illustration of one type of filamentless tube along

the lines suggested by Dr. Hund at his recent lecture in New York. This tube is

drawn approximately to scale, and the location of all the elements is clearly indicated.

The type of tubes described in this article are not pipe dreams,

but actually have been constructed and successfully demonstrated. While the total

power required to work the tube is slightly greater than a corresponding filament

tube, the extremely long life it enjoys more than compensates for this slight increase

in power. Then again, the necessity for filament transformers is not present. Of

considerable manufacturing importance is the comparative leeway in gas pressure

allowed, and the tube may even function with about 10 mm. of air alone! The materials

used as the elements are not critical, both as to type and purity; a plate, for

instance, may be of iron, and this iron may be either clean or rusty - the results

are the same. It is expected that commercial tubes may be available in about one

year.

Radio-Craft takes pride in presenting a description of one type

of American filamentless tube.

Tubes of various types and classes have been described in this and other publications

since the latter part of the nineteenth century; but, in nearly every case, the

tubes described employed a filament as the primary source of electrons. Ionization

of gas has been suggested as a means of securing electron emission, and a great

deal of work has been done along this line in Germany. We herewith present the first

complete description of an American filamentless tube, recently demonstrated in

New York.

A furore was created at the January, 1933 meeting of the Institute of Radio Engineers

when Dr. August Hund, a member of the research staff of Wired Radio, Inc., discussed

the development and demonstrated the operation of filamentless ("cold-cathode"),

or ionized-gas, tubes. (Based on the fundamental experiments of Dr. Lee DeForest,

nearly thirty years ago, as mentioned in the article, "Soon-The Cold-Cathode Vacuum

Tube," in the May, 1931, issue of Radio-Craft - Technical Editor.) Over 1,000 engineers

listened to every word of this well-known scientist and pioneer in the development

of ionized-gas discharge devices. In a short address, just before the discussion

of Dr. Hund's paper by members of the Institute, Mr. R. D. Duncan, Jr., chief engineer

of Wired Radio, Inc., stated that the primary interest of his company in new tube

developments was in long life, because of the tremendous cost it would be for his

company to service burned-out tubes in the rented receiver system they plan to install

shortly in Cleveland, Ohio.

Uses of Filamentless Tubes

The experimental tubes demonstrated by the Doctor were put through the paces

of oscillation, detection (or demodulation, as the Doctor chose to call it), voltage

amplification, and power amplification. The tubes of the power class operated as

class B, push-push devices. Oscillations were produced by feedback circuits.

A four-tube set (contained in a cabinet of conventional design) demonstrated

beyond a doubt, when music and speech of excellent quality filled the packed auditorium,

that the filamentless tube can rival the filament tube in performance! (A beautiful

lavender glow; sufficiently strong to permit the reading of newspaper print a short

distance away, emanated from the ends of the tubes' cathodes.) A one-tube set gave

loudspeaker volume that would be sufficient for any hotel room.

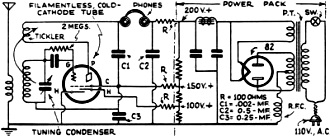

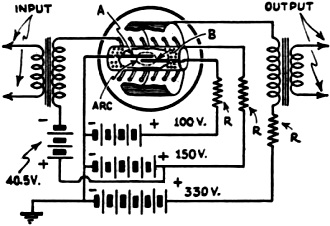

An experimental tube design shown and described is illustrated in Fig. 1;

a schematic circuit of a "1-tube loudspeaker set," designed in accordance with the

engineering data given verbally and via the blackboard by Dr. Hund, is shown in

Fig. 2; a theoretical amplifier circuit is Fig. 3. It must be remembered

that although experimental work is still continuing, commercial tubes are not yet

available, and hard and fast figures cannot be given.

Two general types of tubes have been developed, one of which is a five-electrode

tube that makes use of the conduction of negative ions, while the other is a two-electrode

tube operating on the negative resistance principle involved in the operation of

the Poulsen arc. Both types of tubes have been made to function as oscillators,

amplifiers, modulators and demodulators, and several forms of amplifier tubes working

on both the ionization and negative resistance principles were described, but the

design of greatest interest to the average radio man is the former or "ionization"

type.

The "Uniode" Filamentless Tube

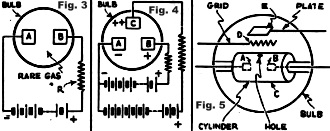

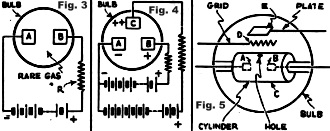

In Fig. 4 we have the first blackboard illustration sketched by the Doctor.

In this elementary form of tube, we have the basis of many already commercialized

devices. A globe with about 10 or 20 mm. of some inert gas encloses two electrodes,

a cathode A and an anode B; a high-voltage battery and limiting resistor R complete

the circuit. This resistor limits the current through the tube, which current otherwise

would reach an excessive value due to the low resistance of the ionized gas.

With the battery current adjusted to a value that is not critical, we have a

glow between the electrodes. The color is pink for neon, and lavender or purple

for helium. This glow is thought to be caused by the collision of positive ions

and electrons dissociated by the highly charged electrodes A and B.

This "uniode" tube can be made to detect, oscillate and amplify; also, relaxation

oscillation has been produced from low audio frequencies to 30,000 kc. (10 meters),

according to Dr. Hund. However, these two-element tubes have serious limitations

when compared to the orderly working thermionic class used in our present receivers,

and, therefore, it was found necessary to modify the design in order to more closely

approximate the performance of filament-type tubes. At the same time, the feature

of unlimited life was obtained. This modification, Fig. 5, is the introduction

of a third element marked C.

How the Diode Cold-Cathode Tube Operates

The dissociation of electrons and positive ions from the rare-gas atom, as explained,

makes it possible to pull great quantities of negatively charged ions and electrons

to the third electrode, which is charged "plus plus" (the Doctor's terminology),

or at a higher voltage than electrode B. We now have one stream of electrons and

ions between A and B, and another to C. In a hot-cathode type diode tube the filament

may be likened to the path A-B, and the internal plate circuit as the electron stream

to C.

So far, the talk had only reviewed the work of previous investigators, continuing

with the remark that as soon as a grid was put between the arc and the plate C,

the grid becomes charged with positive ions and causes it to become inoperative.

This was the starting point for the description of the structural changes which

made the filamentless triode practical.

Construction of the Filamentless Triode

The next blackboard sketch, Fig. 6, showed the introduction of a perforated

electrode in place of C in Fig. 5; the introduction of a grid D and plate E

completed the representation of a triode which may be designed for any service.

The action was explained as follows: Electrons and positively charged ions from

the arc between A and B are accelerated through the perforated cylinder; for purposes

of explanation, only one of the small holes is shown. (See Fig. 1.)

The shielding effect of this positively charged cylinder slows the speed of the

positively charged ions so that there is practically no trace of this trouble maker

in the electron stream between the cylinder and plate. A grid in the electron stream

now affords complete control of the operation of the tube, similar to any triode.

In order to obtain power from the tube, the entire surface of this cylinder,

or "cathode," must be perforated, as shown in Fig. 3. (These holes measure

about 40 mils in diam.) This gives us an electron stream second to none; not even

the best of filament or hot-cathode emitters. Once the electrons are drawn through

this cathode, the operation of the tube is exactly analogous to the operation of

hot-cathode emitters, and the glass envelope, therefore, may contain all the additional

electrodes necessary to produce a diode, triode, screen-grid quadrode, pentode,

and, if the tube industry finds need for such, a septode or heptode.

By placing the grid and plate all the way around the cylinder it was found possible

to take advantage of the electrons coming through all the holes; this is the controlling

factor which enabled the Doctor to design almost any kind of a tube, be it for voltage

or power amplification, or detection or oscillation. The corrugated appearance of

the plate electrode (which very much resembles a biscuit-cutter) is explained when

it is recalled that if it were not corrugated the electrons would tend to be drawn

to that point on the surface of the plate which is nearest the cathode - because

of mechanical asymmetry - and corrugating the plate tends to result in the electrons

being drawn through all the holes in the cathode and distributed over the entire

area of the plate (provided the elements are symmetrically positioned with the usual

commercial tolerances).

Characteristic Data

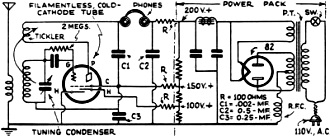

Fig. 2 - Schematic circuit of a one-tube receiver using

the filamentless tube described in this article.

Fig. 3 - A theoretical circuit illustrating the use of the

filamentless tube as an amplifier.

Fig. 4 - Simple circuit of an elementary gaseous two-element

tube.

Fig. 5 - Same as Fig. 4, with a third element, C, inserted

and charged.

Fig. 6 - Simple schematic of the filamentless tube showing

the use of the holes.

Although it is regretted that curves of the static and dynamic characteristics

of the experimental tubes described by Dr. Hund are not available at the present

time, considerable information may be obtained from the figures given and from known

data regarding the operation of gas discharge devices.

A potential of 100 volts is shown in Figs. 2 and 3 as the value required to produce

ionization between the two overlapping electrodes; this figure, however, will depend

entirely upon individual tube design. The current required to produce sufficient

ionization for operation, in the desired service is another variable factor; in

one tube model this figure was 60 ma. The "power" consumption of this ionized path

(equivalent to the more usual "filament.") is, therefore, 6 watts. In both Figs.

2 and 3 the cathode is shown placed at a potential 50 volts above that required

for normal ionization, or 150 volts; the cathode current consumption will vary with

tube design.

The grid and plate voltages, shown in Fig. 2, are those usually employed

for grid-leak detection using certain types of hot-cathode triodes (zero grid bias,

and 50 volts on the plate with equivalent plate current drain). The grid and plate

voltages, and plate current of Fig. 3 parallel the figures for operation of

a type 71A tube used as an amplifier. As Fig. 2 indicates, it makes no difference

whether the operating potentials for a filamentless tube are obtained from batteries

or a "B" eliminator, provided correct bypassing is secured in the latter instance.

Grid input impedances may run as low as 30,000 ohms and as high as present tubes.

Output impedances can be made to match present tubes so that present transformers

can be used. The power transformer must be designed to accommodate the additional

150 volts required by the ionizing and cathode circuits at the current drain of

the particular tube types.

At the conclusion of the reading of Dr. Hund's paper, it was not necessary for

the President of the Institute to ask for a rising vote of thanks as the audience

showed their appreciation of this amazing development by long and loud applause.

The discussion which followed brought to light several interesting points.

The Discussion

For instance, it was brought to light that some heat is developed by electron

bombardment of the electrodes; however, this heat is carried off through the stem

of the tube by conduction, and does not reach a temperature .high enough, for instance,

to burn the hand.

In answer to another question; it was explained that the material used for the

electrodes did not make much difference. In some tubes the electrodes were made

of iron, while in others aluminum and nickel. The iron could be rusty, oily, and

dirty; clean: electrodes were no better than dirty ones.

The kind of gas used did not seem to make any differences; combinations also

did not exhibit any differences in operation. Chemically pure gas reduced the ionizing

potential from about 100 volts, which was not considered too high, to as low as

35 volts. The amount of gas was usually between 10 and 20 millimeters, but Dr. Hund

said he obtained quite satisfactory operation by using only ordinary air exhausted

to 10 mm., and without the addition of any other gases. (Apparently occluded gases

cause little trouble in a tube of this type, and since high evacuation on expensive

pumps is one of the most costly procedures in the manufacture of present-day hot-cathode

tubes, it follows that a marked saving should be affected in the procedure of manufacturing

cold-cathode tubes.)

The doctor explained to another engineer that the insulation within the tube

was carried right up to the electrodes by extending the glass to the point of contact

with the electrodes. This is done in order to prevent "sputtering" or uncontrollable

sparking from point to point which otherwise occurs in gas-filled tubes.

Although the inquiries of four engineers and the impromptu calculations of another

tended to indicate that the over-all power consumption of a tube of the filamentless

type exceeded that of the filament type, it was pointed out that the practically

"lifetime" longevity of the tube, its low cost of production, its freedom, from

variations in characteristics with relatively large changes in gas pressure, the

absence of a filament winding on the power transformer, the ease of reproducing

tubes having a given characteristic, and the simplification of receiver wiring,

far more than offset the added cost of the increase in high-voltage output necessary

to supply the ionization and cathode potentials and currents. Undoubtedly, this

talk by Dr. Hund has done more to stimulate nationwide interest in the cold-cathode

or filamentless type of tube than any other publicity so far.

Posted January 2, 2023

(updated from original

post on 1/22/2015)

|