|

March 1935 Radio-Craft

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Craft,

published 1929 - 1953. All copyrights are hereby acknowledged.

|

Resistors, probably the most common

electronic components in existence, have undergone significant evolution since first

being mass produced in the late 19th century. Amazingly, less than two centuries

have passed since the concept of electrical resistance was first published in 1827

by Georg Simon Ohm,

a German physicist. As with most products of the era, and well into the 20th century,

resistor manufacturing involved a degree of human labor. Resistors (and capacitors

and inductors for that matter) found in your grandparents' old vacuum tube radios

were most likely measured and sorted, and the colored value markings painted by

the hand of a human worker. This "How Resistors Are Made" article from a 1935

issue of Radio-Craft magazine provides a look at the early manufacturing process

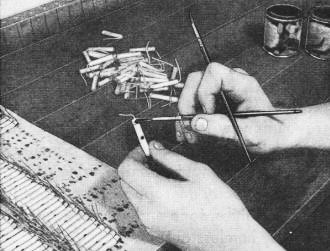

long before salt-grain size surface mount resistors. Note the photo showing an

operator manually painting color code dots on the resistor body. One of America's earliest and largest resistor manufacturers

was based right here in my adopted hometown of Erie, Pennsylvania. Here is a short

feature I wrote on

Erie Resistor Corporation.

How Resistors Are Made

Manufacturing operator applies colored paint for value and

tolerance coding.

Ralph Sayres

The radio beginner has no doubt wondered how resistors are made.

This interesting article tells how the different types are manufactured, including

a new method.

Resistors are now made by an entirely new process, by a well-known manufacturer,

developed over the past six years as a result of intensive study of the different

classes of resistors to eliminate the drawbacks of the general methods heretofore

used.

A study of resistors shows that they fall into three classes, namely: wire-wound

type, carbon-coated or film type, and carbon-composition molded type.

The first class is wire wound, and from a cost standpoint can be disregarded.

The second class is the so-called carbon-coated type, in which a thin film of

carbon is placed on a glass or porcelain rod or tube. In some cases this is spiraled

to vary the resistance. Briefly, this type has generally been discarded today, and

spiraled units are not being made in important quantities now. The film of carbon

is very thin, and therefore, very fragile and unsafe. Mechanically such a structure

is undesirable. Injuries easily occur; adhesion of the film to the supporting surface

is difficult to control; contact is fragile; and transfer of heat energy depends

on mechanical limitations of the whole assembly. The current-carrying capacity must

necessarily be a function of the area or cross section and when the resistance is

increased solely by cutting down the thickness of the film (already very thin),

naturally the current-carrying capacity is impaired, and the current density increases

tremendously. This gives rise to overheating, localized stresses and leads to ultimate

failure and bad characteristics.

The third class is the so-called carbon stick or composition type. It consists

of a mixture of a very small percentage of conducting material (carbon) and an insulating

material molded under relatively low pressures. Practically it really represents

a number of semi-round carbon pebbles which touch each other with a point contact.

Therefore, the paths and areas through which current may travel are reduced greatly

by the large bulk of insulating particles, and this to a tremendous degree further

by the point contact condition.

The current density must be considered microscopically, and consequently has

heretofore not been stressed to the extent its importance warrants. A study of micro-photographs

will bear this out. It shows that the structure of such units is not uniform and

contains many voids, irregularities and inclusions. It is seen that the mass is

not solid but porous and contact is "point" contact only. Therefore the current-carrying

cross section is microscopic, and the current density must of necessity be very

high at such points or areas. This has been proven by studying under high-powered

microscopes the action of the units under both normal and excessive loads. Glowing

points of light were observed proving the intense microscopic current density. Naturally,

such points would tend to alter their characteristics both physically and mechanically.

Further study was made of resistance values under mechanical loads, and the changes

noted under such loads were to be expected in accordance with the above facts.

With these considerations in mind a resistance was developed which technically

and practically would overcome these objections. First, instead of a background

material of very high insulating value, a background material which is in itself

a resistance material has been substituted. To vary this material and o get the

desired resistance values another resistance material of lower value is introduced.

The entire mass, after it has been reduced to absolute uniformity is then subject

to tremendous pressure and under such pressure extruded into rods.

Consider then the result. Instead of a very small percentage of the cross section

being of a current-carrying material, the entire cross-section is current carrying.

Further, the cross-sectional area is not composed of a great number of voids and

a relatively small number of points of contact, but is microscopically one solid

uniform compact current-carrying mass. This is the result of the tremendous pressure,

the method of extruding, and the composition of the material itself. In fact, these

new units are so uniform that they resemble the micro-photographs of a section of

a gun forging. This current-carrying area is large and non-microscopic, and this

in itself explains many other results as shown in the succeeding paragraphs.

A study of these units under mechanical loads, shows that the resistance value

remains constant. This is a most significant fact. Microscopic study under normal

and excessive wattage shows that "light" points, or points of excessive microscopic

current density do not exist.

The Results of Tests

The method of attaching ends to these units has also been subject to a similar

technical study and development. It was desired to secure a uniform sound area of

contact, and then to place on this area of contact a metal surface which in itself

has sufficient strength and rigidity to be positive in its action. The coating of

the ends of the resistor with fine particles of metal produced the first consideration.

The second requirement was met by placing on the end of the resistor and over this

metal-coated surface a solid piece of metal in the form of an end cap to which end

cap was integrally attached the pigtail. In this fashion a much sounder terminal

construction was arrived at than in most instances.

The physical appearance of the unit bears out these facts. One finds a solid

extruded mass., homogenous, and rock-hard which is a conductor throughout its entire

body, has a smooth velvety finish, which in itself is ideal for heat radiation.

The diameter and length is uniform.

Current Rating

The watting ratings are exceptionally conservative for the sizes have been kept

standard (to the usual type resistor dimensions) rather than reduce the bulk in

keeping with the greater wattage dissipating properties of he unique conducting

mass.

These units have been in actual existence and on test for some years and have

been in their final form for more than a year.

The first consideration in testing was to apply load. All loading was applied

initially at double wattage, with no effect on the value of the unit. Increased

load was applied in the presence of elevated temperatures, still the units were

ale to show no change in value. Tests were made on an intermittent basis and the

loads were varied from less than normal to more than double load. Tests were carried

out by many different groups., and were highly satisfactory.

One of the most recent tests shows that not a single unit dropped in value under

various loads up to double wattage and voltage up to 880 volts and greater. Variation

of load of any one unit was less than 2 per cent, but the majority of the units

were fractions of 1 per cent. In fact, loads in excess of 1 watt were placed on

the 1/4-watt units.

These units were tested also under usual humidity conditions and found to be

without change. They were then placed in water for varying periods of time, and

again satisfactory results. Further, these units have been subjected to any unusual

test; such as putting them directly into water; into boiling water; and into live

steam with satisfactory results.

Posted October 20, 2023

(updated from original post on 10/4/2016)

|