|

May 1966 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

If you have ever had the occasion

to service a piece of vintage electronic equipment, then you have surely encountered

instances of capacitors, inductors, resistors, and transformers with color and/or

numeric markings for identification. A lot of today's components are clearly marked

with laser etching or indelible ink (some of it so small as to be barely legible),

but even so, deciphering a component's value can be challenging or even impossible.

Given that most products today are considered disposable or at least non-serviceable,

component marking wouldn't be needed at all except for during automated assembly

and inspection where machine vision is used to verify part type and orientation

on the circuit board. Probably most people in the electronics business are familiar

with the standard EIA color code for numeric value versus color (0=black, 1=brown,

2=red, etc.), but discerning tolerance, power rating, temperature range, and other

parameters can be a real head scratcher. Articles like this one in Radio-Electronics

magazine help take the mystery (and frustration) out of the task.

How to Read Capacitor Codes

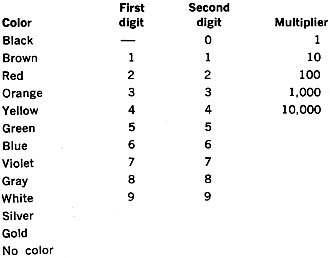

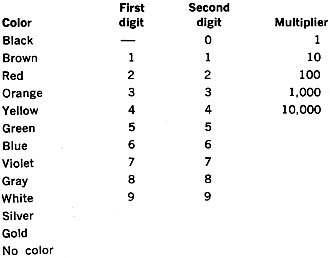

Fig. 1 - Basic capacitor color code.

Unveil the mystery of those three (or five, or six, or nine) colored spots before

your eyes

By Martin Clifford

Pick up a color-coded resistor. You can call off its value and tolerance in seconds,

if you know the code. With some experience, you can even make a reasonably accurate

guess about its wattage rating.

But what about capacitors? The unit you pick up may have a color-code arrangement

of three, five, six or nine dots. It may be coded on one side or both. It may have

bands of colors instead of dots. It may follow IAN (Joint Army-Navy) or MIL (military)

or EIA (Electronics Industry Association) specifications, or it may be coded to

follow a manufacturer's particular requirements. The capacitance may be marked or

stamped in numbers on the unit, or, in some miniature types, the capacitor may have

no direct coding or identification. In such cases information may be on the envelope

that holds the capacitor.

Causes of Confusion

Resistor coding has been fairly well standardized for many years. Why, then,

is there so much confusion about capacitor coding?

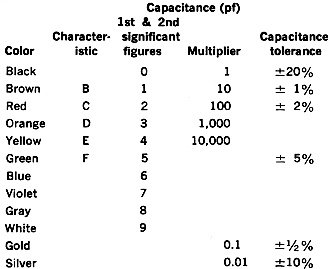

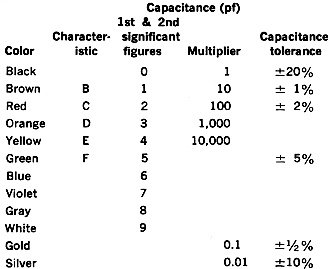

Fig. 2 - Six-dot (EIA) code for mica capacitors.

Fig. 3 - Mica capacitor characteristics.

Fig. 4 - How to read six-dot EIA mica-capacitor code. If first

dot is black instead of white, capacitor conforms to MIL-C-5A specs, almost identical

to data given in Fig. 2.

Fig. 5 - Manufacturer's code for micas.

Fig. 6 - Standard EIA nine-dot mica capacitor code.

Fig. 7 - Three-, five- and six-dot codes that have been used

for mica capacitors.

Fig. 8 - EIA code for molded paper tubular capacitors.

Fig. 9 - Types of color coding used for molded-paper flat capacitors.

Fig. 10 - Coding used on some Mylar or polyester film capacitors.

Fig. 11 - Miscellaneous types of ceramic capacitor color codes:

A - temperature coefficient; B - first significant figure; C - second significant

figure; D - decimal multiplier; E - tolerance.

Fig. 12 - Coding for tubular ceramic capacitors.

Fig. 13 - Tubular ceramic capacitor EIA five-color system (top);

six-color system (bottom).

Fig. 14 - EIA color code for ceramic capacitors.

Fig. 15 - Military designations and corresponding specification

numbers for capacitors.

Capacitors come in an extremely wide variety of sizes and styles, making resistors

look simple by comparison. In dielectrics alone we have air, paper (both Kraft and

metallized), mica (including silvered mica), Teflon, Mylar, Amplifilm, polystyrene,

polyethylene, tantalum oxide, aluminum oxide, ceramic, glass and vitreous enamel.

They have an amazing number of shapes, including flat rectangular, tubular, feedthrough,

button, disc, standoff, bathtub, orange drop, cup type, can type, standard, tiny,

midget, miniature and subminiature. They may be polar or nonpolar.

We demand much more information from a capacitor code than from one used for

resistors. In addition to capacitance we may want to know tolerance, working voltage,

temperature coefficient, type of dielectric and operating temperature range.

Also consider what we ask our capacitors to do. A list of their functions would

start out with blocking, buffer, bypass, coupling, filter, tuning, motor-starting

and temperature compensation.

Capacitor Color Codes

Color codes, in the form of dots or bands, are used for paper, mica and ceramic

capacitors. The amount of information given by the code is directly related to the

number of dots or bands used. When color codes are used, capacitance values are

always in pF (picofarads or micromicrofarads). The basic color code for capacitors

is sometimes considered identical with the resistor code. It is, to a considerable

extent, but the tolerance codings are different. The basic color code for capacitors

appears in Fig. 1.

Mica Cap - the Six-Dot Code

The various characteristics of mica capacitors are called out by a color-dot

arrangement that has ranged from three to nine dots. The present codes have six

or nine dots.

Fig. 2 shows the coding for a standard six-dot system. The characteristic, in

the second column, refers to the temperature coefficient of capacitance and the

maximum capacitance drift. The letters in that column are detailed in Fig. 3. As

with resistors, the multiplier is the factor by which the first and second significant

figures are multiplied to obtain the nominal capacitance.

Fig. 4 shows the dot arrangement with a six-dot code. The capacitor will have

arrows adjacent to the color dots, between them, or both, to indicate the direction

in which to read the dots. Note that the coding does not include the dc working

voltage. The voltage rating may vary from 100 to 1,000 volts dc. Manufacturers may

give case sizes to supply information about the working voltage.

The first dot in the upper row indicates a mica capacitor. This is followed by

the first and second significant figures. The color dot at the lower right is the

multiplier. The dot preceding this is the tolerance while the lower left-hand dot

is the characteristic. The color for the characteristic will be brown, red, orange,

yellow or green.

Example: What can we learn about a capacitor that has white, green and

brown dots across the top, and brown, red and brown across the bottom?

The white first dot indicates that we have a mica capacitor. The next two colors

are the first two significant figures of capacitance, 5 and 1. We read this as 51.

Our multiplier, brown, at the lower right, is 10. Multiplying this by 51 (51 x 10)

gives us 510 pF or 510 μμF, the nominal value of capacitance. The characteristic

(lower left dot) is brown. Fig. 2 shows that this corresponds to the letter B, and

Fig. 3 indicates that this characteristic is not given. The lower center dot is

red. Fig. 2 shows that the tolerance is ±2%.

Manufacturers' Codes The codes given in Figs. 1, 2 and 3 are

EIA codes.

Capacitors may also be stamped with the values (in figures) of capacitance and

tolerance, or with nothing more than a manufacturer's code number. A manufacturer's

code might be a number such as D15. His catalog would show the full number as D155E301JN3.

The number immediately following the letter E (which indicates the characteristic)

reveals the capacitance. The first two digits are the first and second significant

figures of capacitance. The last digit is the multiplier. In Fig. 5 the capacitance

is shown as 301. The last digit is the multiplier and represents the number of zeros

to follow the first two numbers. Thus, we have 30 followed by 0, or 300 pF. If the

last number had been 2 instead of 1, the capacitance would have been 3,000 pF.

Mica Cap - the Nine-Dot Code

The nine-dot code is similar to the six-dot code except that both sides of the

capacitor carry information. One side, with six dots, is identical to the usual

six-dot code. The three dots on the other side, as shown in Fig. 6, indicate the

dc working voltage and the operating temperature range. The final dot is an identifier

and repeats the identifier information on the front of the capacitor.

Mica Cap - Three to Six Dots

A variety of codings, ranging from three to six dots, have been used for mica

capacitors, as shown in Fig. 7. While this coding is obsolete, tremendous quantities

were manufactured and you will inevitably meet capacitors with such coding in your

work.

Paper Capacitors - Tubular, Oil-Filled

Known as tubulars because of their cylindrical shape, these units may come encased

in paper or plastic, and will have an EIA color code consisting of five or six bands.

Oil-filled capacitors, used in high-voltage power supplies and transmitters, are

grouped with the tubulars since their dielectric is also paper. Since they are fairly

large, their capacitance and working voltage are often stamped directly on the case.

To read the value of a paper tubular, hold the capacitor so the color bands are

toward the left. Fig. 8 supplies the code for molded paper tubulars.

The difference between a five-color and a six-color band is in the voltage rating.

A capacitor with five colors follows the voltage rating given in Fig. 8. If the

capacitor has six colors, the last two (at the right when you hold the capacitor

with the maximum number of bands at the left) are both used for the voltage rating.

Multiply the value represented by these two colors by 100, or move the decimal point

two places to the right.

Example: What is the nominal capacitance, tolerance and dc working voltage of

a molded paper tubular whose color coding is brown, black, yellow, orange, brown,

red?

Taken together, the first two colors represent 10. The multiplier, yellow, adds

four zeros, making the nominal capacitance 100,000 pF or 0.1 μF. The fourth color,

orange, indicates a tolerance of ±30%. The last two colors, brown and red,

show that the voltage rating is 12 x 100, or 1,200 volts.

If a molded paper tubular has a rating of 1,000 volts or less, only five colors

are used, the end color representing the voltage indicated in Fig. 8.

Flat Molded Paper and Film Capacitors

The dielectric is the same as that of the tubular units, hence the coding follows

that given in Fig. 8. The coding is in the form of dots, not bands, and may follow

either of the systems shown in Fig. 9. Unlike paper tubulars, though, flat rectangular

paper units mayor may not carry a color coding to indicate the working voltage.

When the voltage rating is not part of the code, it is usually given by the capacitor's

dimensions.

Some color-banded capacitors, about the size and shape of a cough drop or piece

of Chicklets gum, have a Mylar or similar polyester film dielectric. The top band

is the first digit, and the band below is the second. The band closest to the leads

is the decimal multiplier. A drawing of a representative capacitor is shown in Fig.

10 along with its color coding chart.

Ceramic Capacitors

Available in a variety of styles, this type may be either fixed or variable and

coded by dots or bands. Disc types may be color-coded or may have the capacitance

value and other data printed on the unit. The coding may be three, five or six dots

or bands. Fig. 11 shows miscellaneous types of ceramic capacitors while Fig. 12

illustrates the coding of tubular types. A summation of the EIA coding for five-

and six-color systems is given in Figs. 13 and 14.

Miniature Molded Ceramics

When these units use four colors in their code, the first two colors are the

first and second significant figures of capacitance. The third color is the multiplier

and the last color is the tolerance. The colors are numbered according to the EIA

code given in Fig. 1. In some cases, though, manufacturers use a coding system of

their own.

First color Temperature coefficient of capacitance

Second color First significant figure of capacitance

Third color Second significant figure of capacitance

Fourth color Decimal multiplier of capacitance

Fifth color Tolerance of capacitance

First color Sig fig of temp coefficient of capacitance

Second color Mult to apply to sig fig of temp coeff

Third color First sig fig of capacitance

Fourth color Second sig fig of capacitance

Fifth color Decimal mult of capacitance

Sixth color Tol of capacitance

Military Coding

Fig. 16 - Tolerance values of capacitors coded to military specifications.

Figures are plus/minus percentages of nominal capacitance.

Capacitors manufactured for the military may find their way into surplus. A representative

marking consists of a nine-letter code - actually, a combination of numbers and

letters, such as CY30C362J. Fig. 15 gives the description of the capacitor type,

the corresponding military style designation and the applicable MIL specification.

The number 30 following the letters CY refers to the case size. The letter C

following the number 30 refers to the characteristic. You can obtain this information

by consulting Fig. 3, given earlier. The number 362 gives us the nominal value of

capacitance. The first two figures, 36, are the first two digits of capacitance.

The number 2 represents the multiplier, and indicates the number of zeros to follow.

In this example, the capacitance is 3,600 pF. If the multi-plier had been the number

1, the capacitance would have been 360 pF. If it had been a zero, the capacitance

would have been 36 pF.

The last letter of the part number marked on the capacitor is the tolerance and

is given in Fig. 16.

Fig. 17 - Military designation for tubular plastic-cased capacitors.

Capacitors made to military specifications may be coded with a combination of

numbers and letters, but may also use the EIA code with some small modifications.

Thus, molded micas will conform to MIL-C-5A military specs and EIA specification

RS-153. In the six-dot code the dielectric identification (first dot to the left,

upper row) is white for EIA and black as the MIL-C-5A color.

The military designation for plastic molded tubulars is CN22AE202N. The characteristics

corresponding to this number are given in Fig. 17. However, the capacitor color

coding follows the EIA system given in Fig. 8.

|