|

February 1967 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

Irwin Math - what a great

last name. My preferred last name list also includes Piper, Cessna, Rockett,

Wright, Goddard, Einstein, Marconi, Hertz, Coulomb, Ampere, Edison, de Forest.

That is not to disparage other worthy names like Bell, Moore, and Franklin, it's

just that the latter are common enough that they would not likely illicit an

association with an accomplished scientist. If I can't have fame in common with

a great person, at least the name would be somewhat of a consolation. ...but I

digress. This "Digital-to-Analog Fundamentals" article authored by Mr. Math

appeared in a 1967 issue of Radio-Electronics magazine. With the advent of transistors and a

growing selection of integrated circuits, digital signaling and processing was

getting a lot of attention. Univac-size vacuum tube computers were being

compacted into a small fraction of the volume, consuming a small fraction of the

power, and requiring a small fraction of the maintenance. History shows that

rapid progress ensued in both digital circuitry and the application thereof.

Digital-to-Analog Fundamentals

Fig. 2a - Simple digital counting system.

Fig. 2b - The output from the counting system.

By Irwin Math

In today's sophisticated world of electronic computers, automatic control systems

and complex communication networks, many physical and electrical quantities must

be measured and processed with electronics. At present, there are two ways for handling

such information - the analog and the digital methods.

When the value of quantities such as temperature, fluid flow and illumination

level change, they do so gradually and continuously. To measure such analog quantities,

certain sensing devices - thermocouples, flow meters, and photocells, for instance

- are used. The output of a thermocouple is a continuously varying voltage; there

are no jumps or breaks between one point and the next. For example, Fig. 1 is a

graph of the temperature variations during a normal summer day, as measured by a

thermocouple calibrated in degrees F. Notice that the curve is smooth - all temperatures

from the high of the day to the low have been recorded.

Other values - such as the number of boxes on an assembly line or the number

of automobiles passing a toll booth - are called digital quantities. They are composed

of distinct, separate units, never varying continuously but always in discrete steps.

The output of digital sensing devices such as electronic counters, proximity detectors

or photoelectric relays are usually pulses or steps in voltage. Fig. 2-a shows a

high-speed production line with a photoelectric counter, while Fig. 2-b illustrates

the output of the photoelectric cell. Every time an object interrupts the light

beam, a pulse is produced and the counter is triggered. This output, unlike the

analog output, is abrupt. An increase in the number of items passing the photocell

increases only pulse rate. Amplitude remains the same.

Digital-pulse information, unlike continuously varying analog data, is more easily

processed in electronic devices. Flip-flops can quickly count pulses, digital computers

can readily add, subtract, multiply and divide them; and punch cards and magnetic

tapes can store them. It is therefore often desirable to convert analog information

to digital signals. Many devices have been developed to accomplish this, and if

you understand how analog-to-digital converters work, you'll know more about today's

industrial measuring and control systems.

Fig. 1 - Temperature on a summer day.

Fig. 3 - Simple digital-to-analog converter; temperature controls

heating or cooling.

Fig. 4 - This is the basic form of an electronic analog-digital

conversion system.

Fig. 5 - An automobile tachometer uses one kind of digital-to-analog

conversion.

Fig. 6 - This rocket-borne telemetry transmitter uses analog-to-digital

conversion.

As an example, suppose it's desired to keep the temperature of a room at 75°F.

Since temperature is an analog quantity, what's needed is a device to sense 75°F,

to turn on a heater if the temperature falls or a cooling device if it rises. Fig.

3 shows the system. A bimetallic strip is used as the analog-digital converter.

When the temperature is below 75°F, the strip bends up (the analog input) and

the heater is connected in the circuit (the digital output). As the temperature

rises, the strip slowly bends down until, at exactly 75°F, the contact is broken

and the heater turns off. If the temperature should rise above 75°F, the bimetallic

strip bends further down and turns on the air conditioner. Now the cycle reverses,

the contact being broken when 75°F is reached. By varying the settings of either

contact point, various temperatures can be sensed and controlled.

Most analog-to-digital converters are more complex than the previous example.

Consider Fig. 4. In this circuit an analog input of 0-10 volts changes the bias

on Q1 (an npn transistor), thereby varying emitter-to-collector resistance r2. This

change in resistance varies the total resistance (R1 + r2) in the Q2 emitter circuit,

altering the number of pulses per second produced by pulse generator Q2. As a result,

each analog change produces a definite change in the number of pulses. Since fractions

of a pulse cannot be produced, the output is a true digital signal.

Using this system, analog temperature information can be read out on a numbered

display device. A thermocouple's output can be fed to the converter and the resultant

pulses used to trigger illuminated numerals.

When an analog quantity has been put in digital form for processing and storing,

it's often desirable to recover the information by using a digital-to-analog converter.

The automobile tachometer is an example. Engine revolutions - analog data - are

translated into digital form by the breaker points, which produce pulses used to

fire the sparkplugs. A DC meter is used to indicate engine rpm, but the meter can't

respond to pulses. It needs a DC voltage, furnished by the circuit of Fig. 5.

An input pulse causes C1 to charge through D1 with indicated polarity. While

this happens, D2 is reverse-biased and therefore nonconducting. After the pulse

has passed, the voltage on C1 reverse-biases D1 and discharges through D2 (which

is now forward-biased). C2 charges until the voltages across both capacitors are

equal. The next input pulse causes exactly the same sequence of events, adding more

voltage to C2. But meter resistance RM is in parallel with, and constantly

discharging, C2. As a result, the meter indicates the average voltage across C2.

The faster the engine turns, the more pulses per second are fed to the circuit,

the more quickly C2 is charged, and the higher the meter reads. Thus meter indication

is proportional to engine speed.

The preceding examples are employed in certain simple devices but have limited

application in industry and communications. More complex systems, combining several

functions. are used extensively for special applications.

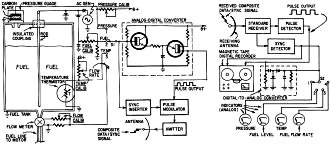

Figs. 6 and 7 are simplified diagrams of a telemetry system used to obtain fuel-tank

information from a rocket in flight. All values to be measured are analog, so the

sensing devices produce continuously varying output voltages, each proportional

to the parameter being measured. One important item is the rate of fuel flow. To

sample the flow, a paddle wheel in the fuel line drives the armature of a DC generator

(Fig. 6). Hence, the DC voltage is proportional to the rate of fuel flow.

It's also desirable to know how much fuel remains in the tank at any time. The

task is accomplished with an unusual capacitor. Again referring to Fig. 6, a rod

is suspended in the middle of the tank, forming one plate of the capacitor. The

walls of the tank form the other plate. The value of this capacitor is determined

by the dielectric constant of the liquid (which is known for each fuel type) and

by the amount of liquid in the tank.

Since the capacitance is very small, special techniques must be used to measure

any change. The tank capacitor is placed in series with an external fixed-value

capacitor, forming a voltage divider. An AC generator places a voltage across this

divider so that any change in the value of the tank capacitor changes the AC voltage

amplitude. This AC output is rectified to produce a DC voltage for further processing.

Resistive voltage dividers fed by DC sources are used to measure fuel temperature

and pressure. One divider contains a thermistor in the tank, monitoring the temperature

and varying DC output voltage proportionately. Fuel pressure is measured by a carbon

block between two metal plates in another voltage divider. Any increase in tank

pressure compresses the carbon material, altering the output voltage.

The output from each sensing device is tapped down to a convenient range for

conversion to digital form. It would be desirable to monitor all parameters continuously,

but only a single transmitting channel is available: consequently, time multiplexing

must be used. Switch S1 connects each sensor output to the converter for a short

period, then moves on to the next one.

The analog-to-digital converter operates just like the one shown in Fig. 4. Its

pulse output - which is proportional to the quantity being measured - is fed to

a pulse modulator. This stage modulates the transmitter of the rocket, which sends

the telemetry information to the receiving station. Note the sync inserter - this

device adds a sync signal to furnish a reference point for locating the position

of switch S1. Thus at the receiver it's possible to determine which quantity is

being measured at any time.

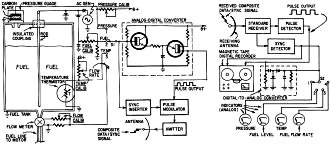

Fig. 7 shows how the telemetered information is processed by the receiver. RF is processed by a conventional methods, and a pulse detector recovers the original

pulses. These pulses go through the digital-to-analog converter, and the continuously

varying DC output is fed to sampler S2, identical to and synchronized with S1 in

the rocket. S2 feed analog data to the various indicating meters, which are calibrated

in gallons per second, pounds per square inch, etc.

For permanent reference, a tape recorder stores the pulse information. At any

later time, the tape may be played back and used to drive the converter, S2 and

the readout meters.

For greater resolution, sometimes the pulses are fed directly to electronic counters

with numerical display readouts. At other times the analog outputs of S2 are fed

to oscilloscopes or ink-chart recorders.

The system described in Figs. 6 and 7 is necessarily simplified; most systems

are more complicated and sophisticated. However, the same basic principles are employed

in both.

There are many other types of converters and sensors - time encoders, shaft-angle

decoders and weighted decoders. All accomplish similar tasks. A continuously varying

quantity is monitored by a sensor, the information changed to pulses, and these

pulses used to control some portion of a production process. For human monitoring

of the quantity, the pulses are converted back into continuously varying voltages,

where they drive meters.

Digital and analog systems are like two languages. The converters are really

translators. They're useful because two different systems can then exchange information.

It's a lot like two persons from different countries talking to each other through

an interpreter. Without him, there'd be no communication.

Posted April 11, 2023

|