|

June 1963 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

This "Which Dry Battery for

You" article is a follow-on from the previous month's "Dry Cell Battery Types"

in Radio-Electronics magazine. It was a time long before the dominance

of rechargeable lithium batteries. In 1963, battery-powered devices were nowhere

near as widespread and diverse as they are nowadays. Hand tools like drills, saws,

routers, planers, and screwdrivers got their power either from a wall outlet or

the user's arm and hand muscles. Lawn mowers, grass and hedge trimmers, chain saws,

and snow blowers were powered mostly by gasoline, although some models plugged into

the wall. Those devices which did use batteries most often had no built-in recharging

capability, and most cells were of the primary type and therefore were not rechargable.

The most prevalent type of rechargeable (secondary) battery was

nickel cadmium (NiCad).

NiCad cells have a lower energy storage density than today's more common nickel

metal hydride (NiMH) and lithium-ion (LiIon) or lithium polymer (LiPoly), and earlier

NiCads exhibited a significant "memory" characteristic which caused them to lose

capacity if left on a "trickle charge" or were constantly recharged after only a

partial discharge.

Which Dry Battery for You?

There is a best dry battery for every job. This article will help you pick it

out.

By Gordon E. Kaye*

Dry batteries are made in three common types, commonly called zinc-carbon, alkaline

and mercury. The zinc-carbon battery is further divided into four varieties. These

were described in the article "What Is A Dry Battery?" in the May, 1963, issue.

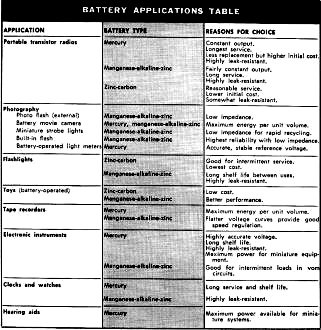

Each of these types has its own best applications, due to its composition or the

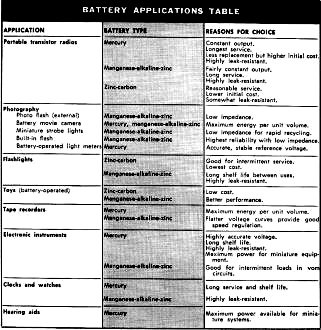

proportions of the elements used in its mix. The table illustrates some typical

consumer applications and the reasons for choosing correct battery types for them.

There are hundreds of other industrial, military and commercial devices using dry

batteries.

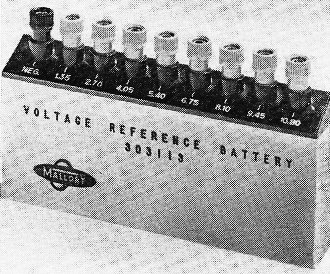

A rather special application is that of voltage standard. The industrial-grade

mercury battery may be used as a voltage-reference source. (Some varieties of mercury

cells made with a manganese dioxide blend are not suitable as a voltage reference.

The MnO2 causes a reading of 1.4 volts. This can be spotted easily.)

At intermittent drains up to 1 ma, it is within 1% of its original 1.357 volts for

a period of 2 to 10 years. Aged cells, after 3 years, can have a long-term stability

of 0.1 %.

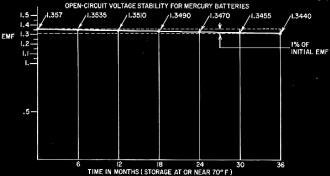

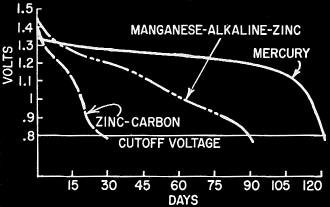

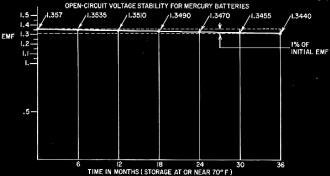

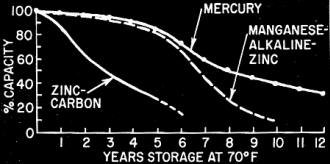

Fig. 1 - Chart shows excellent shelf-life of mercury cells

and batteries.

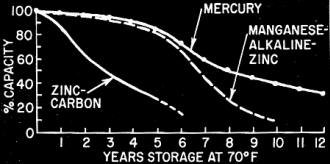

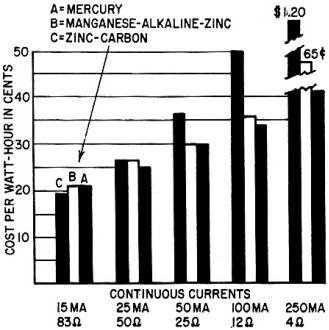

Fig. 2 - Expected shelf-life of the three battery systems

at 70° F. Storage at 120° F reduces shelf-life to one-fourth the values

shown.

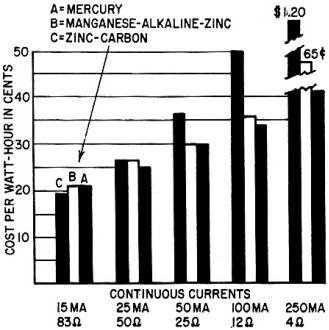

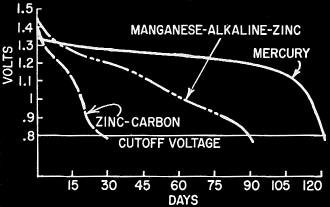

Fig. 3 - Comparative costs per watt-hour of the three battery

systems at different load levels.

Fig. 4 - Life-span of cells discharged into 60-ohm loads

for 8 hours per day at 70° F.

Fig. 5 - Comparative watt-hour per pound ratings of the three

primary cell systems.

Direct measurements may be made on these cells with ordinary voltmeters. Voltage

potentiometers are not needed, except where more precise readings are required and

calibration against a primary standard is called for. You can attain short-term

accuracies in the order of one part in a million, especially if the temperature

is a stable 120°F, and the cell has been aged. The average open-circuit voltage

of these cells doesn't seem to drift over the years, as shown in Fig. 1.

Selecting a Battery Type

The simplest economic viewpoint in dry-battery use is the cost of delivered energy

per hour (cost per watt-hour). Not so obvious is the inclusion of a shelf-life factor

(Fig. 2) as well as a quality-rating factor. The latter would be important in high-quality

appliances such as battery-operated tape recorders, cameras, wristwatches or light

meters. If equipment is left unused for a long time, leakage and loss of capacity

can raise battery operating costs. Equipment damage and undelivered energy are valid

charges against a cell system.

The chart in Fig. 3 compares the cost per watt-hour for the AA penlight cell

in the three dry-cell types. Various current rates are shown against costs, based

on list prices for top-grade cells. It can be seen that heavy loads raise energy

costs appreciably. There is an economical cell size for each application. Also,

the alkaline systems are less costly in heavy-duty, long continuous service, especially

where voltage levels are to remain high (Fig. 4). Shelf life and leakage factors

also tend to favor these systems.

Zinc-carbon cells and batteries are more economical initially, and are favorable

in lightly loaded, intermittent applications. They are less costly in the larger

cell sizes due to a higher efficiency when operating at nominal rates.

Battery Application Table

Watt-hour ratings per pound (Fig. 5) are decisive in many applications where

weight and bulk must be kept to a minimum. The dry-battery products manufactured

today represent the accumulation of 70 years of industrial electrochemical experience,

beginning with Leclanché and continuing right through to the advanced-design

mercury cell. The number of batteries required per product is reduced, battery efficiencies

are higher, and their operating costs are consequently lowered. An example of this

is seen in the compact, modern transistor radio.

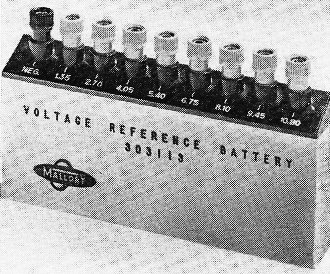

A 10.8-volt voltage-reference battery.

Selecting the right battery, how-ever, requires that you consider battery capabilities

in terms of application requirements. Regardless of the application, there is a

correct cell or battery design for maximum performance. The table and charts will,

we hope, assist you in your selection.

* Application engineer. Mallory Battery Co.

|