|

November 1959 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

I was very surprised to

find an example of a rather significant flexible printed circuit substrate in this

"Printed Circuits Are Here to Stay," article appearing in a 1959 issue of Radio-Electronics

magazine. That era was when much debate, particularly amongst service people, was

occurring regarding whether printed circuits would be a welcome replacement for

the previous point-to-point wiring method of connecting components and cables.

Proponents appreciated the neatness and compactness, while opponents didn't like

the lack of robustness and intolerance to heating and pulling off mounted

components. What

was even more interesting was the mention of a "Persister" element, that was

made by Ramo-Wooldridge - the "RW" part of "TRW" (Thompson Ramo

Wooldridge, which merged in 1958). A Web search on

persister turns up

only biological cells which resist antimicrobial treatments. This computer

persister worked at near absolute zero as a superconductor, and could switch in

"10 millimicroseconds" or in modern lingo 10 nanoseconds - not bad for 1959!

Printed Circuits Are Here to Stay

By Allan Lytel By Allan Lytel

Resistors, capacitors, switches - all printed on circuit boards that may be shaped

to suit the job - give electronic designers a new dimension to work in

From a modest beginning just a few years back, the uses for printed circuits

have grown until today when they are found in almost every type of electronic instrument.

They are used in satellites and missiles, in radio and TV receivers, and in computers

and industrial control systems.

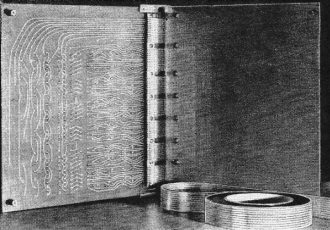

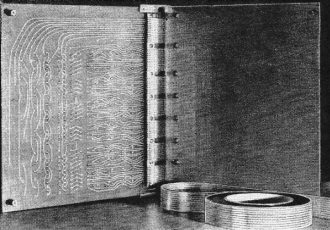

Fig. 1 - The chassis of this Stromberg-Carlson unit is in the

form of leaves in a book that arc interconnected by a flat mu multiconductor cable.

Fig. 2 - This circuit is printed on a flexible material.

Fig. 3 - The TA-11 (no longer in production) was a tiny four-stage

transistor amplifier.

Fig. 4 - High-speed low-temperature memory unit for electronic

computers. Production models of the device, called the Persister, will be approximately

a quarter the size shown.

Fig, 5 - A complex multiple-switch pattern with connecting leads

brought out to a plug connector.

Fig. 6 - The HEP switch.

Fig. 7 (left) - Two printed packaged radio circuits: a - Diode-pentode

coupling circuit; b- diode-triode coupling circuit.

Fig. 8 (right) - Three printed TV circuits: a - Horizontal afc circuit;

b - sync take-off circuit; c - vertical integrator.

Fig. 9 - Four packaged amplifier stages are used in a modern

hearing aid.

Fig. 10 - A group of printed-circuit boards with ceramic bases.

They are designed to withstand high temperatures.

These circuits take many forms and many are unusual. Stromberg-Carlson uses a

book type construction, shown in Fig. 1, where the "pages" of the book are printed-circuit

boards. They are interconnected by flat multiconductor cables so the unit opens

up for servicing and folds flat when in use. Saunders Associates uses a flexible

circuit which can be applied to curved surfaces. (see Fig. 2), Centralab made a

four-transistor amplifier (Fig. 3) in a package only a little over an inch long.

Only the input, output, volume control and battery are external.

Other types of printed circuits include ceramics for high-temperature use, plated

circuits for resistance to corrosion and wear, and miniaturized printed circuits

including built-in transistors.

Flush switches with very long operating lives at lower cost are in production.

They are plated with metals of greater wearing qualities than copper. Connectors

make it possible to remove circuit boards from equipment for testing and repair.

Connectors are usually molded and have from 6 to 44 connecting terminals on a single

strip. Contacts are made of phosphor bronze or beryllium copper. Some are gold plated

to prevent corrosion.

Cables for use with printed-circuit connectors are available. These are ribbons

of cable made from many flat copper conductors. Typical construction encases the

conductors in transparent polyester insulation.

Circuit packaging includes stacks of ceramic wafers, single laminated plastic

plug-in boards, and sandwiches of two single-faced boards with the components in

between.

Computer Memories

Large-scale data processing machines use electronic memory devices with small

magnetic cores for one form of data storage.

Printed circuits are appearing in some new forms for memory units in digital

computers. Ramo-Wooldridge has experimental printed units for high-speed low-temperature

use. Fig. 4 shows one of these units. It is about four times the size of the production

models. Known as a Persister, this printed memory unit operates at temperatures

of nearly absolute zero or -459.6° F and because of its superconductivity at

extremely low temperatures, it can perform computer switching operations in 10 millimicroseconds

or 1/100 microsecond.

Also, MIT has shown that it is possible to use printed wiring to connect the

small magnetic cores now used for memories. This interesting and highly specialized

type of printed circuit has been developed at the MIT Lincoln Laboratory as a three-dimensional

circuit of etched wiring which goes through holes in ferrite cores of memory planes.

The TX-2 computer stores 2.5 million binary digits in a 256 by 256 by 38 stack of

ferrite cores. The standard 64 by 64 core modular plane requires four insulated

wires which are threaded through each of 4,096 cores, having 0.050-inch diameter

holes.

The new technique uses collimated light to produce, in a single exposure, the

image of the complete wiring for a memory plane. With collimated light means the

pattern mask does not have to be in direct contact with the sensitized laminate

to produce a sharp image. The cores are mounted in holes in the base laminate. The

entire board is then coated with a plastic to hold the cores in place. The board

is then coated with copper, by electroplating. Wiring of the cores was arranged

to avoid crossovers. The finished wiring pattern extends through each of the cores

and connects to another pattern on the other face. The method is much faster than

current production methods for memory planes.

Printed Switches

Computer switches are only one type of switching. For lower speed switching,

printed switches are used. These may be ordinary printed wiring or flush wiring.

There are cost savings in complicated patterns made of printed wiring as compared

to other, older methods.

Switches, commutators and slip rings, especially in complex patterns, are a good

example of this. Many switches that would be impractical by any other method can

be made economically, even in small quantities, using printed-circuit techniques.

The circuit itself can often be combined with the switch contacts for still greater

savings. Silver, gold or nickel-rhodium platings provide low contact resistance

and long life. With careful design, a life of many millions of cycles is being obtained

from printed-circuit switches.

Fig. 5 illustrates a complex multiple group of switch patterns with a plug connector

having leads from the circuit switch segments. In regular printed wiring there are

dead segments between the contacts to prevent bouncing.

In flush circuits the etched wiring is forced into the laminate base after heating

the base material. Since the conductors and the base are in the same plane, the

moving contact can pass over the switch plate without bouncing. Aerovox has developed

a method of producing flush circuits using silver. Copper-foil switches are often

plated to extend their useful life.

A new type of switch is the HEP (Hartsock Etched Plate) (Allison Laboratories,

Inc.). It is made of a printed circuit, shown at the top of Fig. 6, and a contact

board shown beneath. As this contact board is rotated the spring contacts, by their

circular motion, do the switching. A cam is used to rotate this contact plate and

guide pins control the board movement.

Switches of this type offer simplified switching techniques for many applications.

In one example, with silver contacts touching rhodium plating, there was no appreciable

wear after 110,000 cycles of operation. Since only the contact plate is moved, very

little force is required for switching.

Circuits on Ceramic

Ceramic circuits have long been used for R-C networks. Printing resistors and

capacitors on ceramics goes back to the early beginnings of printed circuits.

Ceramic-based circuits were the first type in wide use. The proximity fuse, which

was a miniature transmitter and receiver mounted inside an artillery shell, called

for mass production of highly reliable circuits. For this purpose, the National

Bureau of Standards developed the printed circuit using a ceramic base. Silver paint

was used as the conducting medium and it had to be fired at between 900° and

1,400° to burn off the binder and fuse the silver into a highly conductive metallic

pattern.

Because of this high temperature, only a ceramic could be used as a base. Steatite

is a dense ceramic material that has great strength and hardness. It also has excellent

electrical properties which are not affected by high temperature and humidity. The

powder is molded or pressed into wafers with the required holes and notches. After

firing, at temperatures up to 2,400°F, the silver conductors are applied and

the wafer is again fired (this time at a lower temperature) to fix the liquid silver

into solid metallic conductors.

Electronic circuits printed on ceramic boards are finding increasing acceptance

with the growing use of printed wiring board chassis. Replacing many components

with one part saves solder joints and simplifies and reduces the size of circuit

boards. Also, one part instead of several parts reduces the number of automatic

insertion machines resulting in more flexibility in changing from one receiver to

another and a reduction in capital investment for the manufacturer.

In each design, circuit response is made to duplicate as exactly as possible

the response obtained from separate components. Important stray capacitances are

carefully reduced to an absolute minimum. The values and tolerances of the separate

components and a schematic showing the function of the circuit in the overall unit

give our engineers data for a mutually acceptable design.

Reproducibility in production is assured by using screen printing. Several patterns

are reproduced from the master negatives used for the original samples. Fig. 7 shows

two circuits used in radio receivers. One is a diode-pentode coupler and the other

a diode-triode coupler. Television receivers have other printed ceramic circuits.

Some are shown in Fig. 8 (a horizontal afc circuit, a sync takeoff and a vertical

integrator). Many other circuits are also available.

A natural extension of ceramic-based circuits with printed wiring, capacitors

and resistors is to add active elements to make a complete amplifier. Centralab

has combined the elements with a transistor. They end up with a single-stage amplifier

about the size of a pencil eraser. A group of these are used for a hearing aid as

in Fig. 9.

Circuits with ceramic bases are also being used to extend electronics to high-temperature

operation. Some of these special boards are shown in Fig. 10. Welding is used to

connect the wiring and components on boards for high-temperature applications.

Posted April 5, 2022

|

By Allan Lytel

By Allan Lytel