|

January 1954 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

This statement by Bruce

Richards is an absolute truism, especially regarding ultimate system performance:

"Transmission line lead-in is a necessary evil. The service technician should not

regard it lightly. The best antenna and the best receiver in the country may not

give satisfactory reception unless serious attention is paid to the connection between

them." Gauging from some of the reader-submitted questions over the years to

QST magazine columnists, a lot of people do not fully understand and/or appreciate

the significant role the transmission line between the antenna and transmitter/receiver

plays. Much more concern is expressed over loss of power out during transmission,

but few seem to consider how the received signal is impacted due to resistive and/or

mismatch losses in the transmission line. The minimum discernable signal (MDS) is

directly affected, dB for dB, by line loss, so minimizing loss is extremely important

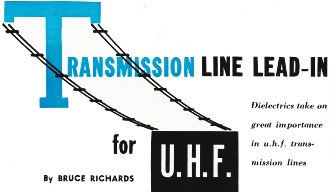

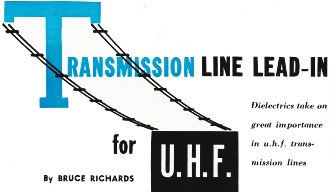

when you need to receive weak signals. Note in the Figure 1 graph how much

lower loss tubular type twin lead transmission line - which is not manufactured

anymore as far as I know - exhibits in wet conditions.

Transmission Line Lead-In for U.H.F.

Dielectrics take on great importance in u.h.f. transmission lines.

By Bruce Richards

Transmission line lead-in is a necessary evil. The service technician should

not regard it lightly. The best antenna and the best receiver in the country may

not give satisfactory reception unless serious attention is paid to the connection

between them.

There are no certain tests by which the service technician can determine which

is the best type transmission line lead-in. Any transmission line attenuates the

signal. Theoretically, the best transmission line is the one that couples the antenna

to the receiver with the smallest attenuation loss. The problems involved are different

for u.h.f. than for v.h.f. At ultra-high frequencies the losses are greater. A typical

attenuation curve is shown in Fig. 1.

We are going to present some of the fundamental principles of transmission line

cable for u.h.f. lead-in and will make comparisons between cables now on the market.

The attenuation losses for several types of line will be indicated. The effect of

weather on the lines will be indicated where data are available. See Fig. 2.

Nothing will be said about the effects of mismatch. Obviously, the more closely

matched the antenna, line, and receiver, the less will be the attenuation and other

mismatch losses.

Let's confine ourselves to three basic types of u.h.f. lead-in line: open wire,

ribbon, and tubular twin-lead cable.

Open-wire line

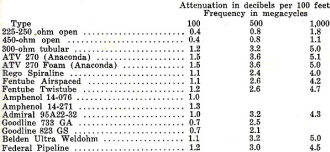

The open-wire line has a lower attenuation figure than other types. This attenuation

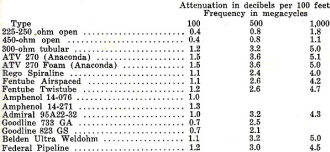

is approximately 1 db per 100 feet at the center of the u.h.f. spectrum. See Table

I.

Where it is necessary to run an exceptionally long. lead from antenna to receiver

this wire will hold to the low attenuation limit necessary for such an application.

Or, if it is possible to run a lead-in completely indoors so that it will be shielded

from weather, this is an ideal lead-in.

There are some disadvantages which make this wire a headache to the service technician.

It is difficult to mount, and it requires special care to avoid changing the spacing

of the wires between the insulators. Matching to a 300-ohm impedance is a serious

problem, because the characteristic impedance of open-wire line is 225-250, 375,

or 450 ohms.

A desirable characteristic of this type of line is that there is practically

no difference in its attenuation under wet or dry conditions. This is the only type

of line for which it can be said that if the picture is good under dry conditions,

the picture will be good under wet conditions.

Punched-ribbon line

Fig. 1 - Attenuation curve for an "air-spaced" two-conductor

oval cable. Courtesy Admiral Corp.

Fig. 2 - Comparison of transmission lines under wet and dry conditions.

Courtesy Admiral Corp.

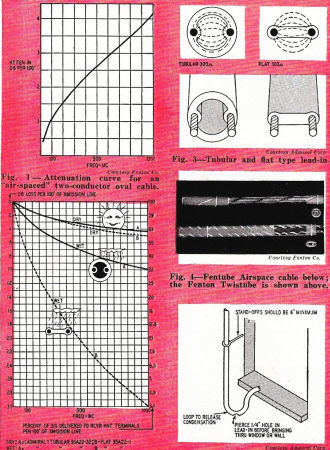

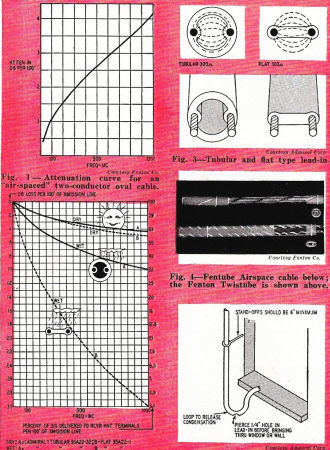

Fig. 3 - Tubular and flat type lead-in. Courtesy Fenton Co.

Fig. 4 Fentube Airspace cable below; the Fenton Twistube

is shown above. Courtesy Admiral Corp.

Fig. 5 - Diagram shows tubular transmission line lead-in at point

of entry.

Tests made under all types of weather conditions along seacoast sections have

shown that the average flat or round 300-ohm lead-in will give only a short period

of satisfactory service. The quality of the picture then deteriorates rapidly and

remains at a low level, as a result of the salt-spray deposits which encrust the

lead-in. Similar problems exist in areas where there is a hot, humid climate, where

much alternate rainfall and strong sunlight prevail, or where the lead-in is subject

to frost, snow, and ice.

One solution to this problem, which permits use of ribbon line for some locations,

is to punch out rectangles about an inch long and use short ribs to support the

wire at these inch intervals. This line has certain outstanding features. Eighty

percent of the loss-producing dielectric web is eliminated; the nominal 300-ohm

impedance is correct for a large number of receivers and antennas; it is lower in

cost than other lead-lines; and by insuring correct spacing of the flexible stranded

conductors, less than 1% of the operating wavelength is radiation loss.

Ordinarily, attenuation losses of unpunched twin-ribbon type lead are greater

than that of the punched-ribbon lead, except when water droplets accumulate in the

punched-out areas. The losses of punched lead are then very high; but this condition

disappears when the line dries out.

This punched type of line is good for an inside installation where it can be

kept clean and dry and would not be subject to the lossy effects of weathering.

Attenuation losses are moderate; it is flexible, easy to install; it fits into standard

insulators; and it does not present any impedance-matching problem.

Tubular cable

Each new advance in television brings along a number of accompanying advances

in associated products. The u.h.f. boom has encouraged the development of a large

variety of tubular-type twin lead-in cables. This is the type that is likely to

win general acceptance because it seems to provide the best over-all characteristics

for good u.h.f. reception under all conditions of installation, as well as with

aging and weathering. See Fig. 3. In tubular 300-ohm lead-in, the extremely important

field of energy is concentrated on the inside and is virtually unaffected by weather

conditions. In flat 300-ohm lead-in, the field of energy is largely outside, exposed

to all weather conditions and subject to signal loss.

The basic patents on putting two or more conductors inside a cable are over 50

years old. This means there is little room for invention in this field beyond minor

improvements. Hence manufacturers have been concerned with producing as good a wire

as possible with the lowest possible attenuation losses.

The published attenuation figures for a variety of these tubular twin cables

are in Table I. Some data were not available. For the most part these are laboratory

experimental data: what the data would be with respect to. actual reception of a

u.h.f. station is not known for the most part. This would be desirable information,

but it is not available.

Table I - Transmission Line Attenuation

All the u.h.f. receiver manufacturers usually purchase a number of·competing

types of cable, and, set up some experimental procedures to determine the performance

of the lead-in under ideal conditions, under wet conditions, and to determine results

of aging. These data become a company report and unless the information is released

the service technician, who would profit much from such information, is not likely

to see it.

The data on the Rego Spiraline given in this table were obtained under actual

test conditions of a u.h.f. station operating in the 700-mc region. Incidentally

this was the best performing tubular cable out of a group tested under dynamic conditions

in the metropolitan New York City area. This is a novel design twin-lead wire, using

a solid conductor. Let's look at it more closely.

Air is the most desirable dielectric for the twin-conductor cable now commonly

used for v.h.f. and for the tubular type cable being used for u.h.f. An ideal cable

would be a pair of air-supported twin conductors properly spaced inside a tubular,

cable. However, this can exist in theory only.

It is common to support the cables and to maintain them in their proper spacing

by means of a thin film of dielectric, sufficiently thick to serve the purpose of

maintaining uniform spacing. See Fig. 3, "tubular 300 ohm." The dielectric, by surrounding

the cable throughout its entire length, contributes markedly to attenuation losses,

since the highest energy field is in the straight-line path between the two. conductors,

Rego Spiraline has adopted a design featuring a thin wall of dielectric material

supporting the twin conductors at points such that the ratio of bare conductor to

dielectric-covered conductors is sufficient to permit maintaining uniform wire spacing

throughout the cable length and at the same time permitting most of the twin conductors

to be free of dielectric covering. The points at which the dielectric holds the

twin conductor to the wall of the tubular cable do not have to be opposite each

other; they may be staggered along the cable at alternate spots. The bottom cable

in Fig. 4 illustrates the design used by Spiraline.

This cable has low dielectric losses and superior characteristics under wet conditions.

This wire must be handled carefully during installation. Rough handling or sharp

bends will change the spacing of the bare conductors and affect the impedance characteristics

and attenuation losses of the wire. For the service technician who is very careful

in his workmanship, this is an ideal tubular type lead. The manufacturers have not

been pushing this wire because they don't know whether the service technician will

give it the installation care it requires.

Characteristic impedance

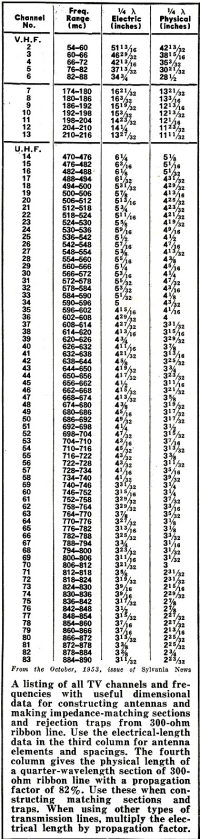

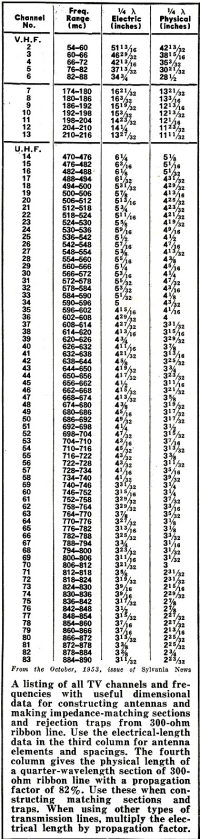

TV Channel Frequency Table

The characteristic impedance of a transmission line is important - more important

at u.h.f. than at v.h.f. because there is a relationship between the impedance of

a line and its attenuation losses. Both the size of the conductor and the spacing

of conductors affect the impedance of a transmission line. Standard tables of attenuation

losses show that losses are greater for lines with impedances less than 300 ohms,

For lines comparable in all other respects there would be greater losses fo a 280-ohm

line as compared to a 300-ohm line. Again, there is little the service technician

can do about this as the difference in spacing of conductors for 280 or 320 ohms

is negligible. Comparatively little wire is sold with a guaranteed impedance.

The spacing of the conductors varies from manufacturer to manufacturer for

a variety of reasons. Here are typical comments:

A. The spacing of the conductors was determined more by economic reasons than

any other. It was felt that it was best to keep the conductor spacing at the minimum

and so decrease the over-all size of the line, rather than get somewhat higher impedance

with a wider separation and therefore larger over-all dimensions.

B. The characteristic impedance of the flat and, tubular line is 300 ohms nominally

with a production tolerance of ± 20 ohms. For this reason it is possible

that the impedance could be 280 ohms and still be within tolerance.

Dielectric material

Most manufacturers advertise that their tubular cable is made with virgin polyethylene.

This may not always be true. Polyethylene is not available in the quantities necessary

to supply all demands by the wire and cable plants. Some of them are maintaining

production with a percentage or reused polyethylene. The Bakelite Company, manufacturer

of polyethylene, suggests, "The dielectric constant of reprocessed polyethylene,

we believe, is greater than that of new polyethylene due to the impurities which

are introduced either prior to or during the reprocessing operation. While we have

no data to substantiate our belief we do believe that reprocessed polyethylene attenuation

losses would increase more quickly with age due to impurities, as mentioned above,

which might be introduced either prior to or during the reprocessing operation."

Unfortunately there is little the service technician can do about such manufacturing

substitutions, as it is practically impossible to determine the difference between

virgin and reprocessed polyethylene. There is one clue which will help the service

technician get a good polyethylene wire. The smoothness of the finish on the tubular

twin-lead u.h.f. cable does influence the losses of the cable. If there is any roughness

on the outer surface of the polyethylene this rough portion would tend to catch

and be a collecting spot for dust, dirt, soot, and other foreign particles. Under

wet conditions this would tend to increase the losses for the cable involved.

Notes on tubular cable

Amphenol makes two types of tubular Twin-Lead cable: 14-076 and 14-271. The 14-076

is superior because of the following design and construction features:

1. The tubular design of the insulation reduces dirt and moisture concentration

in the field between the conductors. This means the impedance is constant for wet

or dry conditions.

2. 14-076 has seven strands of No. 26 wire as conductors rather than seven strands

of No. 28 wire as used in the 14-271 cable which has higher attenuation losses.

3. The design of the cable is such that there is a thin wall of dielectric covering

the wires and most of the field between the conductors is air. This is illustrated

in Figure 3.

The Fentube Airspaced tubular u.h.f. cable is illustrated in Fig. 4. This figure

also shows the Twistube. Both are made by the Fenton Company, New York City. For

most of the Fentube conductor length there is very little between the bare conductors

to interfere with the concentrated energy field. The No. 20 A WG conductors are

solid wires supported by means of the helical polyethylene wire-like cords.

The lines least affected by moisture and contamination are the new ATV-270 lines.

There are two types: the ATV-270 and the ATV-270 Foam. The Foam line is superior

at the high end of the u.h.f. band, because the attenuation losses are small. This

line uses two single solid conductors accurately spaced and firmly fixed in place

in foamed polyethylene. This line is so new there are no reports on it from field

tests as yet. These data are based upon the manufacturer's literature. The manufacturer,

Anaconda Wire and Cable Co., claims that attenuation characteristics for both types

of line are practically unaffected by moisture.

Installation

For new installations, 300-ohm flat line should be avoided for u.h.f., particularly

when long lengths must be used. There should be a minimum separation of 6 inches

from surrounding objects to prevent signal absorption losses. The standoffs should

keep the wire at least 6 inches from the building. Make a drainage loop in the line

just before it enters the house. Punch a hole at the bottom of the loop to remove

moisture condensation in the line (see Fig. 5). Avoid coils or kinks anywhere between

the antenna and the receiver. Cut the line to the proper size to reach the receiver

and do not leave any extra line which might be coiled up or kinked, causing impedance

changes.

Posted February 24, 2022

|