|

August 1966 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

When I saw this 1966

Radio-Electronics magazine article titled, "Vibration and Shock - Nature's Wrecking Crew,"

for some reason the first thing I thought of was "The Wrecking Crew,"

that anonymously played the music for a huge number of popular singers - mostly

those without prominent bands of their own (Sonny & Cher, The Mammas and the

Pappas, The 5th Dimension, Simon & Garfunkel, and others - see

video) - during the

1960s and 1970s rock-and-roll era. ...but I digress. My introduction to the

potential deleterious effects of vibration on electronics was in the 1970s, with

airborne receivers and servos in my radio controlled model airplanes. Even

though they were transistorized (vs. vacuum tube types from a couple decades

earlier), vibration from glow fuel internal combustion engines (ICE)

could wreak havoc with potentiometers in servos and solder joints

everywhere, including battery packs. I remember seeing the control surfaces

(rudder, elevator, ailerons) jitter as the servos driving them jittered at some

engine RPM points. Usually, packing the receiver and battery pack with foam, and

mounting the servos with rubber grommets under the mounting surfaces mitigated

the issue. A lot of R/C airplanes have bit the dust due to vibration problems.

The systems are much better nowadays, and a majority of models are powered by

brushless motors, so most vibration sources are gone. My next memorable

experience was with the mobile vacuum tube airport search and precision approach

radars I worked on in the USAF. Nearly every time we packed up the trailers and

convoyed them to a new location, upon setting back up and going operational we

would find failed tubes and/or tubes that had vibrated partly out of their

sockets. This article delves into methods and equipment used to investigate

vibration and shock effects on electronics.

Vibration and Shock - Nature's Wrecking Crew

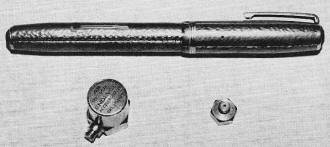

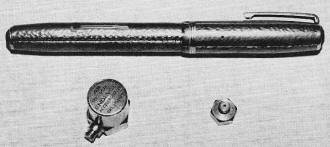

Fig. 1 - Two typical piezoelectric accelerometers. Most units

mount with studs or cement.

By William F. Kernin*

In controlled usage, vibration and shock are powerful and beneficial tools of

nature. If they are uncontrolled - all havoc breaks loose. The random shock forces

encountered by a ballistic missile, for example, exert tremendous loads on the electronic

circuitry packed inside the "bird." Combined with ever-present vibration fields

due to specific-impulse and frictional factors, these spurious effects do plenty

to shake up - sometimes even destroy - the "black boxes."

To investigate these forces and design electronic equipment to survive them,

the intensity and specific characteristics of the vibration and/or shock must be

defined. That is where the vibration pickup and its associated electronic instrumentation

play their roles. Let's examine typical equipment used to analyze these two very

similar effects and determine how we can use it to de-fine and catalog our twin

topics.

The most common device used to transform mechanical motion into an equivalent

electrical signal is the piezoelectric crystal accelerometer. Fig. 1 shows two general-purpose

devices suitable for many applications. Basically, a pickup of this type consists

of a piezoelectric crystal which is mechanically preloaded, using a spring-and-mass

arrangement. Any movement in the sensitive axis of the pickup causes a variation

in its electrical output. The signal obtained from the pickup is fed to a companion

amplifier by means of a low-noise, single-conductor shielded cable.

Various amplifiers with very high input impedance are available commercially

for use with crystal accelerometers. One type uses a modified cathode-follower input

stage to produce an input impedance variable from 100 to 1,000 megohms, depending

on the circuit design and the user's selection of resistor values.

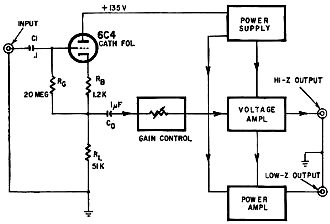

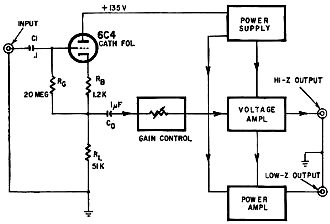

Fig. 2 shows a typical input stage and its associated amplifier circuitry. Because

input grid resistor RG is returned to ground through the cathode-load

resistor RL, the output-signal voltage is common to both input and output;

thus a large degree of feedback is obtained. The feedback level is great enough

to raise the input impedance from an expected value of 20 megohms, suggested by

RG, to a value of 200 megohms or higher. The actual impedance depends

on the value of grid resistor RG and the overall gain of the cathode

follower - a value always less than 1. As gain approaches 1, the input impedance

rises to a very high value. Very high input impedances are necessary because the

crystal accelerometer is a high-impedance voltage-producing device. It must be lightly

loaded to maintain its sensitivity and response to low frequencies.

Fig. 2 - Cathode follower provides very high input impedance

for accelerometer amplifier.

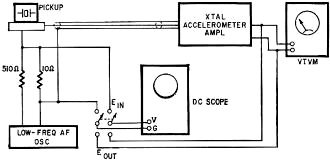

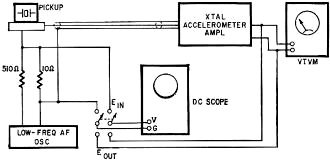

Fig. 3 - Setup for checking overall response. Scope or vtvm can

be used for measurements.

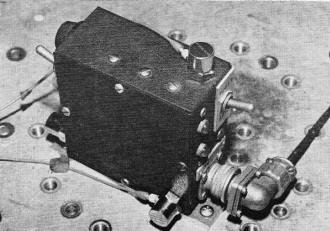

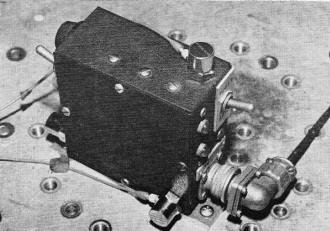

Fig. 4 - Vibration is checked in tree planes by pickups on top,

side and rear of equipment.

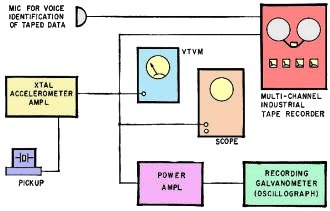

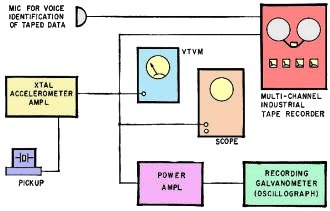

Fig. 5 - A typical instrumentation setup. Recorders preserve

records for later analysis.

Some of the equipment used to monitor and record vibration data.

Industrial recorder is on the left, seven-channel FM recording amplifier and meter

are in center. On the right is a dc oscilloscope and power supply. Pickup transducer

is at front of table.

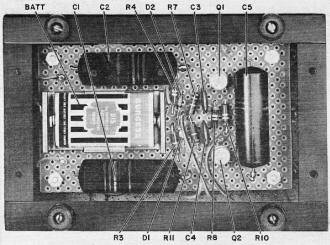

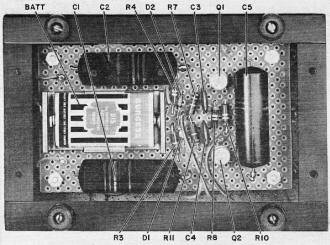

The simplicity of the scope switch is indicated in this under

chassis view.

A gain control and voltage amplifier follow the input stage, allowing low-level

signals to be boosted to a usable value. The output of this circuit then feeds indicating

instruments of somewhat lower impedances: an audio frequency vtvm, scope, or tape

recorder, for example. Also, this output can drive an additional power amplifier

that in turn drives a low-impedance recording galvanometer or other type of direct-writing

recording device.

To determine the frequency response of a cathode-follower/amplifier and its crystal

accelerometer - particularly at frequencies as low as 1 Hz or so - the setup shown

in Fig. 3 can be used. In this circuit, a 10Ω resistor is connected in series

with the pickup case. The combination feeds the input of the cathode-follower and

amplifier, feeding a nominal load. A low-frequency oscillator is connected across

the 10Ω resistor as shown, using a 510Ω series resistor. The dc scope

is used first to set the input level across the Ion load, then to measure the relative

output level for each frequency. Gain at 1 kHz is found first and used as a reference

level. Other frequencies can then be checked as desired to obtain a complete response

curve.

In a typical test setup used to measure environmental vibration levels, three

accelerometers are used - one for each plane (horizontal, vertical and lateral).

The pickups can be stud-mounted or cemented directly to the component under test.

In most cases, cement offers the best solution. Caulk Grip Cement - a dental product

- is a good, general-purpose adhesive that sets sufficiently strong for vibration

work in 30 minutes or so. For high-temperature work, as encountered on some points

of a rocket engine, Armstrong type A-1 adhesive may be used. Fig. 4 shows a typical

"black box" on which three accelerometers have been cemented prior to testing.

After mounting, each pickup is connected to its accelerometer amplifier through

low-loss cable. A small rubber washer on the connector helps prevent shaking loose

the cable. For high-humidity or altitude-chamber work, the connector is coated with

a liquid silicone rubber (General Electric RTV-20) that cures at room temperature.

When the test is over, the pliable rubber coating can be peeled off easily. As a

final precaution, the miniature cable from the pickup is taped down close to the

pickup and elsewhere along its length to prevent it from whipping around during

testing.

Depending on what use is to be made of the test signal, the output of each amplifier

can feed a scope, meter, tape-recorder channel, or recording oscillograph. Fig.

5 shows some equipment that may be used, singly or in combination.

Before a setup can provide meaningful data, the equipment must be calibrated,

beginning by finding the pickup sensitivity. For most purposes, vibration and shock

are measured in G's, one G being equivalent to normal gravitational force. The pickup

to be checked is mounted on a small shake table which will provide known variable

G forces. Its output is checked against that of a standard pickup - also mounted

on the table - at different frequencies. The sensitivity of the test pickup is then

expressed in millivolts rms per G peak.

Pickup sensitivity is affected by the characteristics of the cable connecting

it to its amplifier, by the amplifier's input capacitance, and by the pickup's internal

capacitance. Thus, complete calibration information may read like this for a typical

unit:

E (sensitivity) = 20 mV rms/G pk

C (pickup) = 900 pF

C (cable) = 87 pF (3 ft of cable)

C (amp input) = 23 pF

If, when setting up a test, a different length of cable is used, the pickup sensitivity

must be corrected using the following equation:

Thus, any convenient length of cable may be used and the calibration sensitivity

corrected correspondingly, as long as the cable capacitance and amplifier input

capacitance are known. The low-noise cables supplied with most pickups are normally

tagged with their total capacitance values.

Continuing our hypothetical calibration: If for a particular test the expected

level may reach ±10 G's, this suggests maximum possible signal of 10 x Erun

(200 mV rms, using the sample calibration data). Using an audio oscillator, a signal

of approximately 1 kHz is fed into the input of the accelerometer amplifier at the

expected 10-G level (200 mV rms). The amplifier gain control is then adjusted for

some convenient output value - 1 volt on a vtvm, 10 scale divisions on a scope,

the maximum acceptable input for a tape recorder, or 2-in. deflection on the recording

oscillograph. The system has then been calibrated so that a level of ±10

G's peak seen by the pickup will produce an easily read, known output. All pickup

channels are calibrated this way, and the system is ready to go.

There are any number of applications for an accelerometer system in the measurement

of vibration and shock levels. For example, the system can be used to obtain vibration

information from apparatus under actual operating conditions, as in the recording

of vibration levels on a rocket engine during hot-test firing. In actual tests of

this type, multi-channel tape recorders record highly varied vibration data ranging

from dc signals to high-frequency vibrations. A permanent record of the rocket test

run is obtained on tape, and it can be reduced, analyzed or transformed into any

form desired.

Vibration-Inducing Devices

After actual operating or environmental levels are determined, much vibration

testing is concerned with applying G forces to components, black boxes, and systems

at known levels to reveal any defects, or to quality the equipment.

A common instrument used for such testing is an electrodynamic vibration exciter.

This type of shaker consists of a massive driver - a voice-coil-driven table-field-coil

arrangement. It is powered by high-energy amplifiers or a controllable, variable-speed

motor-generator set. Equipment to be tested is mounted on the shaker head. Standard

pickups are then mounted on the device under test so that forces applied can be

recorded and used later for reference or evaluation.

A more elaborate type of shaker is the random-vibration machine. Instead of steady

frequencies, this instrument employs a band of frequencies with no definite repeatability

characteristics-random noise - to drive a specially designed shaker head through

powerful amplifiers. Failures often show up during random-noise tests that might

never be discovered in steady frequency tests. (See "Big Noise", Radio-Electronics,

Aug. 1963.)

Maintenance on vibration test equipment is basically a matter of common sense.

The pickup should be kept clean to afford good mechanical contact; the connector

must also be clean as possible. The miniature cables are tough, but no undue strains

or sharp bends should be allowed, especially at the connector ends. Avoid excessive

temperatures near the pickup. To shield a pickup from a nearby radiating heat source,

several layers of shiny aluminum foil have proved quite helpful as a rough reflective

cover. The cathode-follower/amplifier circuitry is not complex and can be serviced

with standard signal-tracing techniques when trouble develops. To insure optimum

operation and accuracy, the pickups and associated circuitry should be calibrated

as often as possible; once a month is considered adequate.

While the typical industrial electronics technician may seldom see much vibration

testing equipment, he should be aware of the basic principles and circuitry involved.

Not only may this information come in handy when he does encounter such devices,

but it may lead to further study and open new areas of new business through direct

contact with those actively engaged in vibration testing.

* Instrumentation technician, Engineering Labs, Bell Aerosystems Co., Division

of Bell Aerospace Corp., Buffalo, N.Y.

|