|

By 1950, says the author of this

Radio & Television News magazine story, "No longer are 'aerials' merely required to transfer electromagnetic energy

into space," in reference to airborne platforms." Following great advancements in

radio and radar technology during World War II, great interest lay in what

would later become referred to as 'stealth' technology and in secure communications.

The transition of aircraft speeds into the realm of supersonic also mandated that

projections beyond the main airframe outline be either eliminated or very much minimized.

The long cable aerials that stretched from the cockpit area to the tip of the vertical

fin, and the round direction finding antennas hanging from below could not be accommodated

at airspeeds above about 300 knots. The aerodynamic drag would be excessive

and the forces would tear the antennas apart. Douglas Aircraft set up one of the

first antenna measurement laboratories specifically to address those issues both

for airborne and shipboard platforms.

The Antenna Research Laboratory

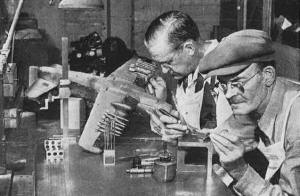

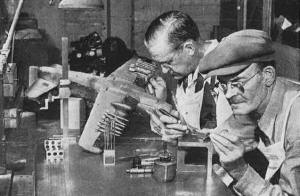

Fig. 1 - Tiny crystal receiver shown in engineer's right

hand, is used to detect signals from model antenna. Plate on side of model plane

is removable to permit receivers to be installed within the hollow fuselage of plane.

By Joseph M. Boyer, Consulting Engineer

Douglas Aircraft's laboratory eliminates costly full-scale experiments by using

tiny replicas in solving complicated antenna design problems.

Never before in the history of radio has interest in the antenna beam been at

such a feverish pitch! No longer are "aerials" merely required to transfer electromagnetic

energy into space. Experts today, working with surrealistic shapes of metal and

plastic, are molding radiated energy into the precisely shaped beams needed for

the varied classes of radar - for highly eavesdrop-proof communication links, or

even changing the beam's contour from instant-to-instant, automatically following

the boiling vagaries of the Heaviside layer.

The center of all such investigation is the antenna research laboratory. Here

antenna engineers work with worlds in miniature. Out on the model antenna range

of one such laboratory it is not uncommon to see a complete scale replica of a television

station: the tiny buildings, the accurately-made antenna towers, even the green

rolling hills of the surrounding country. This Lilliputian model slowly revolves

on a turntable, a large horn-type radiator some distance away "illuminating" it

with microwave signals. The miniature antennas of the model station detect such

energy and feed it back to high gain amplifiers in the laboratory. Thus, as the

model turns, automatic plotting instruments draw an accurate trace of the radiation

pattern of the station for later study. Such model tests save costly cut-and-try

procedures previously made on full scale installations.

Fig. 2 - Diagram shows position of model aircraft and rotation

axis for each of the three principal radiation pattern "cuts" made during pattern

study.

Even more important, in view of our National Preparedness Program, is the investigation

of aircraft antennas. With aircraft now operating both near and beyond the speed

of sound, no object of any kind is permitted to project from the sleek, polished

metal skin to add parasitic drag. This requirement is a death warrant for the numerous

masts and wires which once were draped lavishly over aircraft exteriors. In the

high-pressure search for distinctly new antenna types which may be faired flush

into the skin of a high speed airplane, several of the large airframe manufacturers

have aided the radio art immeasurably by taking the lead in such research. In order

to see, at first hand, the evolution of a new antenna, a visit was made to the El

Segundo, California antenna laboratory of the Douglas Aircraft Company which pioneered

in this field. Here, work begins with the presentation of the Navy specifications

to the aircraft antenna designer.

Such specifications call for a v.h.f. communications antenna. This unit is to

be mounted flush within the skin of a high speed carrier type fighter, yet provide

full 360-degree coverage about the horizon. When used for transmitting, the antenna

must produce most of its signal in a zone approximately twenty degrees above and

below the airplane. Efficiency must be equal to the older type protruding antenna

because airborne power requirements are stringent. Finally, as if to complete the

designer's frustration, such an antenna must be capable of operating from 300 to

5901 megacycles while remaining matched to the coaxial transmission line

feeding it. Specifically, it must not exceed a voltage standing wave ratio of 2

to 1.

The resourceful engineer begins a strenuous period of reading the available technical

literature, making rough preliminary calculations, and weighing and discarding a

number of configurations which come to mind. In this process the crude pencil sketches

which litter his desk would be unrecognizable to prewar engineers. There is not

a sign of wires or porcelain insulators. One sketch may show a small square portion

of the metal skin isolated from the surrounding surface and fed by a tapered funnel

section of coaxial line. Or perhaps a flat disc of polystyrene a foot or so in diameter

is shown, excited at its center by a sphere of silver designed to function as a

wide-band dipole.

Finally, the antenna designer may feel he has what is needed. Before he makes

a preliminary shop drawing he must refine his design. This step involves extremely

complex calculations. For some such problems he must discard his slide rule, set

up the equations he wishes solved, and pass them on to electronic or mechanical

computing machines. Satisfied that his "brain child" has a good chance of success,

the engineer authorizes the experimental shop to fabricate a full size antenna and

pass it on to the antenna laboratory for measurements.

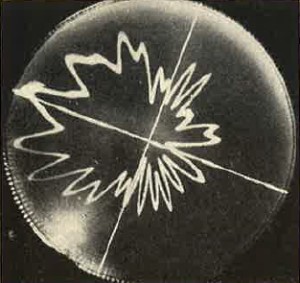

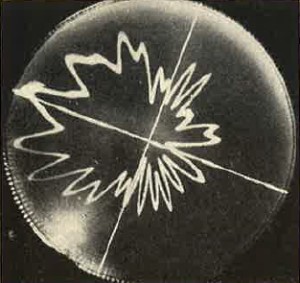

Fig. 3 - Typical aircraft antenna radiation pattern. The

pattern shown was photo. graphed on the screen of antenna range cathode-ray "pattern

painter." Magnetic deflection coils move in synchronization with rotation of model

under study, tracing out an accurate polar diagram of antenna signal variation around

the plane model.

Fig. 4 - Operating

and recording position. Shown are the v.h.f. and microwave transmitters, power supplies,

and switching panel. In front of operator is a pen recorder and the Douglas cathode-ray

"pattern painter." The "full moon" labeling device is seen as the white window below

the cathode-ray tube.

Fig. 5 - A coaxial slotted line in use. The slotted coaxial

line is used to measure the voltage standing wave ratio of the prototype antenna.

The radiator under test is mounted on the outside metal surface of the wall, directly

behind the Hewlett Packard Voltage Standing Wave Ratio meter shown in photo.

Impedance Measurements

The antenna laboratory technician, highly-trained and experienced in this specialized

field, first may mount the prototype antenna upon a large ground plane. This usually

is a metal wall forming one side or the roof of the laboratory building. In some

cases the antenna may actually be mounted into a full scale wire cloth mock-up of

the aircraft itself. A precision section of slotted coaxial transmission line (Fig.

5) is connected in series with the antenna and a laboratory v.h.f. oscillator. Beginning

at one end of the frequency range to be covered by the antenna, the technician makes

measurements of the voltage standing wave ratio in the transmission line. If the

antenna is a perfect match there will be no change in the measured voltage from

one end of the transmission line to the other. Such "flat" lines, however, are rarely

encountered. There usually is a small v.s.w.r, but it must be under the called-for

2:1 ratio. If the designer has done his job properly this condition will be met

over the entire frequency range desired. So far so good, but more hurdles remain

to be cleared.

Once more an order goes to the experimental model shop: "Fabricate one 1/20th

scale model of the antenna for range pattern tests." The men who receive this assignment

are not ordinary machinists or metalsmiths. They are, for the most part, former

instrument makers used to working with tiny precision parts under a powerful lens.

They are fantastically ingenious in devising ways of soldering and welding parts

the size of a pin head into place within complex assemblies, of bending and twisting

metal into shape while it is glowing in the flame of an alcohol lamp. An idea of

the difficulty of their job can be obtained when it is realized that ordinary RG

8/U coaxial cable reduced to 1/20th scale is the size of store string. The inner

conductor of such cable is the diameter of a human hair, yet must be soldered to

the minute antenna without melting an extremely thin, easily-destroyed polyethylene

sheath which insulates the assembly. Upon completing his exacting task, the model

shop craftsman places the tiny antenna into the metal skin of a previously prepared

1/20th scale model of the aircraft in which it is intended to see service.

Radiation Pattern Measurements

Briefly, the basic idea behind the use of the model antenna pattern range is

this: an aircraft operates far from the earth. The only environment which affects

the antenna on the airplane is the configuration of the craft itself. Any attempts

to measure radiation patterns on a full size aircraft resting on the earth would

be futile. Patterns taken by means of flight tests are not only prohibitively expensive,

difficult to measure and interpret, but usually end in doubtful results. However,

by reducing the aircraft to 1/20th or 1/40th of the full scale dimensions it is

possible to mount it from 40 to 60 wavelengths from the ground. This can be done

because the operating frequencies must also be multiplied by 20 or 40 to keep in

step with the model dimension change. That such theory is correct, when suitable

precautions are taken, has been demonstrated conclusively.

The scaled-down model aircraft, complete with its test antenna, is mounted upon

a special dielectric tower, the base of which rests on a motor-driven turntable.

Within the hollow belly of the little plane is a simple receiver usually consisting

of an impedance matching transformer and a silicon crystal detector or hot wire

bolometer.

With the tower placed as many as 100 wavelengths from the laboratory building,

technicians energize a tunable Klystron transmitter which excites a large horn type

antenna projecting toward the model through the wall of the laboratory. The transmitter's

signal is amplitude modulated by a square wave with a repetition rate of 1000 cycles.

A square wave is needed to avoid frequency modulation of the Klystron. Operating

frequency is carefully adjusted to be 20 or 40 times the full scale point in the

spectrum where the antenna is intended to function.

Reference to Fig. 2 will make clear the patterns to be described. The antenna

specialist refers to such patterns as "cuts." The first "cut" is made by slowly

rotating the model so that every portion of the plane's horizontal axis is exposed

to the radio beam from the laboratory transmitting horn antenna. The model on the

tower is then turned 90 degrees and again rotated by means of the turntable, exposing

its nose, belly, topside surface, and tail, to the beam. Finally, a "cut" is made

presenting the wingtips, belly, and topside surface of the model. This triad of

cuts - the horizontal, longitudinal vertical, and transverse vertical, are fundamental

in any pattern investigation and quickly tell if the radiation pattern of a new

antenna is going to meet specifications. At least the three patterns just described

must be made at frequent intervals over the simulated radio spectrum in which the

antenna is going to operate. An antenna may frequently have the desired radiation

pattern at one end of its frequency range and fail miserably at the opposite extreme.

Leaving the antenna designer for the moment with his problem let us enter the

laboratory building proper and investigate the equipment used to study the radiation

characteristics of antennas. Several racks of audio amplifiers are the first instruments

seen. These are quite special items. There are preamplifiers capable of boosting

the few millivolts or so of signal received from the model to about 10 or 20 volts.

This piece of equipment is linear in response and features a tuned feedback network

which permits the amplifier to operate with full gain only at 1000 cycles. All other

signals of random frequency and noise are sharply attenuated. The output of the

linear preamplifier drives a logarithmic amplifier which is also sharply tuned to

1000 cycles. Logarithmic response is desired so as to properly record variations

in the model signal which may extend over 50 decibels or more. To graphically present

the radiation pattern several different types of recorders are used.

Fig. 6 - General view of antenna model pattern range. A

scale model of the Douglas "Skyraider" is shown mounted on the motor driven dielectric

tower. The large electromagnetic horn antenna to the right is being turned to change

electric polarization of signal to model. Smaller horn to the left of the picture

covers the three centimeter frequency range.

Fig. 7 - Scale model aircraft and antenna shown in process

of construction. Craftsman in foreground solders a connection in minute cavity type

slot antenna. The 1/20th scale aircraft model shown is of wood.

The most common is a so-called polar recorder in which a pen is driven by signal

variations from the model through the use of a servo-mechanism. In appearance this

unit may resemble an automatic phonograph record changer. A circular piece of polar

graph paper is placed upon its turntable and centered by means of a pinpoint of

light at the center. The paper edges are clamped down by means of small Alnico magnets.

Rotation of the recorder turntable is synchronized by means of selsyns to turn in

step with the model out on the pattern range. When the model is rotated the servo-driven

pen moves back and forth on a radius, tracing out the pattern.

Also used is a cathode-ray pattern painter illustrated in Fig. 4. This instrument

has several important advantages over the pen type recorders. One of the most valuable

is lack of mechanical inertia. There are occasions when a radiation pattern being

recorded varies from a deep null to maximum signal intensity within a fraction of

a degree of rotation. Even for the slow speeds at which the model turns (3/4 to

1 r.p.m.) this condition requires the pen to whip over the graph paper at an exceptionally

fast rate. The consequent lack of response and "overshooting" of the pen distort

such patterns.

This difficulty is absent in the cathode-ray "pattern painter." Here the magnetic

deflection coils actually rotate about the neck of the cathode-ray tube in synchronism

with the model. Thus, as the signal intensity changes the electron beam can follow

the speediest variation with no time lag, no error. When used for radiation pattern

plotting the screen (long persistence) of the tube is photographed on 35 mm. film

for a permanent record (Fig. 3), Another fine feature of the particular model

developed at the Douglas laboratory is an edge-lighted Lucite disc seen in the illustration

mounted below the cathode-ray tube. This disc is called the "full moon" because

of its characteristic of glowing with evenly distributed white light. All pertinent

data such as frequency, aircraft type, and description of the "cut," is typed on

transparent gummed paper and this is then fixed over the face of the "full moon."

Easily photographed on the same film as the pattern, such a screen label feature

permits the laboratory to obtain a very complete, foolproof record of work in progress.

Frequency Coverage

Antenna laboratories must have transmitters available to cover enormous ranges

of frequencies. To see the reason why, let us assume that the full scale frequencies

of three antennas to be tested span the region 80 to 1600 megacycles. Not only must

oscillators be on hand for these exact frequencies but, in addition, if the model

range measurements are to be made at 1/20th scale, r.f. generators are required

for the simulated range 1600 to 32,000 megacycles. Spanning such an expanse of radio

territory calls for an imposing collection of coaxial cavity, and "butterfly" type

oscillators, many, many Klystron tuners as well as elaborate high-voltage regulated

power supplies and frequency measuring equipment of great accuracy. It is no wonder

that antenna engineers always ask for bar-gains in frequency coverage when shopping

for transmitters; otherwise such equipment would overflow the laboratory.

To cover the multitude of problems which trouble an antenna specialist's slumber

would be beyond the scope of this article. Some of the especially serious ones,

however, may be of interest. The first and worst of these is spurious reflected

signals. Exactly the same problem is faced by television service technicians in

the form of "ghosts." The aircraft model itself is, of course, placed carefully

"in the clear." Any posts, buildings, fences, or personnel in its vicinity would

reflect signals into the model as if they were secondary transmitters. Such reflections,

depending upon their instantaneous phase, either add or subtract in certain directions

from the true magnitude pattern of the model.

Fig. 8 - Close-up of 1 cm. transmitter and horn antenna.

A complete 30,000 mc. Klystron transmitter, cavity wavemeter, and high gain horn

radiator makes only a light handful of microwave equipment.

Fig. 9 - Slot antenna and cable. The size of a pair of 1/20th

scale slot antennas and miniature coaxial cable may be judged by comparison with

hand holding them.

Fig. 10 - View of computer showing vacuum tube bays. Mathematician

inspects plug board which inserts problem into the 1285 vacuum tube electronic computer

used to solve complex antenna equations. Such machines are now routine tools in

the search for new antenna designs and antenna improvements.

Fig. 11 - View of "feed" end of large horn type antenna.

Coaxial cable shown supplies v.h.f. energy to probe "feed" for the large horn type

"illuminating" antenna. Microwatts are precious, and technician carefully adjusts

the matching stub for the maximum obtainable signal.

The real villain of this story, however, is the ground or platform upon which the

antenna laboratory rests. "Splash" from this source is almost impossible to eliminate

completely. Great care is exercised in designing the large sectorial horn antennas

which "illuminate" the models so that just enough beam width with uniform phase

front is produced to cover the model with r.f. energy. Even though this precaution

lowers the magnitude of floor "splash" it does not completely remove it. Sometimes

low metal fences properly called detraction edges are placed on the model range

to deflect the "splash" signal into a harmless area. Placing these fences for each

frequency used (and sometimes as many as 200 "cuts" are made on a single model)

is more of an art than a science.

Another troublemaker is the small coaxial cable which conveys the detected signal

from the model down the tower to the laboratory. This is, of course, a metallic

conductor of many wavelengths projecting from the model. Pattern distortion will

be introduced by this cable, and only highly experienced personnel can minimize

this difficulty by judicious placement of the cable when setting the model up for

a "cut." To overcome this hazard some researchers have actually placed midget transmitters

inside the model aircraft. Battery power or an air-driven generator energized by

a high pressure hose are used, but the attendant cooling problems and frequency

drift due to lack of power supply regulation makes this technique a last resort

measure.

The problem of distance in wavelengths at the operating frequency between the

model under test and the "illuminating" horn antenna poses, at times, a nightmarish

enigma for the antenna worker. In order that an accurate radiation pattern be secured,

the model aircraft must sometimes be placed as many as 100 wavelengths from the

laboratory antenna, otherwise true "free space" conditions are not realized. Even

at the microwave frequencies 100 wavelengths may be a sizable distance physically.

Unfortunately, the power output of laboratory type Klystron tubes is only about

200 milliwatts for the region up to about 8000 mc. and 40 to 50 mw. for frequencies

above this. Sensitivity of the simple receivers used in the models is quite low

and, upon numerous occasions, the model simply cannot be placed at the required

distance and still secure sufficient signal to record a pattern. The model tower

must then be moved into the so-called "near zone" region and many hours spent in

calculations and educated guesses in order to replot the pattern to some degree

of accuracy. The uninitiated invariably suggest going to higher powered transmitters

such as radar pulsed units. When such suggestor, however, ponders over the problem

of building or purchasing the number of high power, room-size radars needed to cover

the frequencies called for, he soon realizes that a fairly large warehouse would

be needed to mount them for use.

Rejoining the antenna engineer it is found that his new antenna has successfully

completed its preliminary radiation pattern tests. While mildly jubilant he must

still subject his creation to an investigation to determine its response to cross-polarized

signals. Also he must investigate what effect additional structures, such as wing

mounted rockets or bombs, have on its pattern. The worried frown will remain on

his brow for some time to come as he follows the antenna through the intricate maze

of production decisions, cost analysis, and lastly the flight test which places

the final stamp of approval on his work.

While emphasis has been placed on the aircraft antenna because of its present

importance, it should be made clear that the laboratories of such institutions as

Ohio State University are carrying on programs of investigation into many other

aspects of the antenna problem. For example, in the study of land-based radio stations

scientists must content themselves not only with dimensional perfection with regard

to towers and buildings, but must also actually design the soil of these scale models

to have proper conductivity at the higher model frequencies in order that it simulate

the soil found in the region under study. The "guess and by-gosh" methods of the

past in making costly antenna installations are slowly giving way to exact knowledge.

Last but by no means least, Naval research centers are engaged in measuring the

radiation patterns of antennas mounted within the complex maze produced by a ship's

masts, cables, and other marine structure. As might be expected, Naval antenna designers

must take the sea into account when making their scaled-down ships for range tests.

To an electromagnetic wave a ship resting upon the sea appears to have an exact

mirror image directly beneath it. This can be duplicated on "the Naval antenna model

range by cutting a ship model off at its water line and resting it upon a large

sheet of metal. In lieu of this, two ship models are constructed, sawed off at the

water line, and one fastened upside down to the waterline of the other. The technique

of making the actual radiation pattern measurements is identical to that described

for aircraft.

1) Military frequencies are classified. Those given are only representative.

Posted April 25, 2023

(updated from original post

on 5/10/2013)

|