|

When this article on component

(resistor, capacitor, and inductor) measurement appeared in a 1957 issue of

Radio& TV News magazine, readily available,

inexpensive multimeters were not in existence. For about $20 you can now buy

a brand new handheld DMM that will make very accurate resistance measurements

and reasonably good capacitance measurements at frequencies up to a few MHz,

where lead inductance starts to be significant (test frequency is usually only

a few kHz). Finding an affordable, accurate inductance meter is another story.

Cheap

LCR meters can be purchased on Amazon

for around $35-$50, and the quality is supposedly very good. For $150-$200,

LCR meters are available the measure at

multiple frequencies and display the complex impedance (real and imaginary

parts). The most accurate measurement method uses a frequency in the

realm of actual operation, and this article presents methods that will allow

you to do just that by using typical bench top instruments.

Component Checking

By N. H. Crowhurst By N. H. Crowhurst

A discussion of various ways that circuit

components in radio and audio equipment can be checked without trouble.

Sometimes the simpler things one encounters in radio and audio work are apt

to get overlooked. For example, it would seem to be quite an easy matter to

check the inductance of a smoothing choke or the capacitance of an electrolytic

capacitor, with the correct polarizing current or voltage. However, when one

looks around to find a test instrument to make the measurement, it just isn't

readily available, so we are virtually forced into the routine of taking things

for granted.

If we wish to check as to whether a certain component is functioning correctly

or not, the only available method seems to be by substitution, using another

component of the same type. Often this proves to be somewhat unsatisfactory,

because the results can be inconclusive. We really need to know how to check

the various fundamental components used in radio: resistance, inductance, and

capacitance, to varying degrees of accuracy, ac-cording to their purpose.

Resistance Values

The simplest method of resistance checking is by means of a simple ohmmeter,

either an instrument built specifically for this purpose or an ohmmeter range

on a volt-ohm-milliammeter. Accuracy of this method of measuring resistance

rarely exceeds 10% and may not even be as good as this.

Assuming that the accuracy of the moving coil meter used for the instrument

is ±2% and that the resistors used in the instrument are accurate to ±1 %, the

accuracy of the instrument as a perfect comparator between the internal and

external resistances cannot be better than ±1%. And the accuracy of comparison

is only to within ±2% of the full-scale current reading on the scale. If the

scale reading, on a voltage or current scale, is compared with the reading on

the ohms scale, it will be found that an error representing 2% of full scale

in voltage or current reading may amount to an 8% error in resistance value.

This is at the point of maximum accuracy of comparison, between the external

resistance being measured and the internal resistance of the instrument.

Thus it is seen that the best accuracy obtainable using an instrument with

a ±2% movement and ±1 % internal resistance gives a guaranteed accuracy at center

scale reading of 9%. At readings between one-third and 3 times the resistance

value, which is the range one might expect to use before switching to the next

scale, the accuracy can reasonably be expected to stay within 10%. With an instrument

using lower accuracy components than those used for illustration, the accuracy

of the final reading in ohms will be considerably poorer than 10%.

From this it will be evident that an ohmmeter can only be used to make a

rough check as to whether a resistance is within the preferred value range for

which it is color coded - if it is of a ±10% or higher tolerance rating. To

check that the resistance is within ±10% of its rated value, the result is a

little doubtful and it is certainly impossible to rely on an ohmmeter reading

to check to a tolerance of ±5% or closer.

Although the ohmmeter readings cannot be trusted for checking to close tolerances,

it is possible to use an ohmmeter to check for reasonably good matching between

pairs of resistors, if this happens to be the requirement rather than close

precision in actual value.

As an example, in many push-pull amplifiers the resistors responsible for

controlling the gain in the two halves of the push-pull arrangement must be

closely matched to ensure balance. Production values may be specified to 5%

or even closer tolerances, to avoid the necessity of having to select matched

pairs, but the essential feature is that the value of the two corresponding

resistors shall be within a close tolerance of one another. It will not necessarily

matter if both of them are, say, 10% or 15% from their nominal rating, as long

as they are within 5% of each other. This the ohmmeter is reasonably capable

of checking, because it is quite possible to read an ohmmeter scale to within

5%. Since the question as to whether the reading is within 5% of its actual

value is unimportant in this particular application, the significance of the

reading does not matter as much as whether the two resistors which should be

matched give readings within 5% of one another.

For some applications, however, such as calibrated attenuators or instruments

for use in radio it is necessary to check resistor values to closer limits such

as 5%, 2%, or even 1%, as the case may require. In these circumstances it is

important that the value shall really be within the specified percentage of

its rated value. The only method of making a measurement that is satisfactory

for this purpose is to use a Wheatstone type bridge, using calibrated elements

whose accuracy is better than the required component accuracy.

For most radio purposes the Leeds & Northrup bridge used for telephone

line work is quite accurate enough. In using a bridge there are two things that

control the accuracy of the reading obtained: (1) the accuracy of the resistance

elements of the bridge itself, and careful attention to see, that contact resistance

does not contribute an appreciable fraction under any circumstances; and (2)

the sensitivity of the null detector.

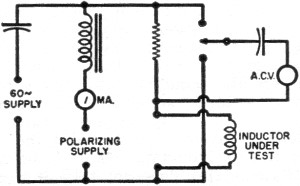

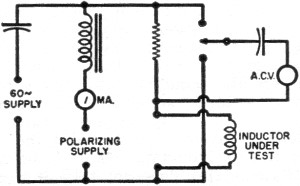

Fig. 1 - Bridge configurations for measuring inductance.

(A) the "Hay" bridge. (B) the "Maxwell" bridge. Relative advantages of each

type are discussed in the article.

Fig. 2 - Modification of the "Hay" bridge to enable

it to measure inductance with polarizing current flowing. Care is necessary

not to exceed the dissipation rating of the various bridge elements. See text.

Fig. 3 - A simple inductance checker circuit for determining

inductance with the polarizing current flowing in the component.

This second cause of inaccurate results can be checked by unbalancing the

bridge by a known percentage to see that an adequate off-balance reading is

obtained. Suppose, for example, the value required is 120,000 ohms, ±5%. Having

balanced the bridge and obtained a null at, say, 120,000 ohms, the resistance

in the calibrated arm should be altered by 5%, which represents a change of

6000 ohms.

If clicking in 6000 ohms additional in the calibrated arm shows appreciable

deflection, then the reading may be regarded as accurate; but if the addition

of 6000 ohms does not produce noticeable deflection from balance on the null

detector, the result is not reliable. To improve its reliability one can either

use a larger battery voltage or source of supply to the bridge, or else get

a more sensitive null indicator.

Before leaving this discussion of resistance values it should perhaps be

emphasized that it is not wise to put absolute trust in the color coding on

a resistor. Occasionally even the best resistor will be found incorrectly color

coded. If the error happens to be in the third color of the code, then the discrepancy

in resistance value will be a matter of shifting the decimal point which can

be quite serious. Also with some sets of coding colors the difference between

some of the colors is somewhat difficult to determine, especially after the

component has aged. For example, orange and brown can get to look quite alike.

Usually the first and second colors in the code can be identified by the

combination used, from the recognized preferred value range. If the first color

is blue, representing 6, the second color will most likely be either red, representing

2, or gray, representing 8, because 62 and 68 are the preferred values in the

60 to 70 range. But there is no such ready clue as to the likely color of the

third band: it could just as easily be brown or orange. Thus a resistor in which

this color looks at all doubtful could be either 620 ohms or 62,000 ohms, which

is a considerable difference!

This is where an ohmmeter check can easily determine which of the two values

is correct.

Inductance

Turning now to various kinds of inductance: the measurement of components

not intended for the passage of d.c. and without iron cores is a fairly simple

matter, with the aid of a conventional inductance bridge. Using such a bridge,

employing either the Hay or Maxwell configuration (see Fig. 1), the inductance

can be measured at a frequency suitable for the purpose, with a method quite

similar to the operation of a bridge for measuring resistance.

The principal difference is that two kinds of adjustment are usually necessary

to achieve null, because of the necessity for balancing the bridge in both amplitude

and phase. This enables the bridge to give a reading of both inductance value

and "Q" or loss factor. Bridges of this type are clearly marked to indicate

the correct setting of the controls for making each kind of measurement.

There is usually no difficulty in achieving a null with the air-core type

of coil, but if the inductance employs any kind of core, the null may not be

quite as definitive, because of the distortion of the injected test signal caused

by the core. Also, if the generator signal itself has any appreciable harmonic

content, a Hay bridge will never give a balance at both fundamental and harmonics

at the same setting. On the other hand, with an inductance where the only loss

is due to its resistance, such as occurs in an air-core coil, the Maxwell bridge

will give a fairly satisfactory balance for both fundamental and the lower harmonic

frequencies at the same setting.

When measuring an inductor that employs any kind of core to increase the

permeability, the magnetizing current is liable to distort so the inductor itself

will generate some harmonics not present in the input from the generator. When

the bridge is balanced to the fundamental generator input, there will be a residual

harmonic present at the null point, generated by the inductor itself.

This is a good reason for using ear-phones if the generator frequency is

in the audio range. Otherwise an oscilloscope with amplifier may be used as

a null detector. It is then possible, listening to the tone or looking at the

trace, to determine when the fundamental is balanced and the residue consists

of harmonics.

But the conventional type of bridge is only suitable for measuring inductances

where there is no polarizing current. The usual variety of smoothing filter

choke has to provide a specified inductance when polarizing current is flowing

and the inductance in the absence of such polarizing current will be considerably

higher than the rated inductance of the choke with polarizing current. Unfortunately

there is no simple fixed relationship between these two values.

If the choke has been designed to provide its maximum inductance at the polarizing

current for which it is designed, the air gap will be adjusted so that, at this

value of polarizing current, either reduction or increase of the air gap would

result in a reduction of inductance value. However, in the absence of polarizing

current, increasing the air gap will always reduce inductance value, while reducing

the air gap will always increase inductance value.

From this simple fact it is evident that measuring an inductance with no

polarizing current flowing is no criterion of its performance with polarizing

current. It can, of course, provide a check that the inductance is not completely

missing, due to short-circuited turns, in which case the inductance might not

even be adequate without polarizing current flowing. But the fact that the inductance

may measure twice its required value with polarizing current is no evidence

that the choke will give its rated value with polarizing current.

Fortunately, with filter chokes of this nature close tolerances are not too

important. Usually a compliance with a minimum inductance value will suffice.

It is sometimes possible to use a modified Hay bridge, as shown at Fig. 2,

to inject a polarizing current so as to measure the inductance with the polarizing

current flowing. But this can be a dangerous procedure, because the polarizing

current may exceed the wattage rating of some of the internal components of

the bridge and cause permanent injury to it. It is, therefore, better to devise

a simple checking arrangement, as shown schematically in Fig. 3.

This does not employ a bridge method, but checks the inductance by injecting

a known frequency and comparing the a.c. voltage developed across the inductor

with that across the resistor in series with it. The relation between the a.c.

components of voltage developed will enable the approximate inductance value

to be calculated. This does not take into account the effect of the inductor

distorting the waveform of the a.c. signal component, which invariably occurs

in this type of inductor and is, in fact, another reason why any attempt to

produce a precise figure of inductance will be somewhat meaningless. A rough

check of this nature is quite adequate for the purpose.

If 60 cycles is the supply frequency for the a.c. component, dividing the

calculated impedance of the inductor by 377 will give the inductance value.

For example, suppose the series resistor used is 100 ohms (carefully checked

in value), and the a.c. voltages measured across the resistor and inductor are

2 and 30 volts, respectively: then the impedance of the inductor at 60 cycles

is 1500 ohms, representing approximately 4 henrys.

Capacitance

Fig. 4 - The "Drysdale" bridge which is used for measuring

capacitance. Refer to text.

Fig. 5 - A simple bridge for capacitor checking that

forms the basis of a number of commercial units on the market. The null detector

is usually a "magic eye" tube.

Fig. 6 - Modification of a "Drysdale" bridge to permit

the measurement of electrolytic capacitors with polarizing voltage applied.

Fig. 7 - Modification of the simple bridge of Fig.

5 to enable polarizing voltage to be applied to the electrolytic capacitors.

For measuring all except electrolytic capacitors there are two methods, which

correspond in relative accuracy with the ohmmeter and bridge methods used for

measuring resistance.

The Drysdale bridge (see Fig. 4) is a modified Wheatstone bridge, in

which resistance arms are used in the ratio positions, while a calibrated decade

capacitor is substituted for the calibrated resistance in the variable standard

arm. This type of instrument can give capacitance results comparable to those

obtained with the Wheatstone or Leeds & Northrup bridge for resistance,

but its use involves careful adjustment of a number of controls until a null

is achieved.

The alternative method of capacitance measurement also uses a bridge, but

one in which the null is much more quickly achieved. In this bridge (see Fig. 5)

a standard capacitor is used in one arm, the unknown capacitor in another arm,

and a single potentiometer-type resistance for the other two arms. This resistance

is calibrated on the basis of the ratio between the unknown and standard capacitors

necessary to achieve null.

With this type of bridge the unknown capacitor is connected across the terminals

of the bridge and the one dial turned until null is indicated. The capacitance

value is then read off the dial. The accuracy of this type of instrument is

usually comparable to that of an ohmmeter, depending upon the accuracy with

which the potentiometer type resistance has been calibrated.

Neither of these methods is really satisfactory for the measurement of electrolytics.

This can better be understood by discussing a little further the behavior of

electrolytic capacitors under different conditions.

In the first place, electrolytic capacitors freshly formed ready for use,

have a dielectric film on the active plate of the correct thickness for the

working voltage. Under this condition the capacitor should have its rated capacitance.

But if the capacitor is operated consistently at a lower polarizing voltage,

the thickness of the formed film will gradually deteriorate with the result

that the effective capacitance will increase somewhat. This is not necessarily

detrimental to the performance of the capacitor, provided it is not subsequently

required for service at its nominal working voltage.

In much the same way electrolytic capacitors kept in storage also show a

deterioration in the dielectric film resulting in an increase in effective capacitance.

This means if a six-month-old capacitor is taken from the shelf and measured

on a regular capacitance bridge, without applying the necessary polarizing,

it will probably show a value considerably in excess of its nominal value. However,

it will not be satisfactory for operation until the electrolytic film has been

formed up to the requisite thickness for its working voltage.

This will have to be done with the aid of a limiting resistor connected in

series with the capacitor to limit the polarizing current while the film is

forming. Only when the film has formed up so the voltage appearing across the

capacitor is at its working value without excessive leakage current can its

capacitance be measured to give a reliable indication of its operating condition.

Also, if the capacitor is to be installed in a piece of equipment for operation

at its nominal working voltage, it is vital that this reforming of the capacitor

be performed before installation, so the capacitor does not take an abnormally

high leakage current when the power is switched on and possibly destroy itself

before it has had a chance to become correctly reformed.

The correct measurement of electrolytic capacitors with polarizing voltage

applied can be undertaken with either type of bridge, modified to a certain

extent, as shown in the schematics of Figs. 6 and 7. If the actual capacitance

value of an electrolytic capacitor is not vital, which often is the case, then

all that is necessary in installing a new one is to ensure that it is correctly

formed to its working voltage before connecting it in. This may be done with

the aid of the circuit shown in Fig. 8, which consists of a high resistance

feeding the capacitor with a voltmeter across it to indicate when working voltage

has been reached. The resistor limits the leakage current through the capacitor

to well within the maximum leakage current allowed, and when the capacitor has

reached its nominal charged voltage, it can then be removed from the charging

arrangement. Then, after discharging the capacitor for the sake of safety, the

capacitor is ready for installation in its intended circuit. Discharge should

preferably be accomplished through a fairly large resistor. The common practice

of short-circuiting a fully charged capacitor results in a very high discharge

current that may damage the capacitor.

Sometimes a capacitor which has been in stock a long time will deteriorate

in the quantity of electrolyte present, so the capacitance will fall low in

value, even after it has been adequately reformed.

Fig. 8 - Details for constructing a simple jig for

forming electrolytic capacitors up to their working voltage.

If it is not convenient to build a capacitance measuring arrangement incorporating

the polarizing supply, a fairly legitimate result can usually be achieved by

ensuring that the capacitor is correctly formed using the polarizing jig of

Fig. 8, then discharging the capacitor and finally measuring it immediately

with the aid of one of the conventional capacitance bridges without polarizing

voltage.

If the electrolytic capacitor is reasonably stable, a null will be obtained

which will not vary at a perceptible rate. If the capacitor is not sufficiently

stable to be reliable in use, the null may be observed to vary perceptibly while

the measurement is being taken. If the capacitance varies at a rate that can

be noticed while making the measurement, then the capacitor should be discarded

as insufficiently stable for reliable operation.

The foregoing discussion has covered the more common measurements necessary

on resistance, inductance, and capacitance. Sometimes much more precise methods

of measurement are necessary, especially where the equipment is for some kind

of standard operation such as a precision oscillator. In this kind of application

it is often necessary to make measurements, not only as to the precise value

at room or ambient temperature, but to determine the effect of temperature on

the component. To make such measurements, only precision bridge apparatus is

satisfactory, and the component should be measured under carefully controlled

conditions of temperature and the measurements repeated at different temperatures,

to discover what temperature coefficient the component possesses. Fig. 8.

Details for constructing a simple jig for forming electrolytic capacitors up

to their working voltage. See article.

|