|

Considering that only three-and-a-half

decades had passed since the brothers Wright first flew their eponymous "Flyer" off the sands of

Kitty Hawk, North Carolina, it is pretty impressive to think that by 1938 the

majority of commercial air transport planes were under the able control of electromechanical

apparatus(es?). Rudder, elevator, aileron, and throttle, driven by electrical

servomechanisms rather than human hands and feet, responded to the signals to

analog computers fed data from onboard barometer, accelerometer, level, and

compass sensors, and from ground-based radio directional beams. That was for

mostly straight and level flight from one fixed waypoint to another. An ability

to program vectored flight paths came later. This "Radio Lands the Plane" article

discusses progress being made in the realm of completely automated landings.

As can be seen, the framework for modern instrument landings systems was being

laid. Nowadays inertial navigation and GPS do much of the work and with much

greater precision and reliability. Just as with self-driving cars and semi rigs,

plans are afoot for self-flying aircraft. Will "they" get there in my lifetime?

I doubt it, but greater miracles have happened.

With the new radio control described here, planes can land without pilots

touching the controls.

Left to right: Capts. O. J. Cram and G. V. Hallowman, and

R. K. Stout, civilian engineer, who developed the Air Corps automatic landing

system, before plane used in tests.

By Harry Wilkin Perry, East Orange. N. J.

Transport airplane operation never could have reached its present status

without the aid of radio. Radio beacons guide the planes over land and sea when

earth and sky are blotted out by clouds or fog. Unerringly they lead the air

clippers over seemingly endless miles of ocean where navigation is difficult

even in clear weather because of drift, speed, and motion of the plane which

interfere with celestial observations and precise calculations.

Two-way communication between airports and planes in flight bring the pilots

frequent weather reports, landing and take-off orders that prevent collisions

in the air, and other information pertinent to flight operation.

Pilots of a fully-equipped transport plane have eighty or more instruments

and controls to watch and to operate. These impose mental strain and physical

fatigue, particularly in bad weather, that are inimical to safety; hence the

pilots have insistently asked for simplification of control. When thick fog

or a heavy snowstorm blankets an airport, flights are cancelled because of the

hazard involved in manual control under such conditions.

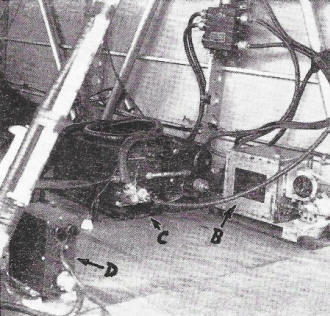

1 - Radio compass (C) connected with relay (B) and beacon

receptor (D) locks directional gyro.

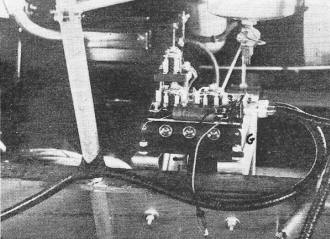

2 - Beacon receptor (D) and frequency selector (E) sets

the frequency of radio compass; operates altitude control (A).

3 - The frequency selector indicator (F) shows the correctness

of the automatic settings of the radio compass (C, Fig. 1).

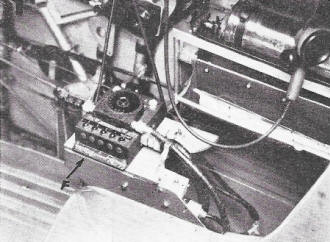

4 - The throttle control (G) is operated by the frequency

changes, controlling the throttle, and reducing speed.

5 - Landing switch (1) and auxiliary reset switches (2,

3, 4, 5) provide for hooking radio control into the mechanical pilot.

Diagram of ground antenna system showing Z-type marker beacons

operating on different frequencies which transmit the signals that actuate

the automatic landing apparatus.

These facts led to the beginning (three years ago) of development work to

simplify landing under bad conditions by making it automatic. This has now been

accomplished with notable success. Many excellent landings have been made under

a variety of conditions without the human pilot touching the controls. The method

was made possible by a combination of radio and a robot pilot. Full details

of the equipment are unavailable at present, as the apparatus is still undergoing

development and has not yet reached the commercial stage and application on

regular transport planes, though it probably will be in use in the near future.

However, already three-quarters of the mileage (in level flight only) flown

by airline transports is now done with robots in control of the planes. These

mechanical pilots automatically operate rudder, ailerons, and flippers to keep

the plane on course at the required altitude, and laterally balanced. They maintain

more accurate and smoother flight than human pilots do, particularly in bumpy,

gusty air, and relieve the latter of much tiring mental and physical effort.

Twenty-two airlines, comprising most of the principal ones in the world, are

using these automatic pilots on approximately 1000 airplanes in service in this

country and abroad.

Automatic landing, however, requires much more than maintenance of direction

and level flight, and it relies almost wholly upon radio. Two different experimental

methods are employed, one by the Army Air Corps at Wright Field, Dayton, Ohio,

and the other by United Air Lines Transport Corporation. Both utilize radio

transmitting equipment at the airport and receiving equipment in the airplane

in combination with the mechanical pilot. The method employed by the Air Corps

is entirely automatic, with direct connection between the radio equipment and

the automatic pilot, while that used by the airline involves manual adjustment

of the robot control knobs to follow radio indications down to a landing.

The Air Corps system employs a series of Z-type radio range beacons located

at intervals in line with the axis of the runway and extending for a distance

of about five miles from the port, as in Fig. 6. Each range beacon emits waves

on a frequency different from the others. In the airplane is a radio compass

(C in Fig. 1), which receives the directional signals from the airport and is

connected with a relay (B in Fig. 1) that interlocks it with the directional

gyro to keep the plane headed directly for the port. A range beacon receptor

D adjacent to relay B, and a frequency selector (E in Fig. 2) working in conjunction,

automatically set the frequency of compass (C) as the plane passes successively

over each range beacon and operates an altitude-control device (A). Correctness

of the automatic settings is indicated on a frequency-selector indicator (F

in Fig. 3).

When the airplane arrives within twenty miles, or less, of the airport, the

human pilot places it at a selected altitude and closes a master landing switch.

The altitude is then maintained automatically by the mechanical pilot, and if

the plane is not headed directly for the port, the heading is altered automatically

so that it flies in the direction of the radio landing beacon. Upon reaching

that beacon, the frequency of the compass is automatically changed by the receptor

and the selector to the frequency of the next inner beacon, and so on to the

final marker landing beacon whereupon the plane comes in to a gentle landing.

These successive frequency changes actuate a throttle control (G in Fig.

4) which responds to partly close the throttle of the airplane engine, thus

reducing speed for the landing glide. This throttle control is interconnected

with the altitude control so that the minimum height necessary for automatic

landing is maintained throughout the glide. Each successive beacon actuates

the throttle to control the angle of glide and the rate of descent until ground

contact is made.

Finally, switches on the landing gear are connected with the throttle control.

When the wheels are set down on the runway, they operate the switches automatically

and cause the throttle of the airplane engine to close so the engine will idle

and also simultaneously set the wheel brakes to bring the plane to a stop.

It was, of course, necessary to make some addition to the mechanical pilot

to provide for these automatic controls by radio. In the cockpit installation

(Fig. 5) the mechanical pilot is shown at J, the master landing switch at 1,

and the auxiliary reset switches at 2 to 5.

It is not necessary with this system that the airplane be headed directly

for the runway when approaching the airport, since the equipment will bring

it into line automatically even if it should be headed directly away from the

port. Many landings have been made without trouble in cross winds up to 11 miles

per hour and in moderately rough air conditions.

Several hundred smooth, precise landings have been made with the bent-beam

system used by United Air Lines, which employs two radio beams emitted from

the airport. A special transmitter sends out 93,000 kc. waves along the runway

in a directional beam theoretically 5-feet wide at the landing point and 100-feet

wide at the field boundary. Another transmitter operating on the same wave length

emits a bent beam directed along the runway and gradually rising from the landing

point to a height of 60 feet at the edge of the field, thus following the normal

glide angle of the plane. [See Lauding Blind, Radio News, July, 1935.-Ed.]

The airplane carries a special antenna to receive the directional and the

landing impulses, which are led to a special instrument on the panel to operate

a horizontal and a vertical needle. The vertical needle indicates position of

the plane with respect to direction of the runway, while the horizontal needle

shows its angle of glide in the landing beam.

Both beams are intercepted five miles or more from the airport at an altitude

of 2000 feet, and when the two needles indicate that the plane is headed directly

for the runway and is at the correct height in the landing beam, the pilot throttles

down the engine for a speed of about 80 m.p.h. and turns control over to the

mechanical pilot. The plane then follows the landing beam on a glide that starts

on a considerable angle and gradually flattens out to bring the plane to an

easy, level landing near the approach end of the runway. When the tail wheel

settles to the surface, the brakes are applied manually by the pilot. During

the glide, the pilot watches the two needles and if either shows a deviation

from course or angle, he adjusts regulating knobs on the mechanical pilot to

correct the direction and angle of flight. Except for these adjustments, the

landing is done entirely by radio and the robot pilot, the latter operating

the controls of the airplane.

An almost irresistible impulse inclines the human pilot to take a hand in

the operation when making automatic landings, but experience has shown that

more accurate and easier landings are made by the combination of radio and robot

without any human interference.

Posted January 21, 2021

|