|

Prior to the advent of thyristors

and semiconductor lamp and motor control circuits, a relatively simple and safe

- although heavy and bulky - method for controlling AC voltage was with the use

of saturable core transformer arrangements. By using a DC winding to control the saturation level of the transformer

core material, the inductance, and therefore inductive reactance, of secondary windings

can be controlled. Doing so has the same effect as using a

Variac that uses mechanical control

of the coupling and transformer voltage input/out ratio. The method shown here has

a potentiometer for adjusting the DC current level, but, as the author mentions,

electronic control circuits were/are also widely used. Prior to the advent of thyristors

and semiconductor lamp and motor control circuits, a relatively simple and safe

- although heavy and bulky - method for controlling AC voltage was with the use

of saturable core transformer arrangements. By using a DC winding to control the saturation level of the transformer

core material, the inductance, and therefore inductive reactance, of secondary windings

can be controlled. Doing so has the same effect as using a

Variac that uses mechanical control

of the coupling and transformer voltage input/out ratio. The method shown here has

a potentiometer for adjusting the DC current level, but, as the author mentions,

electronic control circuits were/are also widely used.

Saturable Reactors

By Erwin Levey

Details on a saturable reactor that can be quickly

assembled using two standard power transformers. Details on a saturable reactor that can be quickly

assembled using two standard power transformers.

The operating principles of saturable reactors have been known for quite a long

time, but it is only within the past few years that these units have come into general

use. Considering the reactor's versatility, the number of ways in which it can be

used is almost unlimited. Basically it is a magnetic device which functions as a

variable inductance. It has a d.c. winding which is used for control and an a.c.

winding which is connected in series with the load to be controlled. There is no

direct connection between the two circuits, the only linkage is through the magnetic

properties of the core on which they are both wound.

Operation is based on the phenomenon that the permeability of a magnetic material

is not constant. It varies with the strength of the magnetizing force applied. Since

the inductance of a coil is directly proportional to the permeability of its core

material, it also will vary. When the d.c. control current is zero the permeability

of the core is extremely high, therefore the inductance of the a.c. coils is large.

Since they are connected in series with the load the load current is extremely low.

As the d.c. control current is increased the magnetizing force through the core

is increased. This causes the permeability and therefore the inductance of the a.c.

coils to decrease. This, in turn, means that the load current will also increase.

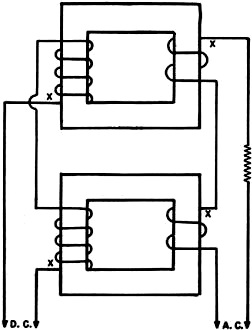

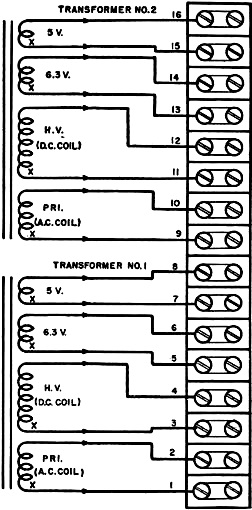

Fig. 1. - Terminal connections of saturable reactor using

two separate transformer cores.

As the d.c. current increases further the inductance is proportionately decreased

with a corresponding increase in load current. When the core is fully saturated

with full d.c. current the inductance of the a.c. coils is minimum. Therefore it

can be seen that the control effect is secured by means of d.c. core saturation.

Since the d.c. power required for control is less than the a.c. power used in the

load circuit the unit has a certain amount of gain or amplification.

Physically a saturable reactor has the same general type of construction as a

transformer although several different types of core arrangements are possible.

The one described here is extremely simple and is assembled by using only two standard

transformers.

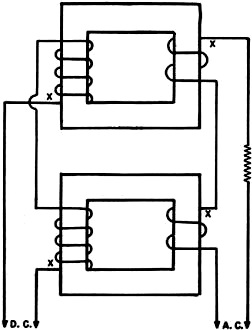

Fig. 5 is a photograph of a unit which was assembled breadboard style for

ease of construction. The two small transformers on the left are used as the saturable

reactor, the small motor being the controlled unit. The chassis on the right is

the variable d.c. power supply used for control purposes. Fig. 4 gives a close-up

of the reactor unit alone, from which it can be seen that the transformer windings

are connected to a screw-type terminal strip. This procedure facilitates connections

and requires only a screwdriver for assembly.

Before proceeding further, several terms which identify multiple coil connections

will be explained in order to clarify the main explanation to follow. In a "series-aiding"

connection two coils are connected together so that their relative winding directions

are the same. The net result is that the voltage induced in each is in the same

direction, while the total terminal voltage equals the sum of the two individual

voltages. In a "series-opposing" connection the two coils are connected so that

the relative winding directions are opposite, producing voltages in opposite directions.

Here the total terminal voltage is equal to the difference of the two individual

voltages. It is important to note that these relative winding directions are given

from an electrical viewpoint, and not in terms of the actual physical windings as

they are placed on the core.

Terminals of similar polarity or winding direction are indicated by means of

an X. This end is called the "start," the other end is the "finish." The conventions

that will be used throughout this article are illustrated in Fig. 3, which

also shows the proper type of parallel connection. To avoid confusion they are defined

specifically at this point.

As pointed out earlier in the article several different types of core arrangements

are possible. The one which will be explained here as the basis for the unit to

be constructed is the simplest type from an experimental viewpoint. A schematic

of the unit is shown in Fig. 1.

Two separate, identical cores are used, each having a d.c. and an a.c. winding.

Both a.c. windings are identical, so are both d.c. windings. However, the d.c. windings

differ in physical characteristics from the a.c. windings. Since each d.c. coil

is on a core with an a.c. winding there will be an a.c. voltage induced in the d.c.

windings due to transformer action. Now, if the two d.c. coils are connected in

series-opposing, the a.c. voltage induced in each will cancel, as a result of their

being equal in magnitude but opposite in polarity. This is the only permissible

connection for the d.c. coils. But the series-aiding connection for the a.c. coils,

as shown in the diagram, is only one of the possible connections for them. The unit

to be described here is based on this type of arrangement, as explained before.

For this purpose, two identical 40 ma. power transformers were used, each having

the following windings: primary (117 v.), high voltage (480 v.), 5 v. filament,

and 6.3 v. filament. All the secondaries had center taps but they were taped up

since they were not used. Actually, for the construction of a simple unit only the

primary and high voltage windings are needed but the low voltage windings can be

used to show some further interesting control possibilities. The primary is used

as the a.c. coil and the high voltage winding as the d.c. coil.

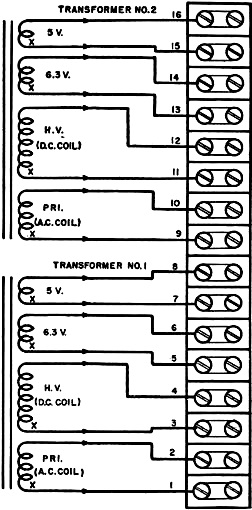

Fig. 2. - Transformer winding connections.

Fig. 3. - Coil connections. (A) series-aiding. (B) series-opposing.

and (C) parallel.

Once the transformers and terminal strips have been mounted the windings are

connected in the following order: primary, high voltage, 6.3 v. filament, and 5

v. filament. The order is the same for each transformer. At this point actual physical

order of the two leads of a particular winding do not matter.

The next and most important step is to properly phase .all the windings, that

is, to determine their winding directions with respect to the primary as the standard.

The procedure will be explained first for transformer #1 separately. Since the primary

is used as the starting point the connection to the first terminal is called the

start, the second connection, the finish.

Connect the finish of the primary to the high voltage lead immediately adjacent

to it. Then connect the primary leads to 117 volts and read the voltage appearing

across the two coils which are now in series. If the reading is the sum of the two

individual voltages the coils are connected in series-aiding, this being the condition

desired and indicating that the high voltage leads are in the proper physical order.

On the other hand, if the difference of the two voltages is indicated, the connection

is series-opposing. If this is the case, reverse the positions of the high voltage

leads and repeat the test. The reading will then indicate a series-aiding connection.

For each set of winding leads, the first one in physical order should be the start;

the second, the finish. If low voltage windings are present repeat the procedure

exactly as described using the primary and each winding individually. The complete

procedure should be repeated step-by-step for the windings of transformer #2.

The purpose of this test can be seen by referring to the schematic diagram in.

Fig. 2. The windings are laid out in standard order to facilitate the actual

interconnection of the units as a saturable reactor. This is the most crucial step

in the whole procedure and a double check should be made to make sure that no errors

exist. Otherwise the unit will either operate improperly or not at all.

As explained previously, the d.c. coils (high voltage windings) must be connected

in series-opposing. Following the original definition this is done by connecting

the finish of high voltage #1 to the finish of high voltage #2. The d.c. voltage

source is then connected to the two remaining leads, which are the start of high

voltage #1 and high voltage #2. In this simple arrangement the unit is not polarity

sensitive, that is, the positive lead could be connected to either end. However,

to keep a standard procedure (necessary for later arrangements), start high voltage

#1 will be designated the plus terminal and start high voltage #2 the negative terminal.

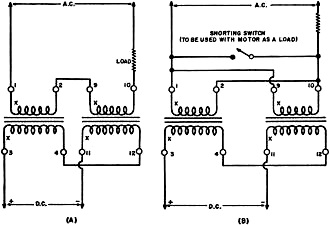

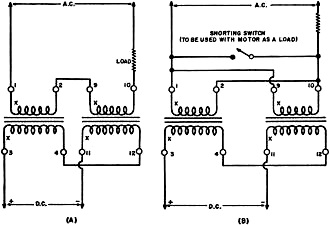

Next, the two a.c. coils (primaries) are to be connected in series-aiding. Therefore

connect finish of primary #1 to start of primary #2. These coils are then connected

in series with the load to be controlled. The actual schematic of this set-up is

shown in Fig. 6A.

At this point it is necessary to determine the range of the unit. The size of

the wire in the primary windings (a.c. coils) is determined by the power (actually

current) used under actual load conditions for which the transformer was originally

designed. This is done in the following manner: Total secondary power equals power

of each individual winding.

The assumption will be made that this is the same as ·the input power. This is

not exactly true in the case of an actual transformer but it is found that the assumption

is close enough to give an idea of the range, which is all that is necessary. Thus

it is shown that 40 watts is the limit due to the physical properties of the unit.

The actual amount of power that can be controlled is somewhat less, approximately

30 watts. From experimental results it was found that the d.c. current necessary

for complete control when the high voltage windings are used as the d.c. coils was

equal to the current rating of the high voltage windings plus 10% of that amount,

in this particular case, 44 ma. The unit used for control was a regular variable

power supply rated at 300 volts with no load. It is best to use a light bulb of

the proper wattage as the load so that the control effects can be observed visually.

When all the connections have been made, with the d.c. power off, plug in. the

a.c. load circuit. At this point the bulb will be either completely extinguished

or else very dim. Now turn on the d.c. power supply and slowly increase the current.

The brightness of the bulb will increase in proportion to the current, reaching

its maximum brightness at approximately 44 ma.

When the core is fully saturated at full d.c. current and the bulb is at its

maximum brightness it will be found that the voltage appearing across the bulb is

less than the actual line voltage (approximately 100 v.). This is due to the fact

that the reactance of the coils cannot be decreased to exactly zero. As a result

there will always be some drop across the reactor. In commercial applications this

is corrected by providing a supply voltage which is about 5% higher than the normal

operating voltage of the controlled unit.

Fig. 4. - Close-up of reactor. Two small transformers are

used.

Fig. 5. - Breadboard assembly of saturable reactor motor

control.

At the other extreme it will be found that the lamp voltage does not drop to

zero, since the reactor cannot be infinite in value. This of course means that the

load current cannot be decreased to exactly zero. However in the case of a lamp

load it will "black-out" at approximately 15% of full line voltage. When a resistive

load is used the two voltages, across the reactor and across the resistive load,

are 90 degrees out-of-phase. When the load is also reactive, for example a motor,

the voltages will be in-phase. The net result of all this is a slight reduction

in the control range.

In the next arrangement the two a.c. coils will be connected in parallel. Again

following standard convention the finish of primaries #1 and #2 are connected together

and the start of these same windings are connected together. The start ends are

connected to the a.c. line and the finish ends are connected to the light bulb and

then to the other side of the line (coils in series with load unit). The d.c. coil

connections are not changed. The actual schematic of this circuit is shown in Fig. 6B.

When using this connection it will be found that the d.c. control current needed

is only one-half of that required for a series connection of the a.c. coils. It

will also be found that the unit will operate much more efficiently in this arrangement.

This results from the fact that the primaries were originally designed to operate

on 117 volts.

If desired, a small fractional horsepower motor can be substituted for the light

bulb. Its power rating must be approximately the same as the light bulb used. For

this purpose, the type of motor used in

Erector Sets or small movie projectors is the proper size, but

it must be a 117 volt a.c. type.

It is necessary to observe certain precautions, because when a motor first starts

it draws an excessive line current which is higher than its normal value at full

speed, with the consequent danger of overloading the unit. To avoid this a shorting

switch is connected across the a.c. coils so that full line voltage can be applied

to the motor. Once the motor is started the switch is opened, changing the control

of the motor to the saturable reactor.

Fig.6. - Saturable reactor with a.c. coils connected in series

(A) and in parallel (B).

In order to simplify specific arrangements and procedure the foregoing explanation

has been based on the ratings of a 40 ma. power transformer. However, units have

been built using 70 ma., 90 ma., and 150 ma. transformers and the system is exactly

the same when any of these are used.

The gain of the unit can be calculated by the following formula:

gain = output power (a.c.) / input power (d.c.)

The gain of the small unit is relatively low, but as the size of the unit is

increased the efficiency also increases which means that the gain is higher. The

cores used are made of 4% silicon steel which operate best at high power levels.

Manual control has been used in this presentation to avoid complications. There

are several very interesting ways in which these units can be controlled by means

of regular electron tubes.

In the beginning of this article it was pointed out that a multiple control unit

can be made by making use of the low voltage windings, making possible control based

on multiple input signals. Once the unit is assembled it is merely necessary to

connect the proper type of control unit to each set of windings. Since the windings

are different from the high voltage windings the control conditions are entirely

different. Therefore it would be necessary to experiment in order to determine the

best control conditions for each of the various voltage windings.

Posted April 7, 2023

(updated from original post on 6/27/2016)

|

Details on a saturable reactor that can be quickly

assembled using two standard power transformers.

Details on a saturable reactor that can be quickly

assembled using two standard power transformers.