|

October 1957 Radio & TV News

[Table

of Contents] [Table

of Contents]

Wax nostalgic about and learn from the history of early

electronics. See articles from

Radio & Television News, published 1919-1959. All copyrights hereby

acknowledged.

|

Sure, you do it all the time,

but at some point either someone probably suggested to you and/or showed you how to clip substitute

components into a circuit in place of a suspected bad component while troubleshooting

or maybe during the design or tuning process. Miniature circuits of today pretty

much rule out using alligator clips to patch in a part, but sometimes it is possible

to use miniature "J" clip leads or even pin probes to make the connection long enough

to take a measurement. Since I do a fair amount of circuit work on other-than-RF

applications, I often find myself using short insulated, stranded wires with mini

alligator clips on each end to make connections. This "Substitution Jigs Speed Service"

article from a 1957 issue of Radio & TV News magazine has a few tips

for you.

Substitution Jigs Speed Service

By B. Van Sutphin

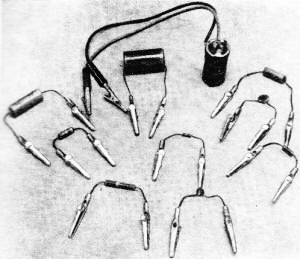

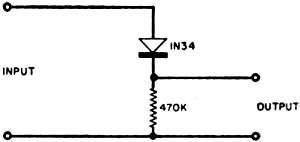

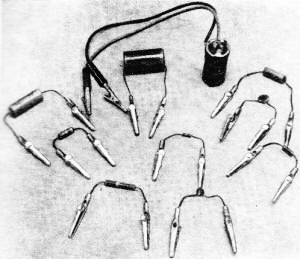

Fig.1 - Common, single-component jigs used in service, referred to in text.

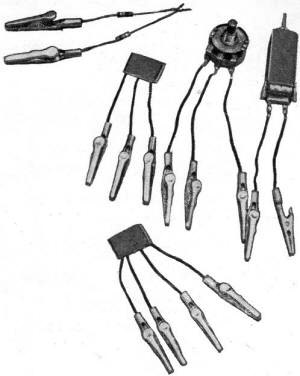

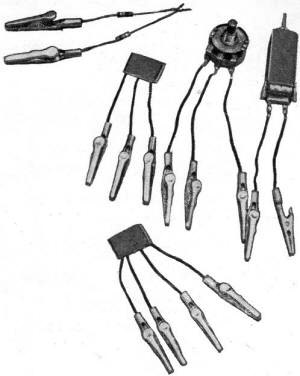

Fig. 2 - Clip leads can also be fixed to elaborate components such as potentiometers, i.f. cans, printed circuits.

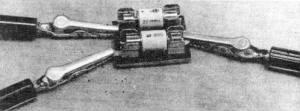

Fig. 3 - Two silicon rectifiers in holder can be hooked up in half-wave,

full-wave, doubler, or other configurations for power-supply tests.

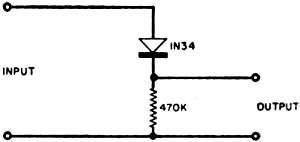

Fig. 4 - This detector jig provides an audio signal from a modulated generator

which does not have a separate audio jack.

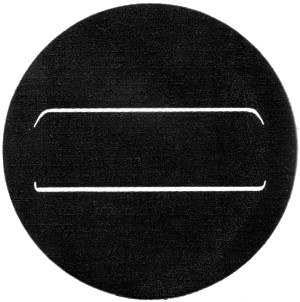

Fig. 5 - Trace of flat band of a sweep generator, taken through detector

probe.

The use of clip leads for temporary test hook-ups can be extended to provide

even more time-saving.

In the service shop, the accent must be on convenience and speed. If time can

be saved, that means more income per hour of work.

Most shops keep a collection of clip leads for temporary connections to speaker

voice coils, phono motors, and other points. These are simply lengths of insulated

wire with alligator clips at each end. In addition, special jigs are often made

up for connection problems that come up again and again. Typical examples are jigs

to fit the speaker sockets of popular auto radios with leads to connect to the shop

test speaker and special jigs for feeding the sweep-generator output to a TV receiver.

This idea can be extended even further. Fig. 1 shows some single-part jigs

convenient in radio and TV servicing. Included are two common filter capacitors,

a special-value 1000-volt capacitor for testing in damper circuits, a general-purpose

600-volt test capacitor, two resistors of common value, and three low-value ceramic

capacitors for general-purpose testing. Although not shown in Fig. 1, a video-detector

diode jig is also convenient. The units shown are constructed by adding alligator

clips to each end of the individual parts. For maximum safety, insulated clips can

be used if they are available.

With a collection of these aids, part substitution is simply a matter of connecting

two clips. This system is much safer than trying to hold a part in place while watching

a TV screen and it is much simpler than "tacking" new parts in place with solder.

Think of the ease of substituting new parts when the customer asks for a quick estimate!

In most cases, substitution can be made by clipping the replacement directly

across the suspected part. Of course, this does not apply when the suspected defect

is a short in the original part. In those cases, you would have to disconnect one

side of the original part and then clip the new one in place, but even here some

time is saved.

As shown in Fig. 2, this idea can be carried further yet. Clips can be mounted

on potentiometers, i.f. transformers, and even complete printed circuits, provided

there are not too many leads. The "can" shown in Fig. 2 is a 4.5-megacycle

sound take-off coil common in many receivers. The printed circuit with three leads

is a vertical integrator network, complete with built-in blocking capacitor (Centralab

PC-101). The blocking capacitor is important so that the network can be used in

more receivers - this one can replace the original network whether it uses a blocking

capacitor or not, and whether it is a printed circuit or uses separate components.

In Fig. 2, the printed circuit with four leads is a complete network for

coupling the plate of a triode audio amplifier to the grid of an output stage.

If a number of these printed-circuit jigs are used, it is a good idea to draw

the schematic of each one on heavy paper and then paste it to the side of the printed

circuit. Use ink for drawing the schematic, and then coat the drawing with spray

plastic to protect it.

The twin-resistor jig at the upper left-hand portion of Fig. 2 is a pair

of 100,000-ohm resistors in series. This is for insertion in discriminator or ratio-detector

circuits during alignment. This is much simpler than soldering individual resistors

in place each time. "

The block-like device in Fig. 3 is a pair of silicon rectifiers (Sarkes

Tarzian M-500) in a standard holder. This unit can be used as a single half-wave

rectifier, a high-voltage half-wave rectifier (two rectifiers in series, useful

up to 260 volts), or as a two-section rectifier in a voltage doubler. It can be

used for temporary substitution in new sets using silicon rectifiers or in older

sets that originally used selenium rectifiers, whenever it becomes necessary, in

receivers of this type, to make checks on the operation of the power supply.

Fig. 4 shows a detector circuit for obtaining an audio signal from a signal

generator that does not have an audio output jack. Only two parts are used: a 1N34

crystal diode and a 470,000-ohm resistor. The unit is constructed just like the

twin-resistor jig shown in Fig. 2. Connect the signal-generator output to"

the input of the detector, set the signal generator to any convenient frequency,

and the audio signal will appear across the 470,000-ohm resistor. This audio signal

can then be fed to the circuit under test. Its strength can, be adjusted with the

r.f. attenuator on the signal generator.

A similar unit using a 1N82 high-frequency diode "and a 4700-ohm resistor is

handy for checking the outputof a sweep generator to be sure that it is reasonably

constant over a particular range. If the sweep generator does not have a terminating

resistor at the output of its cable, connect one having a resistance value equal

to the characteristic impedance of the output cable. This will prevent standing

waves from appearing because of possible impedance mismatching. Connect the sweep-generator

output to the detector input, and connect the scope input to the detector output

of the generator.

If the sweep-generator output is constant over the particular range, the trace

on the scope will be similar to that shown in Fig. 5. Any humps or dips in

the trace indicate that the sweep generator output is not constant over the range.

(Incidentally, it is well to check the detector on various ranges first with a sweep

generator known to have constant output. This is to prevent possible resonance effects

in the detector circuit from giving misleading results. This is particularly important

on the higher TV channels.)

The jigs described here are those the author has found most useful. Other service

technicians may think up their own to fit particular problems that come up again

and again. Technicians doing warranty work on a specific line of equipment will

probably find special units with parts that frequently fail very useful. Almost

any part can be put in a jig like this. Perhaps the only exceptions are parts used

in high-frequency circuits. For example, substitution of a new diode in a u.h.f.

converter circuit cannot be done this way. You still have to clip the leads and

solder the part in place.

Posted March 9, 2022

(updated from original post on 8/28/2014)

|