|

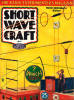

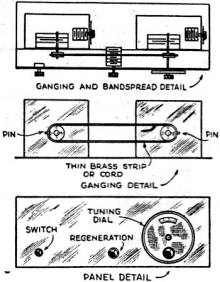

Band Spread Trick

I am submitting a short-wave kink which I have found truly practical and

very efficient. It is a band-spread kink which is truly automatic and which

changes condensers when the different plug-in coils ale inserted. This system

is really very flexible and may be varied to suit the fancy of the builder.

Connections of the secondaries and ticklers are shown for five different bands:

C is regeneration condenser, .00025 mf.; C1, a condenser to spread 20- and

40-meter bands; C2 will spread the 80- and ten-meter band; C3 covers the broadcast

band. - Wm. Porter.

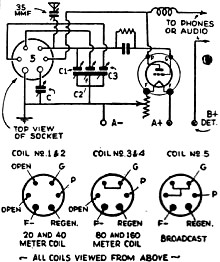

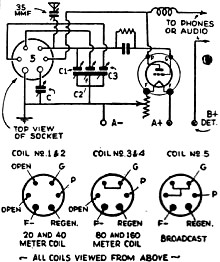

Magnetizing Stunt

Many experimenters have had occasion to need a tool which has been magnetized

in order to retrieve screws, nuts, or washers which have been dropped in the

process of assembling radio apparatus. The drawing shows how a screwdriver

or similar implement may be magnetized by bringing it in contact with the

"pole-piece" of a dynamic speaker. Of course the speaker must be running in

order that it will be magnetized. This stunt will only work of course on iron

or steel tools and it will attract only like metal. Brass, copper, or aluminum

will not be attracted to the magnetized screwdriver, of course. - Luther Burkhardt.

Handy Lead-In Insulator

If a suitable lead-in insulator is not on hand, one can be constructed

from a pair of regular stand-off insulators by the following method: Remove

the fittings from two of these insulators and procure a length of 3/16-inch

threaded brass or copper rod, 4 1/2-inch fiber washers, 6 nuts to fix the

rod and a length of 1/2-inch glass tubing; also make two rubber washers 3

inches in diameter with a. 3/4-inch center hole. These can be cut from an

old inner tube. I am using a pair of these insulators for bringing in a transposed

lead-in and I find them very satisfactory. - John Schlener, Jr.

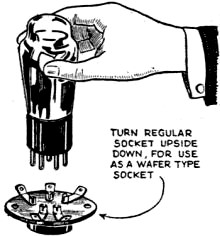

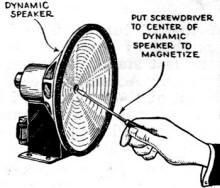

Homemade Coil Form

When making plug-in coils, especially the ones with larger windings,

I found that the usual tube base was too short, In the drawing it can be seen

that two tube bases are used; by removing the pins of one and cementing it

in the top of the other, we have a very neat coil form.

It is necessary, however, to wind the required number of turns on the lower

coil form before the two forms are cemented together. Then wind the other

form and run the two ends of the wire down through the holes which were left

when the prongs were cut off. The drawing clearly shows how the entire unit

is assembled. - Milton Sarchett.

|

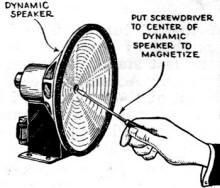

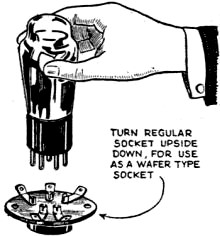

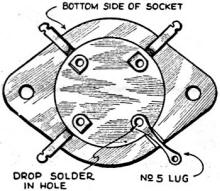

Inverted Socket

There are many times when I have found that a socket could not be mounted

in the way it was designed for, and have found that it was possible to turn

it up-side-down and overcome the difficulty. A sub-panel socket or wafer socket

can be turned up-side-down and mounted on top of the panel as shown in the

drawing. Of course, all sockets, due to their peculiar contact construction

will not work this way. However, I have found that 90% of them will. I have

also found that the base-mounting socket could be mounted underneath the sub-panel

by replacing the screws which hold the contact and face them downward. - S.

Javna.

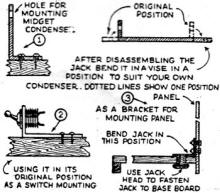

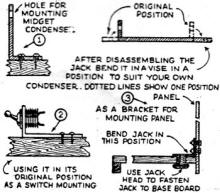

Uses for Old Phone Jacks

Undoubtedly nearly every experimenter who reads this magazine can find

a large number of discarded old-fashioned phone jacks in the junk box. These

should be saved by all means because they can be put to various uses such

as shown in the accompanying drawing. In the drawing we have the base of the

jack forming an "L" bracket which can be used for mounting midget condensers,

volume controls, switches, and a number of other instruments. - James Slocum.

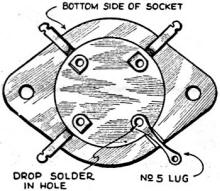

Mending Tube Sockets

How many times have you broken the terminal on your last tube socket? This

happened: to me one time and as I could not obtain another socket immediately,

I had to devise a method of repairing the: damaged one. After much thought,

a No. 5 soldering lug was finally brought to play. This was attached to the

under side of the socket with a drop of solder and presto, the socket was

as good as new! However, you will find that most of the metal parts on sockets

are nickel-plated and it will be necessary for you to scrape the nickel-plated

rivet until all nickel plating is removed and the brass or other metal shows

through, otherwise the solder will not adhere to it. When you are in a "jam"

for a socket some time, try repairing your old ones in this manner and see

how nicely it works out. - Edward Kolakowski,

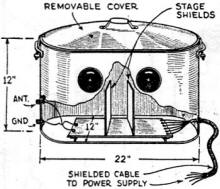

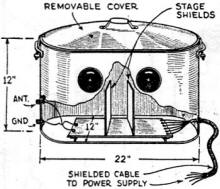

Wash-Boiler Radio Cabinet

After completing a 4-tube short-wave receiving set I found, much to' my

disappointment that it was an excellent receiver of passing automobiles-ignition

noise, of course! The next move was to completely shield the receiver but

funds were low so the idea, presented in the drawing, came into being. The

cabinet I used was made from an old wash boiler which, incidentally, is copper

and provides very effective shielding. The removable cover offers ease in

getting at the inside of the receiver for changing coils or tubes. A shielded

power cable was also used in order to eliminate pick-up. This in connection

with the thorough shielding and the use of a good antenna, practically eliminated

the interference. - C. E. Judson.

|

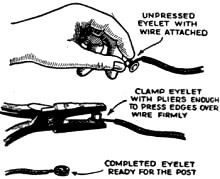

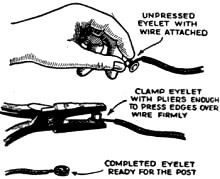

Handy Cable Lugs

Experimenters who have found difficulty in making a neat binding post connection,

when using stranded hook-up wire, will find this odd wrinkle a cheap method

or making positive contact. A number or eyelets (obtainable at any stationery

store) and a pair of pliers comprise the necessary equipment. First, twist

the strands of the end of the wire to be connected and loop this terminal

about one of the eyelets; clamp the eyelet firmly to the pliers, and it will

be found that the end or the wire is being gripped between the two sides of

the eyelet. The latter can then be slipped on and off the binding post rapidly,

and without danger of the wire being forced from under the head of the post,

as often occurs when using stranded hook-up wire. - Walter Kells.

Improving Super Wasp

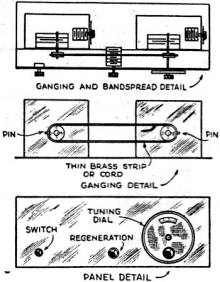

Brass Wheels are put on the two shafts of band-spreading condensers. This

is simple enough but the detector band-spreading condenser's shaft will have

to be removed and a 4-inch shaft inserted so that shaft may reach the new

dial on the new panel. The brass wheels are now tied together by means of

a piece of good fishing twine as shown in the sketch. If one prefers, the

twine may be replaced by a metal strip similar to the one used in the Atwater

Kent receiver. If twine is used a knot is made about the pin in each of the

brass wheels. - Francis E. McGee. W3DM.

Uses for Fahnestock Clips

By cutting off and bending Fahnestock clips, as shown in the drawing, a

very handy plug-in coil receptacle can be constructed. The drawing shows the

method used in mounting these clips. The contacts for the coil are ordinary

machine screws which are allowed to protrude and fit in the slot of the clip.

The clip is to be formed so that when the coil is pushed down into them they

will bear similarly against the nut which holds the screw to the coil form.

Two windings are shown on the coil; however, this could be increased to three

or four windings with a consequent increase in the number of clips. - Wm.

H. Eaton.

|