|

April 1967 Electronics World

Table

of Contents

Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

The April 1967 edition of

Electronics World magazine had a series of articles about designing systems

with electromechanical relays. Even in today's world of solid state relays, there

are still lots of applications for electromechnical relays. Only a handful of American

companies still make them. The application tutorials provided herein are as

valuable to today's engineers and technicians as they were 55 years ago. This

particular piece covers operate and release times of relays. Other articles in

this issue include

Time-Delay

Relays,

Finding Relay Operate and Release Times, and

Arc, Surge, and Noise Suppression.

Operate and Release Times of Relays

Since graduating from the engineering school at the University

of Kentucky in 1937, the author has held supervisory positions in just about every

production and engineering department at Guardian Electric. From 1960 to 1963 he

served as Chief Design Engineer and has been Assistant Chief Engineer since 1963.

He is a Registered Professional Engineer and holds many patents on relay, switch,

and stepper designs. All too often relays are placed in control and logic circuitry

without enough consideration being given as to whether or not the relay operational

time characteristics will assure proper functioning of the circuit under various

operating conditions. A working knowledge of which factors affect relay operating

time can give the circuit engineer or technician confidence in his design.

By Warren Wright / Asst. Chief Engineer, Guardian Electric Mfg. Co.

Definitions of these important characteristics and methods that are used

to modify these parameters.

In general, relays are electromechanically operated switches, thus there are two

items which must be evaluated when considering the time elements of relay function.

These are the electrical characteristics and the mechanical characteristics.

But first, let's define the terms and then consider their relationship to total

relay function.

Definition of Terms

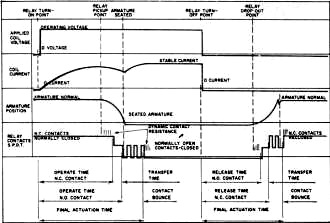

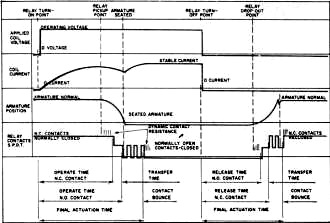

The operate time of a relay is the time interval from the instant of coil-power

application until completion of the last contact function.

The release time is the time interval from the instant of coil-power cut-off

until the completion of the last contact function. (See Fig 1.) Note that the operate

and release times do not include contact-bounce times.

When coil power is applied, coil energizing current increases until the magnetic

flux is sufficient to move the relay armature and its contact-actuating members.

Upon removal of the coil power, magnetic flux does not collapse instantly, but decreases

for some period of time - depending on the circuit, the coil, and the magnetic structure.

When the magnetic flux drops below the "hold-in" value for the particular relay,

the armature and its contact-actuating members return to the normal or de-energized

position.

With these fundamental characteristics in mind, we can now consider the various

relay designs and the effect of circuit characteristics on operate and release times.

D.C. Relays

For d.c. relays, the operate time of a specific relay design may be reduced by

three methods. First, we can overdrive the relay. This is done by increasing the

control voltage, decreasing the coil resistance, increasing the control voltage

and adding a series resistance, discharging a capacitor at an over-voltage charge

into the coil, pre-energizing at some value below pickup voltage (the lowest voltage

at which the relay always operates), using dual-wound coils - one coil for overdrive,

the other to hold the armature in the operated position, using a series resistor

shunted by a capacitor, using a positive temperature coefficient resistor in series

with the coil, and using a series resistor shunted by an N.C. switch - the switch

being operated by the relay being controlled.

Second, we can reduce the pickup voltage of the relay by mechanical means, such

as by reducing return spring pressure, reducing the armature gap, or reducing contact

pressures and gaps.

Third, we can decrease the mechanical inertia by reducing the mass of the moving

elements such as contacts, armature, and contact actuators.

For d.c. relays, the inherent release time of a specific design may be increased

by using a parallel capacitor and series resistor, a parallel shunt resistor or

switch, parallel diode, or by reducing the residual magnetic air gap.

Relay manufacturers produce many varieties of relays with operate and release

times ranging from minimal values of less than one millisecond to some of the more

exotic solid-state relays with maximum times of 30 minutes or more.

Fig. 1 - Typical d.c. operation of a relay with a resistive

d.c. load.

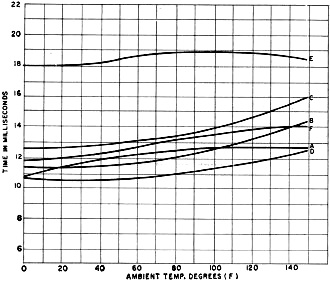

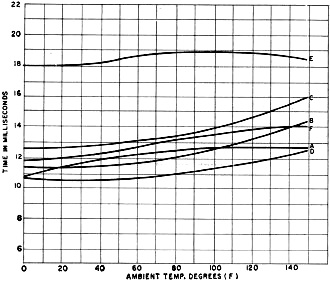

Fig. 2 - Variations in operate or attract times at various

ambient temperatures for six general-purpose d.c. relays.

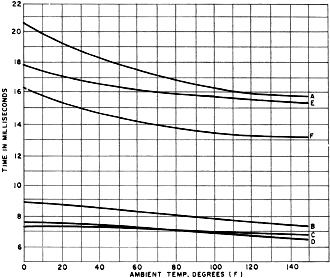

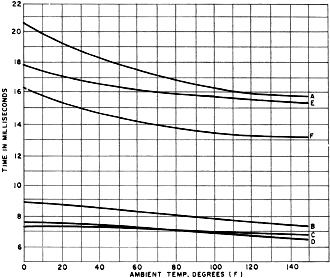

Fig. 3 - Variations in the release times at various ambient

temperatures for the same six general-purpose d.c. relays.

When specific time characteristics are needed, the relay manufacturer can usually

provide relays to match the circuit requirements either from "standard" relays or

as "specials" designed for a specific function.

The National Association of Relay Manufacturers (NARM) has not set standards

with respect to fast or slow response. In general, relays which have operate and

release times under 3 milliseconds are considered fast-operate and/or fast-release.

Relays with function times of 50 milliseconds or more are usually considered slow-operate

or slow-release. Relays with function times between 3 and 50 milliseconds are medium-operate

and release and this is the range into which most general-purpose relays fall. Relays

which are purposely designed for slow function time are classified as time-delay

relays. These are covered in another article in this special section.

Relay manufacturers produce a bewildering range of relays for use in over a hundred

"usage" classifications, with thousands of varieties and modifications in each classification.

It is obviously impractical to analyze all of these types, therefore we will only

cover some of the most popular general-purpose relays.

The graphs of Figs. 2 and 3 show the effects of ambient temperature changes on

the attract and release times of some typical general-purpose, d.c.-powered relays.

From this we can see that the attract or operate time increases with temperature

and the release time decreases with temperature rise (although circuit components

may modify this).

When we consider that relays heat up either under extended energization or repeated

cycling, we can expect a relative shift in operating time characteristics, depending

upon the frequency of operation.

Relays from different manufacturers, but of the same type, generally have similar

operating-time characteristics. It will be noted that some relay types change more

with temperature than others - this is inherent in the design of the relay but.

in general, the time change is within ±10% over an ambient temperature range of

0°F to 160°F.

Other factors affect timing, such as changes in operating voltage or current.

in which the attract time varies inversely with coil power and the release time

varies directly with coil power. Where operation time is critical, the relay should

be evaluated in the circuit under the most adverse combination of variables.

Power-supply inductance will increase the operate time of d.c, relays depending

upon the L/C ratio of the circuit. Resistance in the power-supply line will tend

to decrease the operate time. Relays which are wired in parallel would aggravate

these effects. Arc suppressors or coil shunts will increase the release time of

relays.

Basically, d.c. relays are reasonably consistent in their timing characteristics

under the same operating conditions, but this is not the case with a.c. relays.

A.C. Relays

Other variations in both attract and release times are due to the added factor

of the instantaneous (turn-on or turn-off) voltage change. The source voltage varies

from zero to peak 120 times per second, thus any voltage from zero to peak may be

applied across the coil at the instant of either "turn-on" or "turn-off".

Examination of a typical 60-Hz sine wave will show that most of the time the

instantaneous voltage at "turn-on" or "turn-off" will be higher than the pickup

voltage of the relay, so that the time characteristics are usually within a reasonable

range. Frequently, however, the probability of turning on or off at lesser voltages

catches up with us and the operating time suddenly changes. This voltage variation

is further complicated by the magnetic flux distribution between two or more functional

pole faces. Remember that a.c. relays generally have one core face shaded by a copper

ring to cause a phase displacement in the magnetic flux. This phase shift is necessary

to provide relay hold-in during current reversal. Thus, we have an operational time

range rather than a specific operation time. The manufacturer generally specifies

the average function time for a.c. relays.

Modification of operational time for a.c. relays may be accomplished in a manner

similar to that for d.c. relays, but the actual time of operation will vary because

of the sine-wave voltage applied. We must conclude, therefore, that straight a.c.

relays should not be used in circuits where precise repeatable narrow-range operational

times are required.

The mechanical characteristics which affect operational time apply to both d.c.

and a.c. relays and what affects one type will usually affect the other type in

the same manner.

Increases in mass, whether it be in contact actuators, the contacts, or armature

will slow the operational time. Release time will be increased by minor contact

welding or sticking, mechanical wear, and residual magnetism.

We have not attempted to give charts showing precise operating characteristics

of relays because the timing is subject to so many variables from relay to relay

type, depending upon adjustment, type and number of contacts, voltage variation,

source impedance, line resistance, wear factors, etc. Information on timing characteristics

is available from the manufacturer and should be used whenever operate and release

timing is critical.

Posted March 15, 2022

(updated from original post on 7/3/2012)

|