|

May 1955 Popular Electronics

Table of Contents Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

By the time most of us

who even remember cathode ray tubes (CRTs) were first introduced to them, the

technology and manufacturing processes had been pretty much perfected -

especially for the standard 525-line (or 625-line outside the U.S.) resolution

type. The National Television System Committee (NTSC) published a

standard for black and white (B&W) television in 1941 and then for color in

1953. This "Picture Tubes" article in a 1955 issue of Popular Electronics

provides a look inside a CRT manufacturing plant at General Electric.

If you want one of the best explanations I have ever seen on how a TV picture

scan is implemented, check out this video by

Displaced

Gamers. If you don't understand raster scanning after watching it, you never

will. You might be surprised to learn that there were not actually 525

lines of picture information, but that only about 480 to 487 lines of picture

were included - the rest were for scan synchronization, retrace and blanking,

and special signal information. In fact, the modern 480i digital standard

evolved from that 480 lines of picture info. You'll also learn a little about

how video game consoles repurposed the NTSC scan format to facilitate faster

video updates.

See also How the Cathode-Ray Tube Works,

Picture Tubes,

TV

X-Rays,

TV

X-Rays Are Back.

Picture Tubes

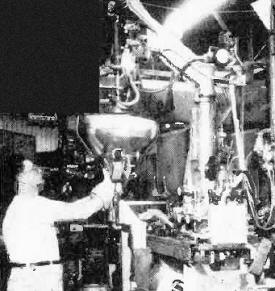

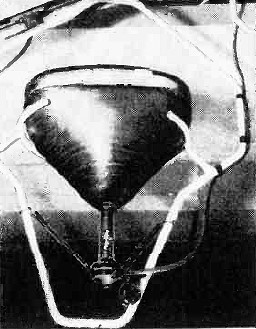

The first step in actual processing of a picture tube is screening,

in which the phosphor picture screen is applied to the inside of the bulb's face.

Note screens inside tubes at left. Hoses pour one mixture into bulb, other comes

later.

On the screening conveyor, picture tubes move slowly along as

the phosphor-silicate mixture settles inside of their face areas. At far end of

belt, tubes will be tipped, and water will be run off.

Careful inspections follow the picture takes all the way during

processing. Here as operator inspects phosphor screens on tubes after they have

been removed from the screening conveyor belt.

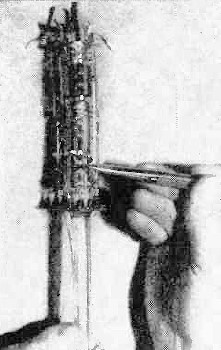

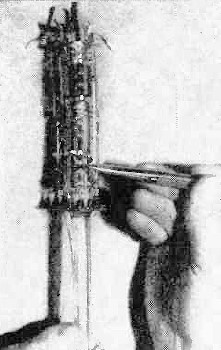

Electron gun, which later will be sealed into neck of a picture

tube, receives final inspection after assembly. At bottom are leads and glass tubulation

of stem assembly. Above, in order, are grid No. 1, grid No. 2, and metal sections

of anode structure. At top is focus electrode, the "getter," etc.

Processing "en route" takes place as completed tube is "aged"

on a conveyor taking it to final test section. "Aging" is process whereby electrical

characteristics are stabilized in tube.

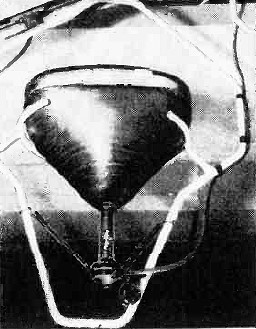

"Merry-go-round" rotary aluminizer automatically coats interior

of tube bulbs with film of aluminum four one-millionths of inch thick. In finished

tube, this metallic layer on the back of the phosphor screen will reflect increased

illumination for brighter pictures and better contrast. Machine handles 24 tubes.

The "heart" of your television set is the incredibly complex C-R tube. Here is

how it is made.

Do you take your television receiver so much for granted that you never wonder

about the complex circuitry and the vast amount of engineering "know-how" that is

represented in your living room?

One of the most fascinating components in your television receiver is the picture

tube itself. While this is almost the only "internal" component that everyone gets

to see, very few televiewers know how it is constructed or what is involved in the

manufacture of such a tube.

The photographs on this and the two succeeding pages show how such tubes are

"built" at the General Electric Company plant in Buffalo. This factory now turns

out thousands of picture tubes each day - including the 21-inch size.

The mass production of picture tubes is no simple proposition, but the operation

isn't as much a difficult effort as it is a delicate one. Every step of the operation

must be carefully controlled.

Every part that goes into a tube must be checked and inspected all the way through

production. The finished tube must meet exacting standards before it is shipped

to a set manufacturer or released for replacement applications.

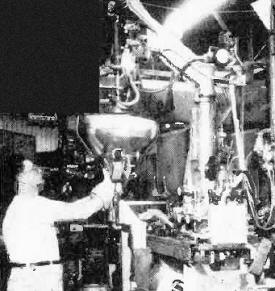

After all of its processing, the picture tube bulb is now ready

for installation of its electron gun. Step is performed on this rotary gun-sealing

machine by welding process.

Almost completed, the picture tube is swung from automatic "tip

off" machine after being pumped out to a vacuum and sealed at end of its neck. Later

the base is added and the tube completed.

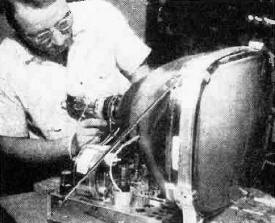

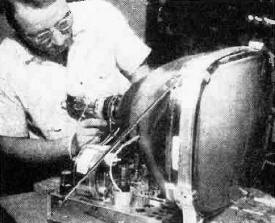

Final inspection of the picture tube consists of checking it

for electrical stability, short circuits, brightness, and gas. Operator adjusts

standard test pattern on a 21-inch picture tube.

In place in a home receiver chassis, the picture tube is checked

before the completed unit is installed in a cabinet. Unit around neck of tube deflects

electron beam to sweep the screen.

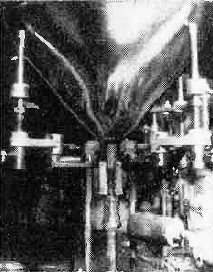

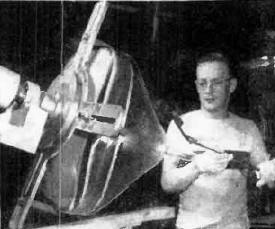

A "double-jointed" paintbrush, which bends after insertion through

the bulb's slender neck, coats entire cone of nonaluminized bulb with an electrically-conductive

paint as the bulb is rotated.

Into the bakeout oven's 350 degree C heat go the picture tube

bulbs after screening and aluminizing or inside painting. Here heat removes the

moisture and gas from these prepared tube bulbs.

Basically, a picture tube is a conical glass bulb with a phosphor screen on the

inside of the bulb face. Mounted in the neck of the bulb is an electron "gun" whose

electron beam is directed at the screen to activate it and reproduce the transmitted

image.

The metal electron gun parts, including units about the size of a thimble, magnets

not much larger than a pencil eraser, and tungsten wire finer than a human hair,

are weighed, measured with fine-precision gauges, or inspected on a shadowgraph

which projects their silhouettes, magnified 20 times, on a translucent screen.

These various components eventually emerge as a television picture tube after

going through the processes which are pictured in the photographs accompanying this

article.

During 1955, General Electric statisticians estimate that over 11,750,000 picture

tubes will be manufactured, 5,600,000 of which will be earmarked for replacements

in existing television receivers. The percentage of color TV picture tubes will

still be relatively small, with the prediction, as of now, at about a quarter of

a million tubes for the multi-hued television sets.

The next time you step up to your TV set to turn on your favorite program, take

a long, hard look at the "Cyclops" staring out at you. It is an eye-opener if you

will only take the time to examine this electronic eye to your world of entertainment,

education, and sheer fun. It can truly be classed as an "electronic miracle" of

the first order.

Posted August 21, 2019

|