|

August 1949 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

A well-planned and

installed waveguide system is always impressive. With enough switches, couplers,

transitions, adapters, and various and sundry other accoutrements, the result

can be downright artistic in appearance. Although usually the most costly form

of electromagnetic wave transmission, it has the decided advantage of having by

far the lowest path loss and highest isolation of any of the other forms of

transmission - over the air, coaxial cable, twin lead, etc. This, Part IV of an

VIII-part series on microwaves by author C.W. Palmer, appeared in the August

1949 issue of Radio-Electronics magazine. He discusses E- and H-planes,

inductive and capacitive "windows," tuning screws, proper joining of waveguide

sections, and more.

Microwave Series -- Part 1: How Radio Waves

Can Be Transmitted Inside Pieces of Pipe (4/49), Part II: An Introduction to Standing

Waves, Cavity Resonators, and Representative Examples of u.h.f. Plumbing (5/49),

Part III: Tubes for the Microwave Frequencies, Giving Special Notice to the Lighthouse

Triode, Velocity-Modulated Tubes, and the Magnetron (6/49),

Part IV: How

Waveguides Are Joined and Tuned for Lowest Possible Loss (8/49),

Part V: Special

Sections of Waveguide Are Employed as Transformers (9/49),

Part VI: Some Equipment

Used for Measuring Frequency, and Crystals for Receiver Frequency Conversion (10/49),

Part VII: Action of Below-Cutoff Attenuators and of TR and Anti-TR Switches

(11/49),

Part

VIII: Receiving and transmitting antennas for microwave communication.

How Waveguides Are Joined and Tuned for Lowest Possible Loss

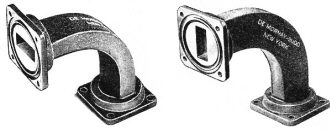

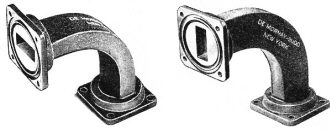

Fig. 1 - In bending waveguides, use is made of either the E or

the H bend. Both appear here.

Part IV - How waveguides are joined and tuned for lowest possible loss

By C. W. Palmer

DeMornay Budd Photo

So far we have learned how waveguides are used to transfer microwave radio power

from an oscillator or transmitter to an antenna, and from the antenna to the receiver's

amplifying and detecting circuits.

We have learned that the familiar radio quantities - inductance, capacitance,

impedance, reactance, and resistance-are found in r.f. plumbing, but that their

appearance is entirely new. And since we are dealing with wave propagation instead

of conduction of r.f. currents as in low-frequency radio, we must learn a new set

of rules.

In this part of the microwave series we will attempt to express those rules in

a form that will help the radio man to understand better the do's and don'ts of

r.f. plumbing.

One of the most important things to learn in using waveguides is to avoid discontinuities

or changes in the internal mechanical shape of the guide from one section or piece

of apparatus to an-other when joining them together in a "circuit."

Look at Fig. 1 as an example. It shows two types of L bends used extensively

in r.f. plumbing. The first is known as an E bend, and the second is called an H

bend. It is easy to remember which is the E and which the H bend if you think of

the E as the "easy" and the H as the "hard" bend (if it were possible just to bend

a piece of straight guide to make a right-angle turn, which it isn't).

In manufacturing these bends, deviation from the inside dimensions of the straight

section by even a few thousandths of an inch in the bent portion will increase the

loss from a nominal 0.02 decibel for such a section to several decibels, with a

corresponding increase in the standing-wave ratio.

Fortunately such discontinuities can be taken care of by introducing into the

guide obstacles that produce reflections which cancel the unwanted ones.

The matching devices most commonly used are diaphragms and tuning screws. The

diaphragm, or window as it is sometimes called, is an aperture of thin metal placed

across the waveguide. Such a window introduces either inductive or capacitive reactance

depending on the direction of the slit.

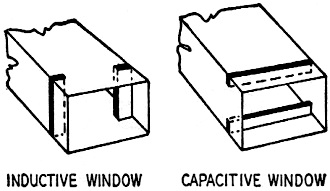

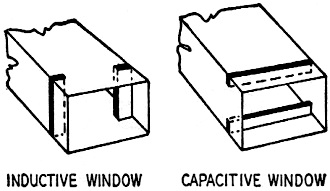

Fig. 2 - The inductive and capacitive windows.

Fig. 2 shows inductive and capacitive windows. For an inductive window the edges

of the slit are parallel to, and for the capacitive window perpendicular to, the

electric field. Usually these windows are soldered in place and are not variable.

Where large amounts of power are to be carried in the waveguides, inductive windows

are preferred because the capacitance type breaks down, causing arcing and loss

of power.

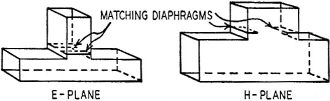

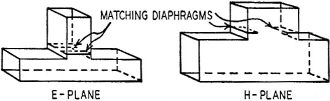

Several examples of the use of fixed windows in waveguide circuits are shown

in Fig. 3, which shows E and H tees used for branching or splitting the waves into

two paths. The windows in these tees balance out reflections that would otherwise

be introduced by the branch line and would introduce losses in the main waveguide

path.

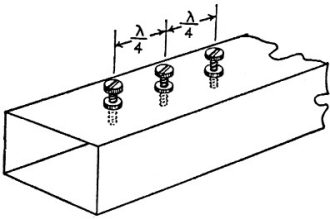

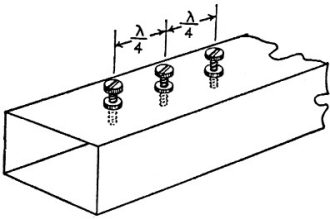

Sometimes it is desirable to have a variable reactance in a waveguide set-up

to permit balancing out undesired reflections. In such cases tuning screws - small

cylindrical posts projecting into the broad face of the guide as shown in Fig. 4

- are used. These screws provide capacitive reactance which varies with the penetration

of the post into the guide. A single screw may be sufficient, but usually three

screws are provided at quarter-wave-length intervals along the guide.

Sometimes it is desired to insert in a waveguide a device that will either pass

a desired mode (modes of propagation were discussed in Part I) and no other, or

reflect completely the power in a certain mode. Resonant diaphragms or windows are

used for this purpose. A thin rectangular ring of the proper dimensions placed across

the inside of the rectangular waveguide and separated from it by insulation will

reflect, for example, all the T E0,1 mode transmitted through the guide.

If a thin metal diaphragm across the guide is provided with an opening of the

proper size, all the power in the T E0,1 mode will be transmitted.

Resonant slits in the waveguide diaphragms are also useful for passing waves

of low power and rejecting those of higher power. The slit is so narrow that breakdowns

occur, and the resonant condition is temporarily removed. A device of this sort

is useful for preventing the direct power of a transmitter from reaching and damaging

a receiver connected to the same antenna system, during transmit periods, while

allowing incoming radio waves to be received normally. In a radar system a special

form of such a device is called a TR or ATR box, and will be discussed in detail

later.

A microwave primer

It is frequently necessary to use long stretches of waveguides, and it is very

unusual for them to proceed in a straight line. Bent and twisted sections with the

bends in both E and H planes, tees for branch lines, etc., must be used to fit the

needs of the individual installation.

In using these lengths with tee's, L's, etc., certain rules must be observed

to obtain the desired results. These are summarized here in the following eight

items.

1. A shorted end of waveguide (as the side arm of a tee or a stub) an odd number

of quarter wavelengths long reflects an "opening" where it joins another waveguide.

Waves in the main arm would travel into such a side arm as well as traveling through

the main arm.

2. A shorted end of waveguide any number of half wavelengths long reflects a

"solid wall" where it joins another waveguide. Waves in the main arm of a tee would

travel through without entering such a side arm for this reason.

Fig. 3 - Windows used in waveguide branch.

Fig. 4 - Tuning screws for varying reactance.

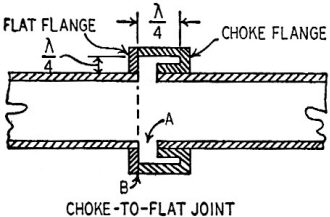

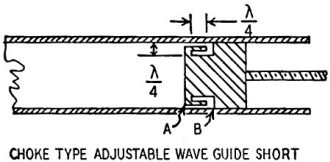

Fig. 5 - The choke flange, perfect connector.

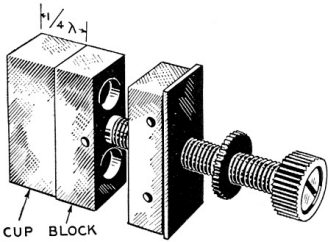

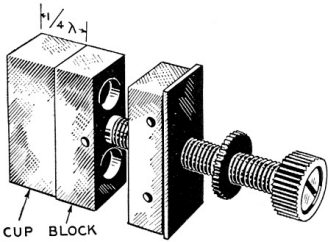

Fig. 6 - The cup-type plunger reduces losses.

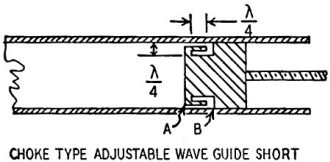

Fig. 7 - Improved plunger uses choke circuit.

3. A quarter-wave section of wave-guide has opposite impedances at its ends (if

impedance is high at one end, it is low at the other) just as in ordinary types

of co-axial and parallel transmission line. (This summarizes rules 1 and 2.)

4. The Q of a waveguide is a function of frequency and also depends on the ratio

of volume to inside area of the guide. Q's of 25,000 are not uncommon in waveguides

and resonant cavities.

5. The characteristic impedance differs with different modes of operation. In

a rectangular waveguide the impedance is proportional to the narrow or b dimension

of the guide. It varies from about 475 ohms to zero as the b dimension is reduced.

6. The wavelength in a hollow wave-guide (as measured in a slotted waveguide

section) is always greater than the wavelength of the same wave in air, due to the

multiple reflections from the walls of the guide.

7. Sections of open and closed waveguides may be used as switching circuits by

applying the principles of Rules 1 and 2 above.

8. Standing waves in waveguides are checked in a manner similar to that used

for co-axial lines. A section of waveguide with a narrow slot parallel to the axis

of the guide is used. A probe with a crystal detector or a small fuse (1/200 ampere)

heated to almost the blowing point by direct current is used to detect the presence

of standing waves as with a slotted co-axial line at lower frequencies.

Joints in waveguides

Sections of waveguide may be soldered together end to end. If the sections line

up and touch, losses and reflections introduced by the joints are negligible.

However, for maintenance purposes and to make waveguide apparatus useable in

more than one installation, it has become common usage to terminate waveguides with

flanges on the ends which are soldered to the guide and machined flat on the ends.

These flanges are bolted together. Experience has shown that this type of joint

can be made better than even the average soldered guide-to-guide joint if care is

taken to make uniform contact.

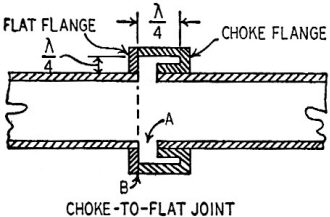

To reduce further the possibility of losses due to waveguide joints, it is considered

good practice to use the "choke flange" joint, butting a choke flange always against

a flat one.

The principle on which this choke flange works can be readily understood from

waveguide Rule No.2 above. See Fig. 5. This shows a cross-section view of a choke-to-flat

joint. The slot left by the junction of the two waveguide sections is a half wavelength

long at the optimum frequency of operation of the waveguide, which means that the

side cavity A reflects a "solid wall" to the main guide so that there can be neither

leakage of r.f. nor dicontinuity to cause reflections in the main guide path.

In addition to the above, the point B where contact is actually made between

the two waveguide sections is at a point of zero current, and perfect electrical

contact need not be made between the two sections as is necessary in joining two

flat flanges.

Such choke couplings are frequently used as "wobbly" or nonrigid connections

between waveguide sections. They are used, for example, at the junction of an antenna

where it is desired to shift or rotate the final section of guide to orient the

antenna for peak response.

As a rigid connection the loss in a choke-flange joint is in the order of 0.02

db, compared to about 0.05 db for a well-made contact joint. The nonrigid connection

mentioned, with a gap of about 1/16 wavelength between the choke and flat flange,

has a leakage of about 0.3 db.

Plungers for shorting bars

In terminating side arms as described in the rules above, it is sometimes desirable

to make movable shorting plates or plungers so that the lines can be tuned exactly

to a desired quarter- or half-wavelength point.

Plungers can be either solid blocks, cup terminations, or choke terminations.

The solid blocks must make good electrical contact at all points around the edge

with the inside of the guide, or behavior will be erratic as the plunger is moved

and power may leak past the termination.

Better results are obtained with a cup contact as shown in Fig. 6. Contact is

made with the inside walls of the guide a quarter wavelength from the plunger, where

the flow of current in the walls of the guide is zero. Losses in this type of termination

can be held to as little 0.08 db.

An improved termination is the choke plunger which uses the same principle as

the choke coupling. As shown in Fig. 7, no mechanical contact with the inside walls

of the waveguide is made at the front surface of the plunger. Contact is made at

B where the current is zero. Choke plungers have losses in the neighborhood of 0.02

db.

Dielectric in waveguides

The fact that the introduction of a dielectric inside waveguide will decrease

the "cutoff" wavelength has been used practically in a so-called "line stretcher."

This device introduces controlled amounts of dielectric into the guide to tune it.

The effect of an ideal dielectric in a waveguide is to increase its apparent

size. It also lowers the impedance in all but one TM (transverse magnetic) mode.

The losses of a guide filled with solid or liquid dielectric are higher than for

an air-filled or gas-filled guide. However, the effect is slight.

An exception to the above and a point of caution to the experimenter in microwaves

is the effect of water. Small amounts of water condensed on the inside of a waveguide

may introduce losses up to 1/2 decibel per foot of waveguide. This is caused, not

only by the large dielectric loss characteristic of water at high frequencies, but

also by the high dielectric constant of water. This is why some waveguide installations

are pressurized or, charged with an inert gas.

Posted October 4, 2021

|