|

Here is a million dollar idea for you to

consider. I hereby dub it the "Drone-Based Field Measurement System™"(dB-FMS™). Here is a million dollar idea for you to

consider. I hereby dub it the "Drone-Based Field Measurement System™"(dB-FMS™).

The concept came to me while reading a column in QST magazine discussing the

use of the

EZNEC antenna radiation pattern prediction software. As you know

unless an antenna is situated in a perfect, unobstructed environment like in the

middle of a desert with a perfectly uniform ground or on a space-based platform,

physical obstacles and variations in surface conductivity can significantly alter

the 3-dimensional field distribution. Columnist

Joel Hallas (W1ZR) is a master at EZNEC and is routinely called

upon to model antenna systems for people. As important as length and orientation

of antenna elements are, the ground plane configuration can have a profound impact

on the radiation pattern, particularly when the antenna is less than a wavelength

above ground. Areas of low soil conductivity require placement of conductive wire

radials below, on top of, or above the ground surface, at specific lengths (or not),

arrayed in various spacing (in degrees) between lines, sometimes with bends and

sometimes with fold-backs. In extreme cases 'salting' the ground is necessary to

promote sufficient conductivity. The list of intentional antenna system variables

is endless. Add to that vehicles, building structures, overhead and buried power

lines, chain link fences, and a host of other unintentional conductive objects that

often are a significant fraction or fractions of the operational wavelength, and

you are left with a nearly incomputable field pattern for in-situ environments.

That

is not to say modeling the system with known, significant variables is not worth

the trouble - it definitely is - but it would be nice to have a convenient, affordable

means to determine the 'real' field distribution pattern. 'Affordable' is a relative

term, of course, but I refer to something that could be packaged and sold as a turnkey

outfit for somewhere in the $5,000-$20,000 range (prices could easily be reduced

over time). An open air test site (OATS) is the standard choice for making such

measurements, but it has its own limitations. Available qualified real estate in

regions where most facilities need to be located are not only scarce but extremely

expensive. Training and utilizing personnel to obtain useful measurements can also

be very expensive unless antenna measurement is a main aspect of the business' service

and/or product offerings. Even the best OATS setup or electromagnetic anechoic chamber

can only provide meaningful results based on specific ambient conditions. A fully

parameterized antenna with an ideal pattern, fed with metrology quality cable or

waveguide, and connected to a laboratory grade transmitter and/or receiver, will

almost certainly not perform the same way in its installed environment. What's an

engineer or technician to do? That

is not to say modeling the system with known, significant variables is not worth

the trouble - it definitely is - but it would be nice to have a convenient, affordable

means to determine the 'real' field distribution pattern. 'Affordable' is a relative

term, of course, but I refer to something that could be packaged and sold as a turnkey

outfit for somewhere in the $5,000-$20,000 range (prices could easily be reduced

over time). An open air test site (OATS) is the standard choice for making such

measurements, but it has its own limitations. Available qualified real estate in

regions where most facilities need to be located are not only scarce but extremely

expensive. Training and utilizing personnel to obtain useful measurements can also

be very expensive unless antenna measurement is a main aspect of the business' service

and/or product offerings. Even the best OATS setup or electromagnetic anechoic chamber

can only provide meaningful results based on specific ambient conditions. A fully

parameterized antenna with an ideal pattern, fed with metrology quality cable or

waveguide, and connected to a laboratory grade transmitter and/or receiver, will

almost certainly not perform the same way in its installed environment. What's an

engineer or technician to do?

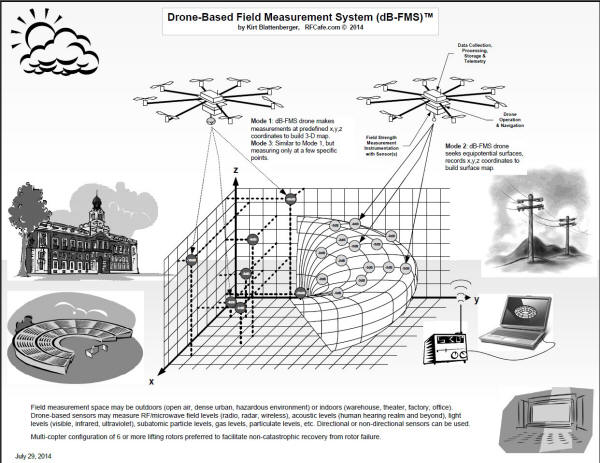

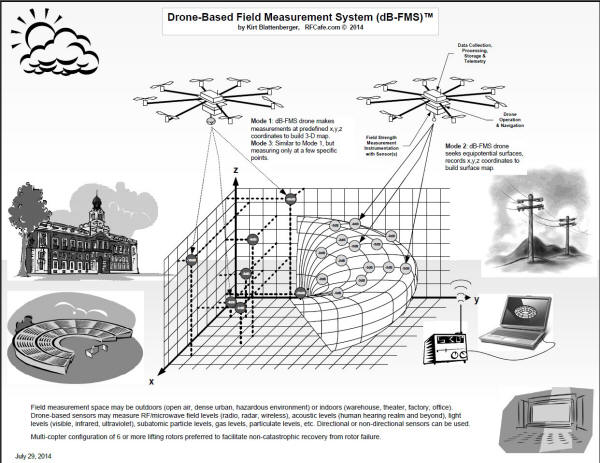

I have a brilliant solution (IMHO). Use one of the commercially available high-end,

powerful, GPS-guided, precision radio controlled drones as a platform for a field

intensity measurement instrument. Software is already available for programming

the drone to fly to and hover at a defined array of points in space, so all that

needs to be done is configure the field measuring instrument to record values at

each point and then generate a 3-dimensional radiation pattern from the data. Depending

on distance to which the drone must fly to measure the pattern, data can be streamed

real-time via wireless link, or it can be stored onboard for downloading. Custom

guidance software could fully automate the entire measurement process by building

a user interface allowing the input of a 3-dimensional spatial map of the region

needing to be measured, including terrain, buildings, towers, human activity, no-fly

zones, power lines, etc. After defining of the boundaries for measurement, points

within those boundaries would limit the drone's flight to within a region of safety

while situating the drone at user determined measurement points. Alternately, a

sophisticated algorithm could determine measurement points based on the desired

degree of resolution and accuracy needed while taking into account obstacle avoidance.

Yet another measurement mode would be to use a predictive and adaptive algorithm

to seek out equipotential points in space to enable accurate graphs of familiar

field patterns to be constructed.

Really large field measurement areas might require the use of more than one airborne

platform in order to expedite the process. Software or manual input could allocate

measurement space to each drone as required. Wireless links for control on a commercially

available drone operates via a spread spectrum modulation system in the 2.4 GHz

unlicensed (ISM) frequency band, so frequency contention is not an obstacle to coordinated,

simultaneous flight.

Such a system,

once you figure out how to work around or in congruence with the highly restrictive

regulations of the Federal Aviation Administration (or you own country's governing

agency), you can quickly and inexpensively obtain useful coverage information even

in populated areas. Operation in all environments will be subject to rules prohibiting

flight above certain altitudes and within certain distances of airports, government

property, etc., so due diligence will need to be practiced by the user lest he/she

end up being visited by a joyless team of federal law enforcement officers in full

SWAT gear. Drone shooting is also becoming a popular sport over rural property,

so take caution there as well. Such a system,

once you figure out how to work around or in congruence with the highly restrictive

regulations of the Federal Aviation Administration (or you own country's governing

agency), you can quickly and inexpensively obtain useful coverage information even

in populated areas. Operation in all environments will be subject to rules prohibiting

flight above certain altitudes and within certain distances of airports, government

property, etc., so due diligence will need to be practiced by the user lest he/she

end up being visited by a joyless team of federal law enforcement officers in full

SWAT gear. Drone shooting is also becoming a popular sport over rural property,

so take caution there as well.

There are applications other than electromagnetic field pattern measurements

that can be accommodated with my dB Field Measurement System. There is no reason

that an acoustic measuring instrument could not be flown to various points to determine

sound levels within auditoriums and outdoor theaters during setup. A directional

sensor could be rotated by the drone at each position to determine direct path and

reflection (multipath) effects. Electromagnetic field measurement could use the

same scheme for determining multipath signal strength relative to the direct path.

A photometer could be hoisted aloft to measure light distribution in practically

any environment. Gas sensors, particulate matter sensors, subatomic particle sensors,

wind sheer sensors, temperature sensors, and nearly any other type sensor can quickly

and easily go to places unreachable by humans and their test gear. Since almost

all commercially available drones are electric powered, they are quiet so as not

to draw attention to themselves, and they do not significantly contaminate the measurement

environment (other than from air vortices).

The drone configuration I have in mind is one of the multi-rotor models rather

than an airplane or a helicopter. The 'dB-FMS' scheme relies on a stable platform

that can autonomously fly to and maintain a precise position in space, possibly

for an extended period, and have the ability to rotate about the vertical axis for

directional sensing. Fixed wing aircraft (airplanes) cannot do that. Helicopters,

having only a single lifting rotor, can potentially suffer from a single point failure.

Professional quality multi-rotor systems typically incorporate at least six (usually

eight) lifting rotors and are able to compensate for one or more rotor failures

to at least be able to land safely with the onboard equipment.

The applications for a Drone-Based Field Measurement System are so numerous that

an entire industry could be built around the concept. In fact, it would behoove

major commercial instrumentation companies like Rhode & Schwarz, Keysight Technologies

(recently Agilent and not so recently HP), National Instruments, and Rigol to seriously

consider embarking on such a product line. Even defense companies like Lockheed

Martin, Northrop Grumman, Cobham, Boeing, Thales, and others would benefit greatly

from developing special purpose Drone-Based Field Measurement Systems. Depending

on the measurement capability and price point, customers would range from hobbyists

wanting to fine tune Ham radio antenna configurations for effective coverage (at

home or in the field), to small, independent entrepreneurs that want to provide

field measurements services to customers, all the way up to complete fixed base

and mobile facilities that provide contract measurement capability needing in-situ

coverage determination.

First Person View (FPV) systems, the subject of much debate and

heavy government regulation, will extend the operational range of a dB-FMS by providing

the operator the advantage of real-time visual assessment of the measurement scenario

from the perspective of the measurement platform (drone) itself. Depending on the

fields being measured and where the drone lofting platform must travel to make the

measurement, an out-of-sight situation may be required either because the drone

must position itself behind an object where the operator cannot directly have visual

contact with or, or the drone may need to fly to such an extreme location that its

apparent size is too small to discern. Regardless of distance, an onboard camera

with wireless image streaming would add a measure of safety to the mission. Such

a feature would permit a relatively low number of personnel to be present during

missions because remote spotters would not be needed (although it might be a good

idea anyway). The FAA, Department of Homeland Security (DHS), and other regulatory

and law enforcement agencies are creating legislation and regulations now to seriously

limit any type of FPV systems (other than the ones they use) because of perceived

terrorist threats and public safety concerns. Accordingly, any effort to implement

a Drone-Based FMS should include a thorough familiarization with the limitations

imposed by such agencies. Since these activities would be considered to be other

than for hobby (model aircraft), they would be governed by rules outside the special

accommodations provided for members of the

Academy of

Model Aeronautics (AMA - very active in protecting those

privileges). AMA requires FPV flight to have a spotter to work in conjunction

with the pilot to maintain a visual link to the model. First Person View (FPV) systems, the subject of much debate and

heavy government regulation, will extend the operational range of a dB-FMS by providing

the operator the advantage of real-time visual assessment of the measurement scenario

from the perspective of the measurement platform (drone) itself. Depending on the

fields being measured and where the drone lofting platform must travel to make the

measurement, an out-of-sight situation may be required either because the drone

must position itself behind an object where the operator cannot directly have visual

contact with or, or the drone may need to fly to such an extreme location that its

apparent size is too small to discern. Regardless of distance, an onboard camera

with wireless image streaming would add a measure of safety to the mission. Such

a feature would permit a relatively low number of personnel to be present during

missions because remote spotters would not be needed (although it might be a good

idea anyway). The FAA, Department of Homeland Security (DHS), and other regulatory

and law enforcement agencies are creating legislation and regulations now to seriously

limit any type of FPV systems (other than the ones they use) because of perceived

terrorist threats and public safety concerns. Accordingly, any effort to implement

a Drone-Based FMS should include a thorough familiarization with the limitations

imposed by such agencies. Since these activities would be considered to be other

than for hobby (model aircraft), they would be governed by rules outside the special

accommodations provided for members of the

Academy of

Model Aeronautics (AMA - very active in protecting those

privileges). AMA requires FPV flight to have a spotter to work in conjunction

with the pilot to maintain a visual link to the model.

Let me reiterate

that if you plan to conduct any form of drone flight, you must fully inform

yourself of aviation and communications regulations in the airspace you plan to

occupy. Severe penalties including monetary fines, equipment confiscation, and incarceration

may result if you violate the laws. When researching drones, know that they are

also referred to as Unmanned Aircraft Systems (UAS), Unmanned Aerial Vehicles

(UAV), and small Unmanned Aircraft Systems (sUAS), hexacopters, and octocopters. Let me reiterate

that if you plan to conduct any form of drone flight, you must fully inform

yourself of aviation and communications regulations in the airspace you plan to

occupy. Severe penalties including monetary fines, equipment confiscation, and incarceration

may result if you violate the laws. When researching drones, know that they are

also referred to as Unmanned Aircraft Systems (UAS), Unmanned Aerial Vehicles

(UAV), and small Unmanned Aircraft Systems (sUAS), hexacopters, and octocopters.

If you take my idea and develop and market a Drone-Based Field Measurement System,

please be sure to invite me to sit on your board of directors and cut me in on a

healthy chunk of stock during the IPO. At the very least, provide some attribution

to me for having planted the seed. The law firm of

Dewey, Cheatum, & Howe will be monitoring the situation for

me. Remember, you read about here first.

Drone-Based Field Measurement

System (dB-FMS) Diagram™

Click here for scalable

PDF version

of the dB-FMS™.

Author: Kirt Blattenberger

Note: This web page was originally published in 2014 at "https://www.rfcafe.com/miscellany/homepage-archive/2014/Drone-Based-Field-Measurement-System.htm"

, but was relocated to "https://www.rfcafe.com/miscellany/smorgasbord/Drone-Based-Field-Measurement-System.htm"

on February 11, 2019 for logistical reasons.

Archive.org has a record of the page at

https://web.archive.org/web/20150320081521/https://www.rfcafe.com/miscellany/homepage-archive/2014/Drone-Based-Field-Measurement-System.htm

Posted August 11, 2021

(updated from original post on 7/29/2014)

|