|

April 1967 Electronics World

Table

of Contents

Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Electronics World, published May 1959

- December 1971. All copyrights hereby acknowledged.

|

Relays are another topic that never goes out of date. Even with

the advent of fully solid state relays that use semiconductors

in the conduction path, there are still many applications that

only mechanical contacts can satisfy. Very high power, whether

it be high voltage, high current, or both, cannot yet be handled

by semiconductors - at least not economically. Yes, there are

switching diode arrays that can handle very high powers, but

they are typically very expensive. This article is one of a

group of articles about relays in the April 1967 Electronics

World. All will eventually be re-posted here on RF Cafe.

Here are links to the other relay articles:

Operate and Release Times of Relays,

Reed Relays,

Time-Delay Relays,

Finding Relay Operate and Release Times,

Arc, Surge, and Noise Suppression

Time-Delay Relays

By Jerry E. Elpers

Solid-State Products, Potter & Brumfield (Div. American

Machine & Foundry)

The author is presently employed as Solid State Products

Sales Manager. Prior to this, he did circuit design in the Solid

Stale Switching Group. He holds a BSEE from Evansville College,

Evansville, Ind. and has done graduate work at Purdue. He is

a member of IEEE and Sigma Pi Sigma.

Factors to consider in selecting a relay that produces a

predetermined delay. Included is data on thermal, motor-driven,

pneumatic, RC, slugged, hydraulic, escapement, and solid-state

types.

The fantastic growth of the field of automatic industrial

control has increased the demand for new and more versatile

devices to perform the basic electrical switching functions

required. The use of time-delay relays has grown rapidly to

keep pace with the demand for the basic function which they

can perform: that of obtaining a predetermined delay from one

switch operation to another.

Time-delay relays perform in a manner quite similar to a

standard relay in that they have contacts that open and close

when power is applied and removed from the input terminals.

The basic difference is that a delay is incorporated into the

contact opening or dosing. Time-delay relays are used in a wide

range of applications: from determining how full your coffee

cup will be when you put a dime in a vending machine, to shutting

off the cutting oil on a milling machine.

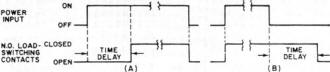

The most popular time-delay relay is the delay on operate,

or de-energization, in which the normally open load switching

contacts transfer at a predetermined time after power is applied

to the input. The contacts drop out immediately upon removal

of the input power (Fig. 1A).

Often a time delay on release, or de-energization, is required.

In this case the normally open load switching contacts operate

immediately when the input power is applied and remain in this

position as long as the input power remains "on". Upon removal

of this power the timing begins, and after a predetermined delay,

the contacts drop out (Fig. 1B).

Several variations on these two basic timing modes are used,

such as interval "on", automatic recycle, combined "on" and

"off" timers, and sequence timers. Many of these can be made

by simple connections of the two basic types.

A selection of typical solid-state time-delay

relays, many of which provide an adjustment for the amount of

delay provided.

Factors to Consider

There are many types of time-delay relays available which

will provide the timing action desired, including thermal. motor-driven,

pneumatic, RC circuit, solid-state, slugged, hydraulic, and

escapement.

There are many factors which must be considered when choosing

one of these time-delay relay types. Consideration should be

given to how each fulfills the following criteria: accuracy,

reset time, repeatability, load-switching capabilities, price,

life, mounting configurations, size, length of delay, temperature

effects, and adjustable or fixed time delay.

Also, various time-delay relays have certain peculiarities

in their operation which should be determined in order to select

the type that will do the job reliably and economically, Some

of these peculiarities are covered below.

Thermal Time Delays

The basic operation of this timer takes advantage of the

difference in the thermal expansion of two metals. A bi-metallic

element is placed in close proximity to a heating element, and

when power is applied the bi-metal deforms and closes or opens

a contact. The time required for the contact to operate is generally

determined by the physical characteristics of the bi-metallic

strip and the amount of power applied to the heating element.

Thermal time-delay relays are usually used where a time delay

on energization is required and the accuracy of the time-delay

period is not critical. One manufacturer states an over-all

accuracy of ± 30% for a miniature or octal plug-in timer, with

delays available from 2 to 180 seconds. Another manufacturer

gives accuracies of ± 20% from 0.75 to 1 second, ± 15% from

1 to 4 seconds, and ± 10% for delays up to 360 seconds. This

is also an octal plug-in type time-delay relay.

Contact forms are usually limited to s.p.s.t., N.0. or N.C.

with ratings that normally do not exceed 5 amperes, 115 volts

a.c, resistive (100,000 operations). Since the thermal time

delay uses the I2R heating effect, the device is

somewhat sensitive to input voltage variations. Voltage variations

of ± 10% will change the delay period approximately ± 5%.

The biggest drawback to the thermal time-delay relays is

their long reset time (the time required for the contacts to

open and to achieve an appreciable percentage of the nominal

delay time on the succeeding cycle of operation). This reset

can be as long as 50 to 200 percent of the operate delay in

order to achieve 80% of the nominal delay period on the next

cycle.

One thermal-delay relay manufacturer recommends the use of

an auxiliary relay to overcome this reset time problem. This

unit uses two sets of contacts, one that closes at the end of

the heating interval which pulls in the auxiliary relay and

interrupts the input power. The cooling interval then begins,

after which the second set of contacts drop out completing the

load-switching circuit. Using this method, approximately 85%

of the nominal operate time is achieved on the succeeding cycle.

Most of the better known thermal time-delay relays are of

the plug-in type and range in price from $2 to $20.

Fig. 1. (A) Delay on energization. (B) Delay

on de-energization.

Pneumatic or Air-Operated

The term "pneumatic" (meaning air-operated) immediately indicates

the basic principle of operation of this type of time delay.

A mechanism is used in which a controlled amount of air under

pressure is displaced from one place to another. (This can be

a unit isolated from the surrounding air, in which the air is

displaced from one chamber to another, or where the air is drawn

from or dispelled into the atmosphere.) A typical unit uses

a diaphragm, a coil, a plunger, and an orifice. When power is

applied to the coil. the plunger (which is mechanically tied

to the diaphragm) is drawn into the coil. The rate of plunger

movement is controlled by the rate of air escape from the diaphragm,

which is controlled by the orifice adjustment. When a predetermined

position is reached, a set of contacts operate as a result of

the plunger movement.

The pneumatic time-delay relay has been in use for 25 years

and has a well-established reputation in heavy industrial applications.

Several manufacturers have units available which lend themselves

to these types of application. They are available for control-panel

mounting, have screw terminals, and are designed for use in

severe industrial environments. This type of time delay is available

as an adjustable unit: some with time-calibrated dials and some

with screwdriver-slot adjustments. The repeat accuracy is usually

± 10% and the reset time is approximately 25 milliseconds (this

reset also applies in case of power interruption).

Units are available in both time delay on energization,

delay on de-energization, and also with both of these functions

packaged in the same enclosure. Some can be converted in the

field from delay on energization to de-energization by a simple

mechanical change. Contact ratings are available up to 20 amperes,

120 V a.c., 60 Hz, resistive (100,000 operations life).

Time-delay periods are available from 0.2 second up to 30

minutes from one manufacturer and 0.050 second to 3 minutes

from another. The temperature range of operation is in the area

from -50° C to +65° C. Supply voltages of 6 V a.c. to 550 V

a.c., 60 Hz and 6 V d.c. to 250 V d.c. are available. Input

power requirements range from 5 to 8 watts. Prices range from

$18 to $100.

Many of the pneumatic units are fairly

large due to the space required for the mechanical mechanism,

although some smaller versions are also available with lower

contact ratings (10 amperes) and shorter delays (180 seconds)

at a higher cost. Pneumatic delays can cause a problem in application

where a dirty atmosphere exists. Any clogging of the orifice

will cause changes in the delay period.

Motor Driven

A synchronous motor is normally used in motor-driven

timers to drive a gear train which controls the load-switching

contacts. When power is applied, the movement functions until

a predetermined time has elapsed, at which time the output contacts

are switched. This timing method depends upon the input line

frequency for its basic accuracy, in a manner similar to a standard

12-hour, 120-V a.c., 60-Hz clock. The majority of these timers

use a magnetic clutch in conjunction with the clock movement

which serves the function of engaging the movement when power

is applied, and allowing it to reset when the power is removed.

The unit is reset by a return spring when the clutch is released.

The time-delay period is set on these units by a pointer

on the front or top of the relay (this may be continuously adjustable

or in increments). A second pointer is usually used to indicate

the elapsed time. The setting accuracy of the continuously adjustable

timers is generally ± 0.5% of full-scale, and the repeat accuracy

is ± 1% of full-scale, or better. The reset time is proportional

to the time required to reset the spring-loaded mechanism and

will be less than 500 milliseconds, depending on time setting

relative to full-scale.

Motor-driven time-delay relays

are available in both delay on energization and delay on de-energization.

The load contacts of the delay on de-energization operate immediately

when power is applied to the clutch and removal of clutch power

starts the timing interval. When this interval is completed,

the contacts drop out. The delay on de-energization will reset

when a momentary power loss occurs.

Delay lengths of

5 seconds to 60 hours are available from one manufacturer and

5 minutes to 5 hours from another. Life ratings of these timers

range from 500,000 operations for one manufacturer to a contact

life rating of 5 million operations for another. Life is usually

limited by clutch failure rather than contact life. Input power

ranges from 5 to 15 VA, including clutch coil and motor. Contact

switching ratings up to 15 amperes continuous are available.

Most of the units available are for 120/240-V a.c., 60-Hz operation.

D.c. units are not generally available. The temperature range

of operation is -20°C to +50°C. Prices range from $5 to $50.

The majority of the motor-drive time-delay relays have

some kind of adjustment feature, some of which are for front-panel

mounting, with a knob to set the time-delay period and are intended

for industrial control-panel use. Others are available with

pointers that can be set to adjust the timing in increments

and are not intended for applications requiring front-panel

mounting.

Delay Slug Relays

A time delay

can be produced on a telephone-type d.c. relay by placing one

or more shorted turns around the magnetic circuit (usually the

core) so as to produce a counter-m.m.f. which retards the build-up

of the operating flux, and upon de-energization provides an

m.m.f. to retard the collapse of the flux. This shorted turn.

or turns. is called a slug. Usually it consists of a copper

collar on the core of the relay. In some designs, a copper sleeve

is used over the full length of the core, and the coil is wound

on the sleeve.

The principle of operation of the slug

is as follows: When the relay coil is energized, the flux build-up

passes through the slug and by self-inductance produces an m.m.f

that opposes the coil m.m.f. This opposing m.m.f. delays the

build-up of the magnetic field in the air gap to a strength

that will cause the armature to close. The time delay on drop-out

occurs in the opposite manner. When the relay coil is de-energized,

the field starts to collapse, thus inducing a current in the

slug that provides an m.m.f. oriented so as to sustain the magnetic

field and thus delay the drop-out.

Pickup delays up

to 120 milliseconds and drop-out delays up to 500 milliseconds

can be achieved by the use of slugs. The delay time will vary

due to mechanical wear over life and ambient temperature and

this type is not intended for high-accuracy applications. Slugged

relays are not generally an off-the-shelf item and are available

only on a special-order basis from most manufacturers of telephone-type

relays.

RC Circuit

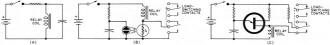

Various methods have been

used to devise time delays using combinations of resistors,

capacitors, and relays. All of these circuits use the basic

principle of charge and discharge of a capacitor and one of

the simplest circuits using this principle is shown in Fig.

2A.

When the switch is closed, the capacitor charges

toward the applied voltage and, after a period of time determined

by the resistance and capacitance (assuming the relay coil resistance

to be very large compared to the resistor), the relay pulls

in. When the power is interrupted the capacitor discharges through

the relay at a rate controlled by the size of the capacitor,

the inductance, and the resistance of the relay coil. This circuit

does not produce an accurate time delay since the time is dependent

upon many factors. Variations in the resistance, the capacitance,

the input voltage, and relay pull-in voltage will cause changes

in tile time-delay period. Delay-period accuracies of ± 30%

are to be expected. The reset time is also long, due to the

high-resistance, capacitor-discharge path. In practice these

timers can be purchased with delays up to 30 seconds and in

both a.c. and d.c. versions.

Variations of this basic

circuit are available which use additional components to increase

the accuracy and speed up the reset time. One popular circuit

uses a neon bulb to sense the voltage level on the capacitor

and a photo-resistive cell to drive the relay. The photocell

offers a low impedance in series with the relay when the neon

bulb fires and causes the relay to pull in (Fig. 2B).

This circuit has several advantages over the previous circuit

in that the neon bulb senses an accurate voltage level and does

not rely on the relay pull-in voltage for the accuracy of the

delay. Also, the relay drops out immediately when the power

is removed, and the timing can be reset with another set of

contacts across the capacitor if desired.

This circuit

is used in several commercially available time-delay relays.

The units are generally adjustable (a potentiometer is used

in series with the resistor) , and the enclosure is all octal

plug-in type. The accuracy of this unit is usually stated as

± 10% over a limited temperature range. Relay outputs on these

timers are usually d.p.d.t., 5-ampere, 120-V a.c, resistive.

Solid-State

The latest entries into the

time-delay relay field are the solid-state types. There are

presently two basic types available using entirely different

principles of operation. One manufacturer is marketing a relay

that uses an accurate oscillator and a counter to perform the

timing function. An output from this oscillator is initiated

when power is applied and is fed into an amplifier circuit.

This amplifier shapes the pulses and reeds them to a magnetic-core

counter. When a predetermined count is reached. the output load

switching contacts are operated through a logic circuit. The

time delay period is determined by the logic and by how many

counters are used after the oscillator.

This time-delay

relay is intended for applications where a high degree of accuracy

is required (± 2 %) . The standard operating voltage is from

18 to 82 V d.c, It has either a relay or a solid-state output

and requires 0.4 sec to reset the delay to the stated accuracy.

Enclosures are available with the popular plug-in feature or

with hook solder terminals and a side mounting bracket. This

unit is expensive as time-delay relays go and sells for $100

or more.

The most popular circuit used in solid-state

time-delay relays employs the RC charge principle, mentioned

previously. The reason for the popularity of this method stems

from the use of the unijunction transistor.

The unijunction

transistor has the inherent ability to offer a high input impedance

to the capacitor voltage until a predetermined voltage is reached.

At this point the device fires and discharges the timing capacitor.

The circuit of Fig. 2C can be used to illustrate this

operation. When the switch is closed, the capacitor charges

at a rate controlled by the RC product. At a voltage level controlled

by the unijunction transistor, the capacitor discharges through

the relay coil and causes the relay to operate. This pulse is

only momentary and a set of relay contacts serves to latch in

the relay.

The unijunction circuit has several advantages over the neon-bulb

circuit in that the firing level is proportional to the input

voltage. Therefore, any input voltage variations are compensated

for by a proportionate change in firing voltage. Other devices

call be added to this circuit to overcome some of the deficiencies

of the previous circuits. Zener diodes are added for better

compensation of time changes due to input voltage variations.

An SCR can be added to give the relay more pull-in and hold-in

power.

Fig. 2. (A) RC circuit may be used to provide

time delay. (B) Neon bulb and photocell or (C) unijunction transistor

may be used.

The circuit shown in Fig. 2C also has the drawback that the

capacitor will discharge through the relay coil immediately

if the power is interrupted and this causes the relay to pull-in

momentarily. The addition of an SCR eliminates this problem.

Line Transients

One problem peculiar to the solid-state

time delays has been that of line transients, particularly on

time-delay relays used on 120-V a.c. line voltage. These transients,

or momentary overvoltage conditions. are common on a 120-V a.c.

line. They can be produced from a wide variety of conditions

including lightning striking the line, switching of inductive

loads on the line, or making and breaking of the transformer

input supplying the time-delay relay. These transients are usually

not a severe problem because they do not contain much energy.

Solid-state time-delay relays used on a 120-V a.c. line

normally employ a silicon rectifier at the input in order to

produce the required d.c, voltage for time-delay operation.

This rectifier is susceptible to the energy contained in these

transients if the voltage is allowed to exceed its reverse rating.

Two methods are commonly used in better solid-state units to

suppress these transients. One method is the use of a controlled-avalanche

rectifier for this input rectifier. When the reverse input voltage

exceeds the rectifier reverse voltage, the device avalanches

and dissipates the transient energy. Special selenium breakdown

devices are also used which can withstand even more energy.

Transient problems are better understood now than in the past

and adequate protection can be provided.

Since solid-state

time delay relays use transistors in the timing portion, and

transistors have long life, a very reliable timer can be built

using these devices. :Many of the units available have an integral

relay for load switching; typically, d.p.d.t., 10-ampere, 120-V

a.c. resistive. In this case the life is limited to the life

of the relay, usually10 million mechanical operations.

Several manufacturers market an all-solid-state timing module

to drive an external load-switching relay. In this case, the

timer life is nearly infinite and is very useful for applications

where high cycle rates are experienced.

Types Available

Solid-state units are available in fixed delays,

internal potentiometer adjustable delays, and external resistor

adjustable delays. The external resistor can be a potentiometer

mounted remotely and wires run to the delay unit.

A wide range of mounting configurations is available, including

screw-terminal dust covers, plug-in types, hermetically sealed

military types, and panel-mounted types. Units are available

in d.c. voltages from 12 to 100 V d.c. and 24 to 240 V a.c.,

60 Hz and require approximately 3 watts of power. The timing

range is usually limited to delays from 0.10 second to 5 minutes

on commercially available units. Delay accuracy varies from

one manufacturer to another and can be as good as ± 5 % over

the temperature range from -40°C to +55°C, and a voltage range

of ±10%.

Several manufacturers are marketing knob-adjustable

solid-state time-delay relays with time-calibrated dials. The

reset time varies, but is usually fast-from 40 milliseconds

to 100 milliseconds - depending upon the circuit configuration.

Time-delay relays are available in both delay on energization

and on de-energization. (The delay on de-energization requires

an auxiliary source of power during the delay period to hold

in the load switching relay and cannot be used for a momentary

power failure delay.)

The solid-state time-delay relays

are available in small enclosures and range in price from about

$10 to $60.

STEPPING RELAYS

There are two types

of driving mechanisms used in stepping relays (often called

stepping switches): the indirect and the direct.

When

the armature-pawl combination acts directly on the ratchet under

the power of the electromagnet, the device is said to be directly

driven, as shown in Fig. A. When the pawl acts on the ratchet

wheel from force stored in a drive spring, the mechanism is

said to be indirectly driven. An example of this method is shown

in Fig. B. The indirectly driven system is the most commonly

used. The spring-driven system is more consistent in performance,

more efficient, and capable of faster stepping than the directly

driven type, besides having a longer operational life.

In an indirectly driven unit, when the proper voltage and

power is applied to the motor magnet coil, the armature is attracted

and holds the drive spring in the "cocked" position. When the

coil is de-energized, the energy stored in the drive spring

pushes the pawl against a ratchet wheel tooth, causing the wiper

assembly to take a step. Repetitive pulses will cause the switch

to take as many steps as the number of discrete pulses received.

The length of time the circuit is closed (and opened) in a series

of fast pulses is critical.

Self-interrupted operation,

such as shown in Fig. B, is used to step the switch rapidly

from one point to another without the use of discrete pulses

from outside sources. In this method, a circuit is closed to

the coil through a set of interrupter contact springs that are

opened by an arm of the armature before it is fully seated.

Breaking the coil circuit causes the armature to fall away,

driving the wiper assembly one step and simultaneously reclosing

the interrupter contacts. The armature is again attracted, re-cocking

the switch and thus causing a re-opening of the interrupter

contacts. The switch runs self-interruptedly until the circuit

is again opened.

Posted 9/9/2011