|

April 1959 Popular Electronics

Table

of Contents Table

of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

Servomechanisms are all around

us in the form of electronically actuated controls for our cars, stepper motors

in our ink jet printers, overhead garage door openers, and anywhere else you can

identify where a combination of electricity and mechanics operates with some form

of positional sensing and feedback. The author of this circa 1959 article entitled

"What Is a Servomechanism" in one instance declares a control circuit with a human

operator being part of the operation as an "open loop," but I contend that the human

element is actually part of the loop and therefore constitutes a component which

closes the feedback loop. A human-in-the-loop system can still be considered an

electromechanical entity. Those of us who operate

radio-controlled model airplanes, boats, cars, etc., are very familiar with

servos for moving control surfaces as commanded by the transmitter's joystick position.

Through visual observations and hand inputs to the transmitter, we close the servo

loop that controls the R/C airplane, helicopter, drone, car, boat, etc. Servomechanisms are all around

us in the form of electronically actuated controls for our cars, stepper motors

in our ink jet printers, overhead garage door openers, and anywhere else you can

identify where a combination of electricity and mechanics operates with some form

of positional sensing and feedback. The author of this circa 1959 article entitled

"What Is a Servomechanism" in one instance declares a control circuit with a human

operator being part of the operation as an "open loop," but I contend that the human

element is actually part of the loop and therefore constitutes a component which

closes the feedback loop. A human-in-the-loop system can still be considered an

electromechanical entity. Those of us who operate

radio-controlled model airplanes, boats, cars, etc., are very familiar with

servos for moving control surfaces as commanded by the transmitter's joystick position.

Through visual observations and hand inputs to the transmitter, we close the servo

loop that controls the R/C airplane, helicopter, drone, car, boat, etc.

After Class: What is a Servomechanism?

By Harvey Pollack By Harvey Pollack

Before the age of electronics, machinery was controlled directly by the hands

of the operator-hands which would shift a gear, pull a lever, or apply a brake.

Today's machinery is controlled by the push of a button or the twist of a knob,

and many measurements and decisions are made automatically by electronic circuits.

Wherever electronics and machinery work together we are apt to find some kind of

servomechanism in operation.

An automobile driver is the human counterpart of a servomechanism - he watches

and controls a machine. As he steers his car along a winding highway, he constantly

makes small corrections on his steering wheel to keep the car on the road. His eyes

measure distances, his brain makes simple decisions, and his arm muscles exert corrective

pressures on the steering wheel. A servomechanism performs the same function, but

it is faster, more sensitive, does not make mistakes in judgment, and operates continuously.

The definition of a servomechanism recommended by the Feedback Control Committee

of the American Institute of Electrical Engineers is: "A feedback control system

in which the controlled variable is mechanical position." Let's examine, in practical

terms, what that means.

The ABC's of Servos

Consider our automobile driver again. From his reactions we can determine the

requirements of a machine that could capably replace him.

Before the start of the drive, he accepts the fact that the road divider must

always remain from six to fifteen inches from his front left wheel if he is to navigate

the highway turns and straightaways safely. During the trip, he must be aware of

the separation that actually exists during every instant of time. Then he must compare

the actual separation between his wheels and the white line with the desired separation

that was initially stipulated. This might be called the error in the car's path

at that instant. Once the error is determined, he must then dictate a corrective

order to his arm muscles so that they can apply a force in the proper direction

to eliminate the error.

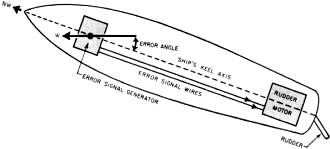

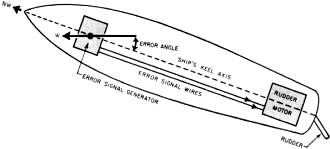

Fig. 1 - Example of an "open-loop" type servomechanism.

It serves practically as an antenna rotating mechanism for TV installations. "Open-loop"

refers to the need for a human control element in the servomechanism system.

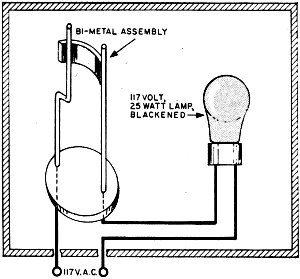

Fig. 2 - A course control system as used in ocean-going

vessels is a typical application of a "closed-loop" type of servomechanism. Once

the course has been set, no further human guidance or readjustment is needed for

operation.

If we now analyze these steps, we can state the ABC's of servos. A servo must:

(A) Accept instructions that tell it what should be done; (B) Be aware of the actual

conditions that exist at every instant; (C) Compare what is being done with what

should be done; (D) Dictate orders that will correct the error noted by this comparison;

and (E) Energize some mechanism that can follow these orders.

Open-Loop System

Consider the antenna rotator servo shown in Fig. 1. This is referred to

as an "open-loop" servo system because a human operator is required as one of the

links in the ABC chain. The knob at the TV set is secured to a disc in contact with

all the contact points save the one that happens to be in line with the notch cut

in the disc. A permanent spring contact is made to the disc as shown.

Suppose the TV viewer decides that he would like to rotate his antenna from position

2 to position 1. He turns the knob to position 1, bringing the notch in line with

contact point 1 at the same time; but when he does this, contact point 2 touches

the disc and feeds electrical energy to the motor through commutator segment 2.

Each time the commutator arrives at a new segment, the power flows uninterruptedly

to the motor until it reaches segment 1, when the circuit is again opened and the

motor stops, leaving the mast in the desired position.

Note that the human operator must dictate the necessary instructions to the servo

by rotating the positional switch to the desired setting. In a "closed-loop" system,

a human operator is totally unnecessary.

Closed-Loop System

Imagine that the course of a ship is to be due west and that its gyro-compass

has been set for this direction. Along comes a gust of wind or an ocean current

that tends to swing the prow of the ship to the north. The gyro-compass, of course,

continues to point to the west as the boat turns under it, thereby producing an

error angle between itself and the boat's axis.

If the compass is coupled to an electrical generator of a suitable type which

can feed an error signal proportional to the error angle to a rudder motor at the

stern, then the rudder will swing over to an extent that will just correct the deviation

from the proper course.

The error angle represents the comparison between what is actually being done

and what should be done. Corrective orders are dictated by means of an electrical

signal that varies with the amount and direction of the error; this order signal

then energizes a rudder control motor which makes the necessary correction in course.

Thermostat Control

When you set the thermostat of your oil-burner, you have issued instructions

that it keep the house at, say, 70°F. The bi-metallic strip inside the thermostat

retains "awareness" of existing temperatures by bending toward an electrical contact

as the house cools. When the contacts finally close as the temperature goes below

70°F, the thermostat issues a corrective signal in the form of a current to the

relay of the oil burner.

If you would like to experiment with thermostatic control to get the "feel" of

the ABC's of servos, you can pick up an old fluorescent starter and use it as the

base for a thermostatically controlled chick incubator or a transmitter crystal

oven. Pry up the four sheet-metal fingers that secure the disc base to the metal

casing and lift out the whole inside structure. If a capacitor is present (some

starters omit the capacitor), clip it out by cutting its leads close to the disc

base.

Fig. 3. - Modification required to convert a fluorescent

lamp starter into a sensing element of a thermostatic control circuit. "Before "

view (left) shows internal assembly of starter after protective glass is broken.

"After" view (right) illustrates modification made to the contact to enable use

of the starter as a thermostatic switch.

Wrap a single layer of cloth around the glass tube, place it between the jaws

of your vise, and apply pressure gradually until the glass just cracks. Be careful

not to damage the bi-metallic assembly that is now exposed. The concave portion

of the curved strip is brass and the convex section iron. Since brass has a higher

coefficient of linear expansion than iron, this bar will tend to straighten when

heated, i.e., it is normally off and makes contact when its temperature rises.

To reverse this action, bend the free vertical bar as shown in Fig. 3 so

that the inner brass face of the strip barely touches the bent bar at room temperature.

The temperature at which contact will be broken will then depend upon the extent

to which the strip presses on the vertical bar. This can easily be adjusted experimentally

by further bending either to the right or left.

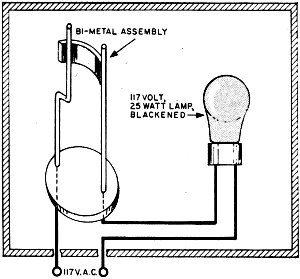

An incubator or oven thermostat may be set up easily using the circuit of Fig. 4.

The "heater" is a 25-watt incandescent lamp blackened with candle-black or sprayed

lightly with flat black lacquer. The enclosure in which it is placed should be fairly

well insulated so that it retains its heat.

Fig. 4 - Wiring and installation of modified bi-metallic

element in a homemade experimental thermostatically controlled incubator or crystal

(oscillator) oven.

Posted September 2, 2020

(updated from original post on 12/4/2013)

"After Class" Topics

|