|

June 1955 Popular Electronics

Table of

Contents Table of

Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

This article from a 1955

issue of Popular Electronics discusses the state of the art of ultrasonic

transducers and equipment that uses them. Amazingly, of all the applications

that are mentioned, one is glaringly missing. Author Louis Garner, Jr., mentions

using ultrasonic transducers for measuring material thickness, detecting flaws

on and within materials and assemblies, cleaning by ultrasonic scrubbing,

soldering*, and motion detection for security systems. The missing items of

course is sonar

(sound navigation and ranging). The U.S. Navy was using sonar during World

War II, although it had been in development a couple decade earlier - similar to

radar's evolution. 15 - 20 kc (kHz) frequencies were typical in the day. Modern

ultrasonic cleaners use up to 40 kHz, and high resolution sonars run into the

low MHz. Oh, also missing is

ultrasound imaging like what is used for prenatal and other internal

imaging, but that was still in the experimental stage in the mid 1950s. BTW, I

worked with sonar systems as an electronics technician at the

Westinghouse

Oceanic Division in Annapolis, Maryland, in the 1980s.

* See the interesting information on

ultrasonic soldering on the S-Bond Technologies website.

Silent Sound

By Louis E. Garner, Jr. By Louis E. Garner, Jr.

Powerful sound waves radiated by mechanical transducers find a multitude of valuable

applications in industry.

Ultrasonic Instruments, industry's newest tools, are used for such varied tasks

as measuring the wall thickness of metal tanks, checking forging ingots for flaws,

locating defects in railroad tracks, soldering aluminum and other hard-to-solder

metals without fluxes, protecting plants and offices against intruders, and for

machining metals and other hard materials. Ultrasonic cleaning machines are used

for everything from tiny laboratory instruments to aircraft parts, from gears to

delicate optical lenses.

Ultrasonic refers to those sound frequencies above approximately fifteen thousand

cps. The upper limit is very high - into the megacycles (millions of cycles per

second). Since ultrasonic signals are not audible, they are frequently called "silent

sound."

A transducer is a device for changing energy from one form to another. Earphones

and loudspeakers are transducers, for they serve to change electrical energy into

acoustic energy. Transducers are the important links between the electronic circuits

which produce, amplify, and measure ultrasonic signals and the materials which are

being processed or tested by the ultrasonic instruments.

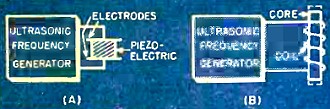

Fig. 1 - Two basic transducer designs are shown above. Drawing

(A) has a crystal element and drawing (B) a magnetostrictive core. Actual element

movement in both cases is extremely small.

Fig. 2 - A simplified block diagram of industrial ultrasonic

equipment.

Fig. 3 - These plates illustrate the efficiency of ultrasonic

cleaning. Both were soiled with a black grease pencil. The clean plate was cleaned

in two seconds using a solvent activated by ultrasonics.

This photo shows the violent agitation of a liquid excited by

the curved ultrasonic transducer immersed in the solution.

Fig. 4 - Pulses of ultrasonic energy are reflected by flaws and

displayed on a cathode ray tube.

Fig. 5 - Illustration of a method for examining odd-shaped metallic

pieces for flaws using ultrasonic waves.

A General Electric ultrasonic generator is shown being used at

the Holley Carburetor Co, to clean a jet engine fuel control part.

Using a portable ultrasonic flaw detector to check a railroad

track rail for defects or cracks.

Fig. 6 - This sketch illustrates the operation of the ultrasonic

alarm system.

Industrial ultrasonic transducers are generally made up either of piezoelectric

materials or magnetostrictive elements. A piezoelectric material is a substance

whose physical dimensions change when a voltage is applied to it, producing a mechanical

force. The converse is also true in most cases - when mechanical force is applied

to the material, an electrical voltage may be generated. The mechanical force may

be pressure or a twisting or bending action. Typical piezoelectric materials are

quartz crystals, Rochelle salts, barium titanate, and certain other ceramics. Crystal

and ceramic microphones and phonograph cartridges are everyday examples of piezoelectric

transducers.

A magnetostrictive element is a core of magnetic material surrounded by an energizing

coil. When a piece of material is magnetized, the individual molecules of the substance

"line up" in order. This results in a minute change in the material's length. When

ultrasonic electrical energy is supplied to the coil, the core is first magnetized

in one direction, demagnetized, then magnetized in the opposite direction. Since

the core length changes with each magnetization, the result is a change from electrical

energy (in the energizing coil) to mechanical movement (lengthening and shortening

core). Nickel and its alloys are frequently used as cores for magnetostrictive elements.

A simplified block diagram for industrial ultrasonic equipment is given in Fig.

2. With modifications, this diagram applies to almost all of the ultrasonic instruments

in current use. The "heart and brains" of the equipment are the electronic circuits

which generate and control the high frequency electrical signals. In the case of

measuring instruments, there may be circuits producing, detecting, and amplifying

ultrasonic signals. There will be one or more transducers to convert the high frequency

electrical energy into ultrasonic vibrations in the material being tested or processed.

Where measurements are involved, there will be an indicating device.

Cleaning Parts: One example of the capabilities of ultrasonic

instruments is given by the sample plates in Fig. 3. Both of these deeply serrated

metal plates were soiled with a black grease pencil. The clean one was given a 2-second

rinse in a solvent activated by ultrasonic vibration; the other was given a rinse

two and half times as long in the same solvent, but without activation. It required

10 minutes for complete cleaning without ultrasonics - 300 times as long as with

activation. In some cases, the transducer may be shaped to focus or to concentrate

the ultrasonic vibrations. The frequencies used for ultrasonic cleaning range from

as low as 15 kc. to 1 mc. and higher.

The efficiency of an ultrasonic cleaner results from two actions : the vibratory

motion given to the liquid cleaner by the ultrasonic energy; and the action called

cavitation, a "cold-boil" which results when the vibrating liquid is torn into small

vacuum pockets. As these pockets form and collapse, they create strong localized

pressures, bombarding the parts being cleaned from every direction, and blasting

off dirt and other foreign matter.

Thickness Measurement: To measure the thickness of the metal

in a large tank, or in a ship's hull, where only one side can be reached, is not

impossible with an ultrasonic thickness gauge.

Several methods may be used but portable instruments frequently employ the principle

of resonance. A transducer, driven by an electronic oscillator, is placed in contact

with one side of the material to be tested. The ultrasonic wave travels through

the material in a narrow beam and is reflected by the opposite surface. At certain

frequencies the transmitted wave and the reflected wave will reinforce each other,

resulting in an increase in the intensity of the wave in the material. The frequencies

at which the reinforcement occurs depend on the thickness of the material and the

velocity of sound through it. Since the velocity of sound is constant for a particular

material, the determination of the fundamental frequency of resonance (where reinforcement

occurs) is a reliable measure of the thickness of the material.

Inspection and Test: The "echo" principle is used in industrial

test instruments wit h ultrasonic vibrations taking the place of radio or audible

sound waves. The reflectoscope may be used for checking large metal billets for

defects, locating flaws in castings and forgings, checking parts for interior defects,

evaluating welds, and checking the physical dimensions of metal parts where only

one end or side may be reached.

In operation, a transducer is placed against one end of the piece to be tested

and "beams" pulses of ultrasonic energy through the material (see Fig. 4). These

pulses travel to the end of the piece and are reflected back to the transducer,

where they are detected. If there are cracks or holes in the piece, these flaws

also cause reflections. The transmitted signal and all of the reflected pulses are

displayed as "pips " on the screen of a cathode-ray tube. The relative distance

between t he first pip and succeeding pips on the tube's screen is proportional

to the distance between the point where the transducer is placed and the distance

to the flaws or to the end of the piece. Thus, the instrument shows both defects

and their approximate location. If the piece has an irregular shape, it may be immersed

in liquid for testing, as shown in Fig. 5. The liquid transmits the ultrasonic vibrations

from the transducer to the piece.

Ultrasonic Soldering: Soldering aluminum is difficult because

oxide films form so rapidly. Success depends on clean metal surfaces and strong

flux. After the soldering is completed, every trace of flux must be removed to prevent

corrosion. Ultrasonic soldering instruments, however, have simplified this job.

A magnetostrictive transducer, operating at about 20 kc., vibrates the metal and

literally rips up oxide films, allowing the solder to form a strong union with the

heated metal.

Plant Protection: Most modern industrial plants are fairly well protected, either

by full time guard staffs or by various electronic burglar alarms, including "electric

eye" systems, electronic fences, closed circuit television observation stations,

and similar protective devices. But only ultrasonics can guard against the intruder

who hides inside during working hours and works by night.

A small hand tool is used to make a soldered fillet in a grounded

aluminum chassis.

The operation of an ultrasonic alarm system is illustrated in Fig. 6. High frequency

sound waves are "broadcast" by the transmitting transducer, just above the door.

These ultrasonic signals bounce off the floor, ceiling, walls and furniture, literally

filling the room with silent sound. The signals are picked up by the receiving transducer.

As long as the transmitted and received signals are the same frequency, the room

is secure and protected. But if anything should move within the room, the frequency

of the signal picked up by the receiving transducer changes slightly. Electronic

circuits are constantly comparing the frequencies of the transmitted and received

signals, and when the small frequency change occurs, an alarm is sounded.

Truly, the surface has barely been scratched as far as potential applications

of ultrasonic equipment are concerned. We may expect to see it used in every branch

of industry, in the home, in business, and in medicine. Ultrasonic drills have been

used in dentistry (see "Dentistry - the Painless Way," Popular Electronics, November,

1954.) Ultrasonic vibrations have been used to accelerate the pollination of plants.

Laundry work has been done with ultrasonics. In the future, "smog" may become a

thing of the past as ultrasonics is used to coagulate and precipitate stoke and

dust.

Future applications will be covered in other issues of Popular Electronics.

Posted July 19, 2019

|