|

November 1949 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

John T. Frye was an

electronics service technician long before he began writing techno-dramas like "Mac's

Radio Service Shop" and "Carl

& Jerry." His expertise and real-world experience evidenced itself in the

wide variety of situations and subjects covered in the stories. If you have

never read any of them, I whole-heartedly suggest that you sample a few (or

listen to one of my podcast readings of them). In

this article from a 1949 issue of Radio-Electronics magazine, Mr. Frye

discusses what was evidently a reluctance on the part of service men to acquire

and/or use printed service data when troubleshooting and/or aligning radios,

televisions, tape recorders, etc. The attitude of some elitists was that if you

needed to consult documentation that it was evidence of your ineptness; you were

not a worthy electronics technician. More than one episode of Mac's Radio

Service Shop had owner Mac McGregor admonishing young Barney about wasting time

during troubleshooting by not consulting the service data sheets he stocks in

the shop. Even if a shop owner could not afford the elite service literature

from

SAMS Photofacts or a couple others, the electronics magazines of the era

usually published at least one

Radio Data Service Sheet in each monthly issue.

Service Data Technicians and Money

By John T. Frye By John T. Frye

A lie, some wag has said, is a last resort with men, but with women it is a form

of first-aid. This masculine reluctance to a mischievous expedient is commendable;

but when a radio technician insists upon applying the same attitude toward the use

of radio service data, he is being short-sighted, money-wasting, and just plain

stupid. Nevertheless, the sad truth is that there are many who turn to their shelves

of service data for help only after they have exhausted every other possibility

in their attempt to repair a receiver.

This is really puzzling. Any modern shop is certain to have a complete set of

service information on hand. It can be quickly demonstrated to even the most stubbornly

doubtful that radios can be serviced much more quickly, pleasantly, and efficiently

through the use of such data. Every radio shop owner knows that minutes shaved off

the time needed to repair a set is just like money in the bank. In spite of all

this, there are far too many shops in which the books do not have that well-thumbed

look that radio service manuals should have.

Possibly there are a few rare cases where the technician is one of those boys

who bull-headedly waste hours searching a catalog for an item before looking it

up in the index, merely because he likes doing things the hard way; but these, surely,

are in the minority. It seems likely that the rest do not get the maximum benefit

from their libraries simply because they have not formed the habit of using them

properly.

Many, when they started servicing, felt that they could not afford to buy service

manuals; the servicing procedure established necessarily excluded their use. Later,

when they were able to obtain service data and did so, their servicing routine had

become so firmly set that they could not - or at least did not - change it to take

full advantage of the great help offered by their books.

The publishers of modern radio service data spend thousands of dollars trying

to make their products of the utmost assistance in servicing every set that comes

into the shop. The material is intended to be used all of the time, and is crammed

with information calculated to be useful to the novice and the old-timer alike,

but the only way in which any service technician can extract the full amount of

benefit from it is to build his service procedure around its continuous use.

When to Use Data

Fig. 1 - Under-chassis view of receiver. Call-outs show location

of all parts. Courtesy of Howard W. Sams & Co.

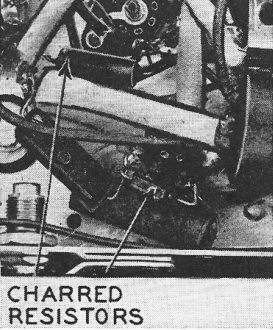

Fig. 2 - Charred parts are easy to spot.

The set of service manuals on the shelf is as important as the

instruments below. Courtesy John F. Rider, Publisher

The time to slide a manual from the shelf is the minute you decide which set

you are going to tackle next. First, take a quick glance at the description of the

receiver and at the diagram or picture in the book that shows the tube layout. You

may be able to locate a similar diagram in the set, but at any rate it is much more

comfortable to study the picture laid out on the bench instead of standing on your

head trying to read an upside-down sketch pasted in the darkest, most cobwebbed

corner of the cabinet.

This preliminary survey can tell you a lot. It will reveal whether you are working

with an a.c.-d.c, set, a transformer job, or one of those electronic mules that

employ a high-voltage series-filament winding on an autotransformer. It will show

whether you should expect superheterodyne selectivity or are dealing with a t.r.f.

receiver - something that cannot be told with a casual glance in this day of four-tube

"supers," subchassis-mounted i.f. transformers, and padded oscillator tracking circuits.

It will also reveal whether the tubes are where they should be; and if you tell

an old-timer you have never wasted time working on a set in which the customer had

switched a couple of tubes, you will make him question either your veracity or the

amount of time you have been in the service game!

If your preliminary examination shows that surgery is indicated and that the

chassis must be removed from the cabinet, take another look at your data. See if

instructions for chassis removal are given. Some manuals give detailed information

on this subject wherever it is needed - and believe me, it is needed often in opening

up some of these ultra-modern creations with hidden chassis bolts, concealed hinges,

and trick cabinet designs. Without such "open sesame" instructions, you can waste

half an hour fumbling around the outside of one of these sleek-looking, seamless

armchair models like a monkey trying to get into a plastic coconut.

When the set has been extracted from the cabinet and is resting on the bench

in front of you, your service data stands ready to lend a hand, no matter what method

of troubleshooting you prefer. If you use a signal-tracer, the diagram will tell

you exactly where to touch your probe, and the stage gain of each section is plainly

indicated. Any deviation from the normal can be detected at once, and the exact

point at which this deviation begins can be pinned down.

On the other hand, if you prefer resistance measurement, the correct resistance

from every tube socket connection to the common ground is given; and if voltage

measurement is more to your liking, the proper operating voltage at nearly every

point of the circuit is indicated.

The diagram is right there in front of you. Only a service technician who has

wasted time checking and rechecking a puzzling low-resistance condition by unsoldering

the leads of every capacitor that might be involved - only to find the trouble caused

by a shorted bypass hidden away inside an i.f. shield - can appreciate the value

of working with a diagram. The intelligent use of printed data removes the wasteful

lost motion from radio servicing.

The service data publishers are keenly aware that time is money in servicing,

and they have worked out many time-saving features. Take, for example, an all-wave

set in which only one band is out of order. Obviously the fault lies in one of the

components used exclusively on this band. But if you have ever watched a poor technician

mumbling to himself and making circles in the air with his finger like a man trying

to describe a circular staircase, while he attempts to thread his way through the

maze of a multibank band-change switch, you can realize. how he should appreciate

a data sheet showing an entirely separate circuit diagram for every position of

the switch.

The value of photos

Another set Of sheets gives photographs of every set taken from different points

of view and with the various parts identified by numbered or lettered "call-outs"

right on the picture. Fig. 1 shows a bottom-chassis view of this nature. To show

how it helps, notice Fig. 2, which is a picture of the same receiver shown in Fig.

1. If you will look closely you will notice - as did the technician - that the resistors

numbered R12 and R14 in Fig. 1 are badly charred in Fig. 2. Inasmuch as the positive

filter capacitor leads attach to the opposite ends of R12, and R14 connects between

one side of the line and the plate of the rectifier tube, it is not hard to diagnose

the trouble here: the output section of the filter capacitor has shorted, causing

both the filter resistor R12 and the ballast resistor R14 to char. Cutting loose

the output filter capacitor lead and checking it with an ohmmeter quickly proved

this deduction correct.

A glance at the parts list was all that was needed to find the correct replacement

values for Cl, R12, and R14. It was not necessary to locate the parts by tracing

out the circuit diagram. Only seconds were needed to determine exactly what parts

were required. Had the circuit diagram been needed, it was available; but. it is

surprising how many times, when there are visual symptoms of trouble, you can work

directly from the pictures. The beginning radio technician who has some difficulty

in "seeing" a receiver in diagram form is especially grateful for this feature.

Data Helps Beginners

Speaking of beginners, it is an unhappy fact that many fellows try to start into

servicing without purchasing service data. If anyone needs such help, these beginners

do. The veteran technician has a wealth of practical experience to fall back on

when he runs into unusual problems, but the novice feels utterly at sea. The small

successes he has had in locating open filaments and shorted bypasses in AC-DC receivers

stand him in poor stead when he runs into a really tough set. He simply does not

know where to begin. What he needs more than anything else is the wealth of data

on normal operation that a manual presents. A methodical comparison between the

resistances, voltages, and stage gain of the defective receiver and the normal values

of these items as presented in the service data is almost certain to uncover the

trouble.

What is more, the constant use of service data is the best possible way for the

newcomer to become familiar with radio circuits and manufacturing practices. As

he continues to study the diagrams of the sets upon which he is working day after

day, he absorbs, without any conscious effort, a knowledge of what constitutes standard

circuits and normal values for components used in those circuits. Almost before

he realizes it, he finds himself knowing what to expect when he makes a measurement,

and is alert to any abnormality that may be encountered. The constant use of service

data is about as quick a way to learn practical radio as there is.

It is paradoxical that the beginner's need for this material is indicated by

the fact that successful veteran technicians invariably have them. These fellows

could repair any receiver, using only their knowledge of radio theory and their

practical experience; but they are fully aware that they can do the same job in

a fraction of the time when they have the books to help.

Moreover, they know that they will be able to do better work. Take, for example,

the matter of alignment. Even with AM sets it is essential to know the correct i.f.;

the position, use, and order of adjustment of the trimmers; and certain special

information regarding such matters as triple-tuned transformers and a.f.c. circuits,

all of which are plainly set forth in step-by-step fashion. Receivers can be aligned,

after a fashion, without knowing these things, but the resulting performance will

often be short of what it should be.

The man who blindly aligns all i.f.'s at 456 kc is not much better than the one

who maintains you do not really need a signal generator to do radio servicing! But

when you go into FM and TV alignment, service information becomes an absolute necessity.

Another feature technicians new and old can appreciate is the listings of manufacturing

changes. The service technician can frequently improve the operation of a set over

what it was when new. That makes a decided hit with his customer!

Equally helpful is the practice of giving the replacement part numbers of several

different manufacturers for each component. This enables the technician to make

a quick choice from available stock.

If there remains any lingering doubt in your mind as to just how helpful service

data can be, a bout with a defective record changer should remove it. Without servicing

information, you have to trace out the sequence of events that should take place

during the change cycle by observation - and observing the action of a record changer

is about as difficult and nerve-wracking as trying to read a long-winded title on

a whirling phonograph record.

How different all this is when you have service data! You are shown an exploded

view of the entire mechanism that reveals the exact shape and position of every

single part. The change cycle is described in detail. For every possible fault in

the operation of the changer, several possible causes and cures are listed.

The author has no connection with any radio service data publisher, but he is

deeply interested in the future of radio servicing, and he feels that an increase

in the use of service literature is a most important factor in improving both the

quality of, and the profit from radio servicing.

He has no recommendations as to which of the leading service-data publishers

you should patronize. The products of each have some distinctive features not found

elsewhere. The important thing is to own and use at least one of them.

Posted November 22, 2021

|