|

April 1972 Popular Electronics

Table of Contents Table of Contents

Wax nostalgic about and learn from the history of early electronics. See articles

from

Popular Electronics,

published October 1954 - April 1985. All copyrights are hereby acknowledged.

|

It is well known that American

automobile manufacturers really dropped the quality ball in the mid-1970s through

about 1990. Foreign car makers were gaining increased access to domestic markets

with designs that had more efficient engines and transmissions with superior materials

and techniques, and corrosion control was much better than most American cars that

often began to exhibit rust bubbles underneath the paint within a year or two -

particularly in regions where roadways were salted for controlling ice and snow.

People (like me) who bought used cars were leery about a vehicle with more than

70k-80k miles on them because it was almost guaranteed that a major engine or transmission

repair would not be far off. Foreign cars, in contrast, were still going strong

at 100k miles. If you were there, you know of what I speak. I mention that background

to help explain the opening statement in this 1972 Popular Electronics

magazine article describing what could be expected in the near future with electronics

in cars and trucks. A look at the one drawing reveals that by now everything predicted

is now standard equipment even on low-end cars, and of course not many people would

have predicted GPS navigation, Bluetooth-connected tire air pressure sensors, satellite

radio, or even air bags.

Solid State columns: April 1967,

August 1967,

April 1966,

August 1970,

July 1971,

October 1971,

April 1972.

More Solid-State Electronics for the New Cars

What Ford and Chrysler are Offering in their

1972 Lines What Ford and Chrysler are Offering in their

1972 Lines

By John D. Drummond

Part 2

Chances are that the first car you drive with an on-board minicomputer that starts

the engine, optimizes ignition and air/fuel mix, sets safety mechanisms, and gets

ready to shift transmission, will come from Japan or Germany. The reason such a

car is not likely to come from Detroit is that foreign car firms and electronics

companies are cooperating with each other to develop and deliver sophisticated system

packages. The picture on the domestic front is quite different; a lack of good communications

has put the auto men and electronics men at odds with each other.

There is certainly no lack of expertise or ambition in the U.S. The missing ingredients

are cooperation and understanding. But with no clear, enthusiastic agreement, solid-state

electronics in American-made automobiles has only inched along.

It is obvious that any little "blackbox" electronic package integrated into an

automobile must be able to outfox and outlast the hostile environments created by

rough roads, snow, ice, mud, extreme heat, and extreme cold. Otherwise, the highly

practical automobile engineer wants no part of it, according to Charles T. Mulcahy,

a Ford Motor Co. Engineer. He goes on to say, "If the engine won't start, the car

won't go; if the engine starts and the car is inoperative, the car won't move."

But consider this: the little black box has guided man to the moon and back in

spectacular form. Solid-state devices contain no inherent wearout mechanisms. In

fact, thanks to their proven reliability, solid-state devices and systems are perhaps

the only practical and economical way to realize safety, environmental cleanliness,

and the convenience required for tomorrow's automobile.

The Pressure is On. With enforcers

breathing down their necks, the auto makers are necessarily devoting most of their

efforts to solving the problem of reducing exhaust emissions and developing passive-restraint

devices to comply with Federal regulations. So, Detroit has had to lay aside, at

least for the present, development and implementation of such exotic things as a

single-wire multiplexed system that replaces the maze-like electrical network wiring

harness; radar-based anti-collision and braking systems; central processor to control

antiskid braking; electronic fuel injection; and speed and transmission controls. The Pressure is On. With enforcers

breathing down their necks, the auto makers are necessarily devoting most of their

efforts to solving the problem of reducing exhaust emissions and developing passive-restraint

devices to comply with Federal regulations. So, Detroit has had to lay aside, at

least for the present, development and implementation of such exotic things as a

single-wire multiplexed system that replaces the maze-like electrical network wiring

harness; radar-based anti-collision and braking systems; central processor to control

antiskid braking; electronic fuel injection; and speed and transmission controls.

The auto men are furious over this stringent Federal legislation. Ernest S. Starkman,

a General Motors vice president, explains that considerable progress has already

been made toward reducing air pollution from automobiles. But pressure for further

reductions is a consequence of impatience with the progress being made in the state

of the air in our urban environments.

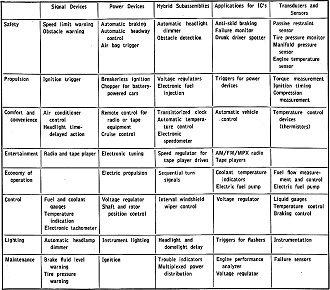

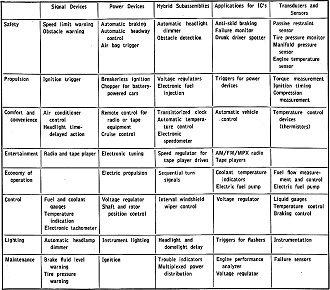

This diagram shows various items being offered by Ford, though not all of them

are available on all Ford cars. The systems shown are all-electronic.

Whatever the impetus, the electronics industry has a golden opportunity to work

with Detroit in meeting Federal pollution standards. The electronics men feel that

solving both the pollution and passive-restraint problems are within their bailiwick.

Presently, however, the auto men are more preoccupied with grappling with the pollution

problem. But some electronic devices are showing up in Detroit's new cars.

Possible Applications for Solid State in

Automobiles Possible Applications for Solid State in

Automobiles

Ford's Better Ideas. Typical of what is being marketed are the

electronic controls in Ford's 1972 line. Not all of the items (see illustration

below) are available in any one model. But they are available in various combinations

on all Ford-built cars.

Among the offerings are safety braking for skid control to prevent the wheels

from locking up and skidding should the driver attempt a panic stop on wet, slippery

or icy roads. The system utilizes an electronic computer that goes to work only

during an emergency situation that could cause the wheels to lock. The computer

receives speed information from a wheel sensor through a digital-to-analog (D-A)

converter that translates it to a dc voltage before it is fed to a differentiator

and data analyzer. The differentiator output is compared with a reference signal

representing the coefficient of friction of the road surface from the data analyzer.

The comparator output is fed to a logic circuit which determines the amount of braking

required and simultaneously activates a power stage which controls braking.

Automatic speed control is another offering. Using an electronic memory, this

system automatically maintains a constant speed in response to the driver's command.

When the car reaches cruising speed, the driver presses a button. The desired speed

is then "memorized" and maintained up- and downhill and on the straightaway without

the driver having to touch the accelerator. When the brakes are applied, the speed

control is automatically deactivated.

A number of safety features have been put into the system to meet the industry's

standards. For example, a redundant brake-disable feature is available to protect

against a defective or poorly adjusted brake switch. Hence, if no disabling signal

is received when the brake pedal is depressed, the speed control will automatically

disable when the car's speed drops to about 8 miles below the speed that was set

into the computer.

A distributor modulator is a third offering. Designed primarily as an exhaust

control device, the modulator precisely controls spark advance at speeds in the

25-32-mph range, assuring more complete fuel combustion.

Diagram of Ford's new anti-skid braking system installation.

Computer is located behind glove compartment. (Photo courtesy of Ford Motor Company.)

There is also an rpm limiter available. It is used primarily in Ford cars equipped

with high-performance engines and manual transmissions. This over-speed limiter

keeps the engine from exceeding a safe maximum rpm limit.

Chrysler's Coming Through. Keeping up with their Detroit rivals,

the Chrysler people are pushing electronics in their ignition systems, a safety

braking system, and automatic temperature control.

The electronic ignition, which eliminates breaker points, looks pretty much like

a conventional system except for a control unit between the distributor and the

ignition coil and the addition of a dual ballast resistor. The electronic circuitry

is activated by a pickup coil and is used to control a switching transistor that

opens and closes the primary circuit of the ignition coil.

The great advantage of the breakerless system is lower tune-up cost. A by-product

of the electronic circuitry, claims Chrysler, is that ignition timing and dwell

angle are more accurately controlled than would be possible with conventional breaker

points. The end result is better exhaust emission control.

Like the systems employed by GM and Ford, Chrysler's safety brake relies on a

logic computer to activate a pressure modulator to decrease the amount of hydraulic

pressure being applied to the brake at the wheel which is about to lock up or skid.

Where it differs from the competition is that the Chrysler system prevents front

or rear wheel lockup for shorter straight-line stopping distances. It is claimed

that the four-wheel safety braking system makes any driver better than an expert

driving a standard-equipped car in straight-ahead braking applications. However,

as Chrysler engineers are quick to point out, it cannot correct for skids initiated

by bad driving, such as when entering a curve too fast.

The 1972 Chrysler and Imperial model autos are equipped with a second-generation

automatic-temperature control which uses an all-electronic solid-state amplifier

to totally control the system's performance. In prior systems, Chrysler employed

a combination of vacu-electronic components to automatically adjust temperature.

This marks the first time that Chrysler Corp. has used a totally solid-state system

employing IC's, transistors, and diodes to control a major system.

The Coming Tide. It is obvious from the foregoing that, in spite

of foot-dragging and lack of cooperation, some inroads are being made by the electronics

industry in Car City. What is also obvious is that, if and when a team effort is

finally made, great things are in store for the average American-made automobile.

Let us hope that the animosity gap existing between the car makers and the electronics

industry narrows soon and creates the friendly conditions needed to bring about

cooperation.

Posted March 14, 2024

(updated from original post on 7/10/2017)

|

What Ford and Chrysler are Offering in their

1972 Lines

What Ford and Chrysler are Offering in their

1972 Lines