Press Release Archives:

2026 | 2025 |

2024 |

2023 |

2022

2021 |

2020 |

2019 |2018 | 2017 | 2016 |

2015

Content is copyright of company represented. Page format, custom text and

images are RF Cafe copyright - do not distribute. Note: Posting of press releases costs $100 each for non-advertisers.

January 20, 2026 - San Mateo, California - Since 2005, San Francisco Circuits

(SFC)

has been a trusted U.S. provider of advanced PCB manufacturing and assembly solutions

for R&D innovators, prime contractors, and integration experts. SFC

has published a white paper entitled, "PCBA Press Fit Connector Reliability: Strain Thresholds and Best Practices,"

to help inform you on issues that can mean the difference between success and

failure.

Press fit connectors are common in high-density PCB designs - powering 5G infrastructure,

electric vehicles, aerospace systems, and advanced medical devices. Their ability

to deliver high I/O counts without the heat risks of soldering makes them indispensable

for modern electronics.

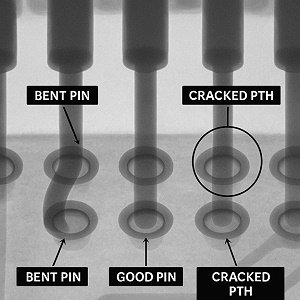

But here's a hidden risk: If strain during insertion isn't properly managed,

it can lead to latent solder joint cracks, fractured plated through holes (PTHs),

or deformed pins. These failures often escape detection during testing and only

surface in the field - causing warranty returns, costly recalls, or even mission-critical

system outages.

In this post, we'll cover how stress impacts PCB reliability, safety thresholds,

and how to overcome these challenges in your application.

Understanding Press Fit Strain

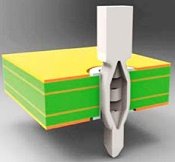

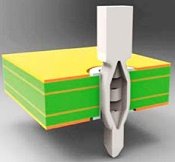

Press fit technology uses an interference fit, where connector pins are pressed

into PTHs with near-zero clearance to form a tight mechanical and electrical bond.

A controlled force (up to 600 lbs for a 60-pin connector) drives this process, causing

the PCB to flex. This flexure generates strain that can crack solder joints, PTH

barrels, or deform pins, threatening reliability in high-stakes applications like

aerospace or medical devices. For instance, a medical client could face costly MRI

control board failures due to BGA cracks near press fit sites, underscoring the

need for precise strain management. Press fit technology uses an interference fit, where connector pins are pressed

into PTHs with near-zero clearance to form a tight mechanical and electrical bond.

A controlled force (up to 600 lbs for a 60-pin connector) drives this process, causing

the PCB to flex. This flexure generates strain that can crack solder joints, PTH

barrels, or deform pins, threatening reliability in high-stakes applications like

aerospace or medical devices. For instance, a medical client could face costly MRI

control board failures due to BGA cracks near press fit sites, underscoring the

need for precise strain management.

Types of Press Fit Connectors

There are two main types of press-fit pins:

- Solid pins, which feature a rigid press-in zone.

- Compliant pins, which have an elastic press-in zone that allows for flexibility

and deformation during insertion.

Both types of press-fits can either be soldered or solderless, depending on the

application (pin count/density, risk of thermal stress during soldering, simplicity

of assembly).

Please visit

San Francisco Circuits website for ... the rest of the story!

San Francisco Circuits serves industries where performance and security converge,

including aerospace & defense, medical devices, industrial & energy, and

advanced communications. The company's technical depth spans rigid, flex, and rigid-flex

PCB fabrication, with expertise in HDI and RF/microwave designs, adhering to IPC,

MIL-SPEC, AS 9100, ISO 9001:2015, and ANSI ESD standards.

For system integrators, every connection matters - including the partner you

trust with your intellectual property and system backbone. San Francisco Circuits

delivers precision-engineered PCBs backed by industry-leading data protection and

mission-level reliability.

Read more on PCB solutions for system integrators on the San Francisco Circuits

website.

About San Francisco Circuits

San Francisco Circuits is a provider of PCB fabrication and assembly, has a dedicated

team specializing in simple and complex PCB fabrication and assembly technologies.

They can produce elaborate and high-quality PCBs in a number of custom and common

layouts. From basic to intricate PCBs–their engineers will meet your PCB fabrication &

assembly needs. The company provides a rare balance between technical expertise

and competitive pricing. And they not only provide high-quality products but also

high-quality customer service at the same time. San Francisco Circuits has been

voted by National Television as the "world's greatest in PCBs" and has demonstrated

experience as a power player in PCB fabrication and assembly.

If you are looking to discuss PCB projects of any size or scope, feel free to

reach out to them via our website (see below).

Contact

Victor Bilandzic

San Francisco Circuits, Inc.

Phone: 1-800-732-5143

Web: www.sfcircuits.com

|

Press fit technology uses an interference fit, where connector pins are pressed

into PTHs with near-zero clearance to form a tight mechanical and electrical bond.

A controlled force (up to 600 lbs for a 60-pin connector) drives this process, causing

the PCB to flex. This flexure generates strain that can crack solder joints, PTH

barrels, or deform pins, threatening reliability in high-stakes applications like

aerospace or medical devices. For instance, a medical client could face costly MRI

control board failures due to BGA cracks near press fit sites, underscoring the

need for precise strain management.

Press fit technology uses an interference fit, where connector pins are pressed

into PTHs with near-zero clearance to form a tight mechanical and electrical bond.

A controlled force (up to 600 lbs for a 60-pin connector) drives this process, causing

the PCB to flex. This flexure generates strain that can crack solder joints, PTH

barrels, or deform pins, threatening reliability in high-stakes applications like

aerospace or medical devices. For instance, a medical client could face costly MRI

control board failures due to BGA cracks near press fit sites, underscoring the

need for precise strain management.