|

June 1969 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

Integrated circuits (IC's)

were newcomers to the world of electronics in 1969. Most people, it is probably

safe to say, had no idea what an integrated circuit (IC) even was. At the time,

many experienced design engineers - perhaps especially experienced design engineers

- had no formal training on the fabrication of integrated circuits. After all, assuming

an engineering student graduated at the age of 22 years old and was in 1969 say,

30 years old, he or she would have begun junior level classes about 12 years earlier

- 1957 for the sake of argument. Given that

Jack Kilby

applied for the patent on his ground-breaking, world's first integrated circuit

in 1959, there is no way those engineers would have had instruction on the matter.

Therefore, articles like this one in Radio-Electronics magazine served

as an introduction to IC fabrication processes. The fact is, even though these days

all engineers take courses on semiconductor physics and fabrication, most will never

need to apply that knowledge any time in their careers. See

Part

1, Part 2,

Part 3,

Part 4.

All About IC's - What Makes Them Tick

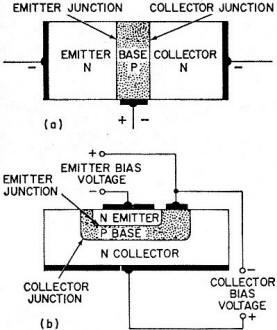

Fig. 1 - Electron and hole movement; forward bias (a) and

reverse bias (b).

by Bob Hibberd

Texas Instruments, Dallas, Texas

Learn how solid-state integrated circuits are made - Part 1

The potential of integrated circuits is so wide that in addition to replacing

similar discrete component circuits, they are responsible for creating a completely

new technology of circuit design.

To get the full implication of integrated circuits, you must have a general basic

understanding of solid-state technology and its application. We'll start with a

general introduction covering the basic principles of solid-state semiconductor

devices. Then we will review the processes used to form the solid-state structures

used in integrated circuits.

Basic Solid-State Principles

In a conductor, electric current flow is a movement of free electrons. The outer

or valence electrons of a good conductor such as copper are so loosely bound to

the atom that at room temperature the thermal energy causes approximately one electron

to detach from each atom and become free to move and result in a current flow when

an electric potential is applied.

Insulators are materials in which the outer electrons are tightly bound to the

atom and no electrons are free to move. Thus, no current can flow when a voltage

is applied.

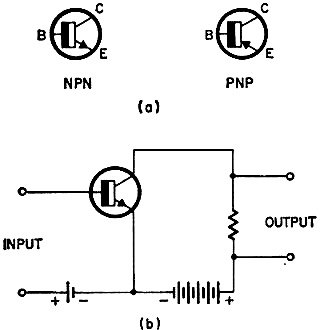

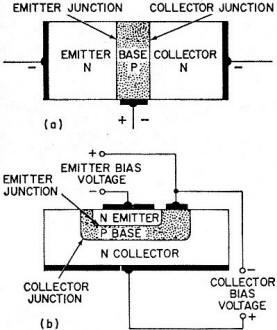

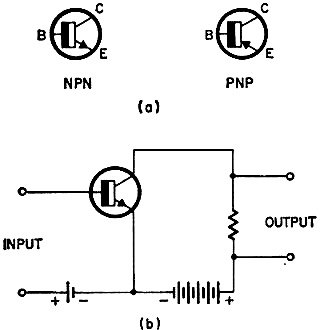

Fig. 2- (a) Diagram of npn, and (b) practical transistor

arrangement.

Between these two major categories is a class of materials called semiconductors.

As the name implies, a semiconductor is a material with conductivity roughly midway

between conductors and insulators. However, a semiconductor is not just a poor conductor;

it has two other very important properties. First, its resistance normally decreases

with increase of temperature, as opposed to conductors such as metals in which the

resistance increases slightly with temperature. Secondly, flow of current in a semiconductor

can be by two mechanisms, either by a flow of negative electrons similar to current

flow in conductors, or by a movement of missing electron sites in the opposite direction.

If an atom has one outer electron missing, a loosely bound electron from a neighboring

atom can jump into it, leaving behind a new vacant site; this in turn can be filled

by an electron from a third atom and so on. It then appears as if the vacant site

has moved. Such vacant sites are called "holes" and since a negative electron is

missing the hole can be considered as a positive charge.

Semiconductor material in which conduction is by a flow of electrons is called

n-type material (n for negative carriers) and material in which conduction is due

to the movement of positive holes is called p-type.

From the viewpoint of monolithic integrated circuits, the most important semiconductor

material is silicon. Silicon has four outer or valence electrons. If we add a small

amount of an impurity element with five valence electrons, such as phosphorus, one

electron per impurity atom will be free and we have n-type silicon. Similarly, if

we add an impurity with only three valence electrons such as boron, there will be

one missing electron or hole per boron atom and we have p-type silicon.

The operation of most solid state devices depends on the properties of one or

more p-n junctions. A p-n junction is a transition from a p-type semiconductor to

an n-type semiconductor within a piece of material. Alone, a piece of n-type or

p-type semiconductor is purely resistive. Reversing a battery connected across it

will reverse the direction of current flow, but will not affect the magnitude of

the current. By contrast, a piece of semiconductor material with a p-n junction

in it has rectifying properties. When the positive terminal of a battery is connected

to the p-type side and the negative terminal to the n-type side, the free negative

electrons in the n-type side are attracted across the junction to the positive contact,

and the positive holes in the p-type side are attracted across the junction in the

opposite direction to the negative contact (Fig. 1-a). This is called the forward

or conducting direction. A high current flows with only a small applied voltage,

and the forward resistance is very low. Now if the battery connections are reversed

(Fig. 1-b) the holes in the p-type side are attracted away from the junction

toward the negative terminal and the electrons in the n-type side are attracted

away from the junction to the positive terminal and so no current flows across the

junction. This is called the reverse or non-conducting direction and no current

flows even with a high voltage applied. (In practice a very small leakage current

does flow, due to free electrons and holes being generated near the junction by

the thermal energy.) So a single p-n junction can be used as a rectifying diode.

Fig. 3 - Common-emitter circuit has both the input and output

common to emitter.

Fig. 4 - Symbols for npn and pnp transistors, and common-emitter

circuit.

An important point to observe is that when forward current is flowing through

a p-n junction (Fig. 1-a) electrons are flowing through p-type material in

which there are normally no free electrons, and also some holes are flowing through

n-type material. The electrons are said to have been injected across the p-n junction

into the p-type material. It is this situation that leads to the operation of the

junction transistor.

The NPN Junction Transistor

A junction transistor consists of two p-n junctions formed in a piece of semiconductor

material with a very small separation, only of the order of one-tenth of a mil.

A diagrammatic npn transistor with its operating voltages is shown in Fig. 2.

The first n-type region is called the emitter since it emits or injects electrons

into the center p-type region which is called the base. The second n-type region

is called the collector as it collects electrons from the base region. The junction

between emitter and base is called the emitter junction and that between collector

and base the collector junction. As mentioned above, in practice, the width of the

base region is only of the order of a tenth of a mil.

The collector junction is biased with a high voltage in the reverse direction

(positive to the n-type collector, negative to p-type base) and so, considering

the collector junction by itself, no current flows across it. Now suppose the emitter

junction is biased in the forward direction (negative to the n-type emitter and

positive to the p-type base). A forward current flows across the emitter junction

and electrons are injected into the p-type base region. If there were no voltage

applied to the collector junction, these electrons would flow out of the base contact,

but with the collector reverse-biased, as soon as the electrons in the base region

flow near the collector junction, they are attracted across it by the positive potential

on the collector side. Thus most of the current crossing the emitter junction continues

on across the collector junction. The current across the emitter junction was produced

by a very low forward voltage (less than 1 volt) and this current now flows in the

collector circuit, which is biased with a voltage, providing power amplification.

As the electrons injected across the emitter junction flow through the base region,

some of them fill holes in the p-type material. Thus the electron current crossing

the collector junction is slightly less than the emitter current. The ratio of collector

current divided by emitter current (IC/IE) is called the current

transfer ratio and is designated by the symbol

α, i.e.

α =

(IC/IE). A typical value for

α is

0.98.

A current equal to the difference between the emitter current and the collector

current flows in the base lead so that IE = IC + IB,

with α

= 0.98, the base current IB will only be 0.02 times the emitter current.

In the description of transistor action above, current through the collector

is controlled by the emitter current, and the arrangement is called the common-base

circuit since the base electrode is common to both input and output circuits. A

more convenient arrangement is with the input fed to the base and the emitter common

to both input and output as shown in Fig. 3. This is called a common-emitter

circuit. The collector current is now effectively controlled by base current IB

and the ratio of collector current to base current has a high value, equal to

α /

(1 - α).

If α

= 0.98 as above, (IC/IB) =

α /

(1 - α)

= 49

Thus we have a current gain from the input to the collector of 49 times, and

if the collector current flows through a load resistance to give a voltage output

from the collector, a voltage gain results.

The PNP Junction Transistor

A pnp structure operates in a similar way to the npn transistor. There are two

points to observe. First, to bias the emitter junction in the forward direction,

the emitter must be made positive with respect to the base. To bias the collector

junction in the reverse direction, the collector must be made negative with respect

to the base. Secondly, the p-type emitter injects positive holes into the n-type

base region, and they are subsequently attracted across the collector junction by

the negative potential.

To represent the transistor graphically, the symbols shown in Fig. 4-a are

used. The emitter is shown as an arrow pointing in the direction of positive current

flow (opposite to the direction of electron flow). This device in a common-emitter

circuit is shown in Fig. 4-b.

Fig. 5 - Crystal-pulling device uses seed crystal rotating

in poly crystalline silicon.

So far we have shown the importance of the pn junction. The technology of fabricating

solid-state devices and integrated circuits has evolved around the development of

methods of producing pn junctions in silicon material. The following sections are

devoted to a general description of the basic processes involved in solid state

technology.

Silicon is a metallic element with a light gray appearance. It occurs in nature

as silicon dioxide (silica) and as various silicate compounds. To prepare silicon

for solid state devices, there are two main requirements. First, extremely high

purity is required, with unwanted impurities down to a level of one part in 1010.

Second, for a pn junction to operate as described earlier, the silicon must have

a continuous regular crystal structure, and so the silicon must be converted into

what is called single crystal form.

The first step in the preparation of semiconductor grade silicon is to reduce

silica by heating it with carbon (coke) in an electric furnace. The resulting silicon

is about 98% pure. The next step is to purify this material. It is converted to

a compound such as a halide (silicon tetrachloride) which is purified by repeated

distillation. Then the purified halide is converted back to silicon by hydrogen

reduction. In this process, the silicon is deposited onto the surface of a high-purity

silicon rod, building it up to a diameter between 1 and 4 inches. Using this chemical

method of purification, we get the required purity level of one part in 1010.

The silicon deposits onto the rod in polycrystalline form and must now be converted

to single crystal form. The process generally used to produce single crystal silicon

for transistors and integrated circuits is called crystal pulling. The general arrangement

is shown in Fig. 5. Solid polycrystalline silicon is placed in a pure quartz

crucible supported inside a translucent quartz chamber, through which a flow of

an inert gas such as argon is maintained. The quartz crucible is located in a graphite

susceptor, which is heated by RF induction. When the silicon is all molten, its

temperature is lowered to a value just above its melting point, and a seed crystal

- a small piece of single crystal silicon - is lowered until it just enters the

melt. The seed crystal is rotated (about 60 rpm) and slowly raised (about 1 inch

per hour), growing larger as more silicon solidifies onto it. Typical pulled silicon

crystals are cylindrical in shape between 1 and 2 inches diameter by about 12 inches

long.

The dopant to give n-type or p-type silicon is added to the silicon during the

initial melting process so that the crystal has required conduction properties.

Epitaxial Growth

In the fabrication of solid state structures, we often want to form a thin film

of single crystal silicon with certain conduction properties on the surface of another

silicon slice. The process used is called epitaxial growth and films up to a few

tenths of a mil can conveniently be formed. The starting slice must be single crystal

with the required crystal orientation and is called the substrate.

Fig. 6 - Step-by-step photoresist process for removing selected

silicon dioxide areas.

Fig. 7 - Fabrication of a silicon npn transistor using the

diffused planar process.

Hydrogen gas is bubbled through a volatile silicon compound such as silicon tetrachloride,

causing it to vaporize. The mixture of vapor plus hydrogen is fed to a reaction

chamber where the silicon substrate slice is heated to about 1200°C. The silicon

tetrachloride dissociates and silicon is deposited onto the surface of the heated

slice to form the epitaxial layer, which grows at about micron (0.04 mil) per minute.

The conductivity of the epitaxial layer is controlled and arranged to be either

p-type or n-type by introducing the requisite amount of a suitable dopant vapor

into the hydrogen stream with the silicon tetrachloride vapor.

Solid State Diffusion

Solid state diffusion is a process involving the movement of n-type or p-type

impurity atoms into the solid silicon slice. To do this, the slice is heated to

a high temperature, between 800 and 1250° C, in the presence of a controlled

density of the impurity atoms.

In practice, the process is often carried out in two steps. The first step consists

of heating the silicon slice in the impurity dopant vapor to form a high concentration

of dopant on the surface. This step is called deposition. The slice is then removed

to another furnace where it is heated to a higher temperature so that the dopant

atoms on the surface move, or diffuse, into the silicon. This is called the diffusion

step.

If a p-type impurity is diffused into the surface of an n-type slice such that

the density of p-type atoms then exceeds the original density of n-type atoms in

the slice, the surface will be changed the p-type and a p-n junction will be formed

a small distance in from the surface where the density of the diffuse p-type atoms

equals the original n-type density.

Convenient diffusant impurities for silicon are boron as a p-type impurity and

phosphorus as an n-type impurity.

A most important and significant fact is that a layer of silicon oxide on the

surface of a silicon slice will prevent the diffusion of certain elements, including

boron and phosphorus, into the silicon. Also important is that silicon oxide can

readily be removed from the surface of the silicon slice by etching with a hydrofluoric

acid solution without etching the silicon. Thus, if we oxidize a slice of silicon

by heating it in a flow of oxygen to form a layer of silicon dioxide on the surface,

and then remove the oxide from selected regions by etching, we can arrange to diffuse

impurities into these selected regions only. This selective diffusion is the basis

of all silicon monolithic integrated circuit fabrication - it allows the simultaneous

formation of a number of separate components in a single slice of silicon.

The selective removal of silicon dioxide is carried out by a photolithographic

process using photoresist material. The several steps in the process are illustrated

in Fig. 6. After oxidation (a), the oxidized surface of the slice is coated

with a thin layer of photoresist lacquer (b). This is an organic substance which

polymerizes when exposed to ultraviolet light, and then, in that form it resists

attack by acids and solvents. A photographic mask, with opaque regions located where

it is required to remove the silicon oxide, is placed over the slice and illuminated

with ultraviolet light (c). The photoresist under the opaque regions of the photomask

is unaffected and can be removed with a solvent, the exposed photoresist remaining

in the other regions. The slice is baked to harden the photoresist and then immersed

in a hydrofluoric acid solution to etch away the silicon oxide where it is not protected

by the polymerized photoresist (d). Finally the photoresist is removed from the

surface (e), and the slice is thoroughly washed. It is now ready for diffusion which

will only occur through the openings (sometimes called "windows") in the oxide.

This complete photoresist process must be repeated each time the silicon oxide is

selectively removed.

The Planar Process

The combination of oxidation, selective oxide removal and diffusion forms the

basis of the planar process, which is now firmly established as the basic process

of solid state technology. The sequence of processes used to fabricate a silicon

planar n-p-n transistor will be described in some detail. The processes are carried

out on whole silicon slices, about 1.5-inch diameter by 10 mils thick. Each slice

normally contains a large number of individual device patterns, and at the end of

the slice processing it is cut up into individual wafers.

Referring to Fig. 7, an n-type silicon slice is oxidized (a) and windows

for the base diffusion are opened in the oxide (b) by the photoresist process as

in Fig. 6. Boron is used as the p-type impurity for the base diffusion. Boron

tribromide, a liquid, is vaporized, the vapor mixed with nitrogen, and passed over

the silicon slice heated to a temperature of 850° C. During this process boron

is deposited onto the surface of the silicon. The slice is then transferred to another

furnace and heated at 1150°C in a flow of nitrogen for a sufficient time (about

one hour) for the boron to diffuse in and form the p-n junction at the required

depth. During the latter part of this diffusion, steam is mixed with the nitrogen

so that a new layer of silicon dioxide forms on the surface of the diffused region

(c). In addition to diffusing down into the silicon, the boron also diffuses sideways,

and so the p-n junction is formed under the oxide and is protected against surface

contamination. This is a very important feature of the planar process. A typical

base diffusion depth is 0.1 mil.

Fig. 8 - Semiconductor structure of MOS transistor and symbol

for p-channel type.

The slice is now prepared for the emitter diffusion by etching windows in the

new oxide grown over the base region (d), using the identical photoresist process

as before. To form the n-type emitter region, phosphorus is diffused in. Liquid

phosphorus oxychloride is vaporized and passed over the slice at 1000°C. This

is usually a single step diffusion, and for the latter part of the cycle, steam

is again introduced to form silicon oxide on the surface (e). The emitter diffusion

depth is about 0.06 mil, resulting in a base width between the collector and emitter

junctions of 0.04 mil.

The next process is to form metallized contacts to the base and emitter regions.

Once more the photoresist process is used and contact windows are opened in the

silicon oxide (f). Aluminum is now evaporated onto the whole surface of the slice,

and a fourth photoresist sequence carried out with a "reverse" contact photomask

to remove the aluminum from everywhere but in the contact windows. The aluminum

remaining in the contact windows is then alloyed to the silicon to form a low resistance

contact (g).

Finally the slice is cut into individual transistor elements by scribing between

the rows of elements and breaking into wafers. The individual wafers are assembled

into transistor units by fusing down to a header, which forms the collector contact,

and bonding connections to the base and emitter contact areas (h).

It will be seen that all of the above processes are carried out on the top surface

of the slice, and the three regions of the transistor - the emitter, base and collector

- all come to this same plane surface and hence the name "planar." By changing the

photomask details only, any size and shape can be given to the diffused regions,

and so any desired element can be produced with the same basic diffusion processes.

MOS Transistors

Fig. 9 - Nine steps used in the fabrication of the metal-oxide-silicon

transistor.

So far, we have discussed only the "bipolar" junction transistor - bipolar because

two types of carrier, the free electron and the positive hole, are involved in its

operation. A more recently developed transistor, the metal-oxide-semiconductor field

effect transistor (the MOS transistor) is of considerable importance in integrated

circuits. The basic operation of this transistor is quite different from that of

the bipolar transistor. In it, a conducting channel is induced between two very

closely spaced electrode regions by increasing the electric field at the surface

of the semiconductor between the electrodes.

The basic structure is shown in Fig. 8. The two electrode regions, called

the source and drain, are formed by a p-type diffusion into an n-type silicon wafer.

Between the source and drain are two pn junctions back to back, p1n and

np2. With a voltage VDS applied between the source (positive)

and the drain (negative), the np2 junction is reverse-biased and so no

current will flow from source to drain. If now the gate electrode over the space

between source and drain is made sufficiently negative with respect to the source,

holes are attracted to the surface of the n-type region and cause it to change to

p-type. Then we have two p-type electrodes with a p-type channel joining them and

so a current can flow.

The steps in the fabrication of an MOS transistor are shown in Fig. 9. An

n-type silicon slice is oxidized (a) and a photoresist sequence used to form a window

in the oxide for the complete device (b). Now a new thin layer of oxide is formed

in the window by oxidation in steam (c) and a second photoresist process used to

open windows for the source and drain diffusion (d), and boron is diffused in (e).

The thin oxide is then removed by immersing the slice in a hydrofluoric acid solution

(f). Next a new very pure oxide layer is grown over the device region (g) and contact

windows for the source and drain opened by another photoresist process (h). Finally

aluminum is evaporated over the whole slice and removed everywhere but in the source

and drain contact windows and in the gate electrode region by a fourth photoresist

process (i).

The thickness of the pure oxide under the gate electrode is only of the order

of 1000 angstroms and the spacing between the source and drain is typically 0.3

mil. The whole structure can be fabricated in an area about 3 mils by 1.5 mils and

this makes the MOS transistor very suitable for use in integrated circuits where

a high density of elements is desired. The fabrication of the MOS transistor in

integrated circuits will be discussed in detail next month. R-E

Posted September 4, 2018

|