|

November 1967 Radio-Electronics

[Table of Contents] [Table of Contents]

Wax nostalgic about and learn from the history of early electronics.

See articles from Radio-Electronics,

published 1930-1988. All copyrights hereby acknowledged.

|

During the early

era of color television, much editorial

ink was

spilled on the topic of x-radiation emitted from the high voltage power supplies

within. This 1967 Radio-Electronics magazine article appeared toward the

end of the problem. Those of us who were around for the excitement remember being

told as children "Don't sit so close to the TV; it'll ruin your eyes." The ignorant

among us thought the admonition was because focusing so close-up would be bad training

for eye muscles. The real reason was danger of absorbing too much ionizing x-radiation

from the high voltage vacuum tubes. Achieving bright, vibrant color with early tri-color

cathode ray tubes (CRTs) required blasting the red, green, and blue phosphorescent

dots on the back of the display glass with ultra high energy electrons. Accelerating

them to such extraordinary bias voltages of 25 kV or more generated the

x-rays. TV owners were told

to not turn up the brightness any more than necessary, but of course we all twisted

that control on the back of the set until a beautiful picture was presented even in

a brightly lit room. Eventually, better CRTs were developed and high voltage power

supplies got heavy shielding around them, but part of the "solution" was to assure

that most escaping x-rays were directed toward the bottom of the set, away from

living beings. See also

TV X-Rays Are Back,

X-Rays from

TV Sets - Are They Harmful?, and others from the list at the bottom of the page.

What You Should Know About X-Ray Radiation in TV Sets

By David Lachenbruch By David Lachenbruch

High-voltage tubes in a color receiver can produce soft X-rays, but you can easily

protect yourself

Do X-Ray emissions from color television sets pose a potential hazard to the

public or to service technicians?

This question was widely publicized in recent months - but in the public press,

at least, the answer seems to have gotten lost. The entire color-TV X-ray issue

was brought to public attention as the result of a design error by a major manufacturer

and the subsequent field modification of about 90,000 large-screen receivers. The

General Electric incident touched off intensive TV testing activities by the Department

of Health, Education and Welfare, by state and regional health authorities and by

television manufacturers.

It resulted in the introduction of several bills in Congress for federally enforced

standards and testing of high-voltage electronic devices. Hearings were held on

the subject by two House subcommittees and one Senate committee, and it appears

that one such bill will be passed in the next session of Congress.

The incident also prompted a wave of official concern for the safety of viewers

and service technicians from possible X-ray overexposure.

Both the G-E problem and the X-ray scare in general are surprising in view of

two well-established facts: (1) From the very birth of the TV industry, manufacturers

have been especially vigilant on the subject of X-rays. (2) At the voltages employed

in color television receivers, X-radiation can easily be stopped with very simple

shielding.

A Tiny Leak

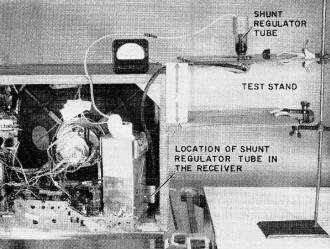

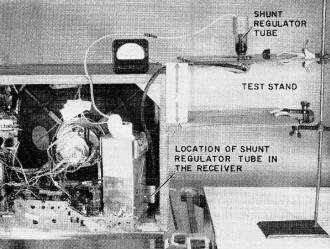

Experimental setup used to survey radiation from shunt

regulator tubes. A G-E KC chassis was used as the power supply. Location of socket

on chassis made radiation measurements almost impossible so an adapter and test

jig were used. The tube was mounted 7 inches above a sheet of Royal Blue X-ray film.

Courtesy National Center for Radiological Health

The G-E trouble - one of those things that "just could not happen" - resulted

from a change in chassis design for the 1967 models, which went into production

in spring 1966. The shunt regulator tube was sunk into a well in the chassis. After

a large number of these receivers were in the field, G-E discovered in routine retests

that excessive amounts of X-radiation were leaking downward in a fingernail-size

arc through the tube socket. The size of the leak was so small that it had previously

escaped detection.

Since G-E's 1967 KC chassis lacked external shielding below the shunt regulator

tube (although the leakage in many models was stopped by the cabinet), the company

instituted a crash program to develop a family of direct-replacement tubes which

incorporated an extra measure of internal shielding, for modification of these sets

in the field. A widespread effort resulted in location and modification of almost

all of the questionable receivers through simple tube replacement.

The vast majority of the original G-E shunt regulator tubes (designed for the

KC chassis) on dealers' and distributors' shelves were also taken off the market

and replaced by the new heavily shielded types. However, there are still a few around,

on shelves and in tube caddies. For each one returned, to a General Electric distributor

- regardless of the make of the tube - G-E pays a bounty of $5, plus a free exchange

of a direct-replacement substitute.

Needless to say, no one should have any of the questionable tubes in his possession,

and a search for any of these obsolete tube types may be both emotionally and financially

rewarding:

Obsolete type Replacement

6EA4

6EH4

6EF4

6EJ4

6LC6

6LH6

What about color-TV sets in general? Are there X-radiation dangers, hazards or

pitfalls? Here a background review may be helpful.

The National Council on Radiation Protection and Measurements (NCRP), a government-chartered

independent nonprofit organization, has recommended that X-radiation levels for

TV sets not exceed 0.5 milliroentgen per hour (mR/hr) at a distance of 5 centimeters

(about 2 inches) from the set's surface. This figure was not established for the

protection of individuals (who can take exposures many times greater without ill

effect) but for protection of the "population" at large, to help keep general background

radiation levels down.

Any X-ray exposure from sets meeting this standard represents a very small percentage

of the natural "background" radiation that is part of our everyday environment -

in effect, it is negligible. The NCRP figure is considered, by NCRP and by radiation

scientists, to be very conservative. In fact, it is one-fifth the amount of radiation

permitted from TV sets by Underwriters' Laboratories until September, 1967, when

UL changed its standard to conform with NCRP recommendations.

Following the G-E disclosures, American television set manufacturers, under the

aegis of the Electronic Industries Association, conducted exhaustive X-radiation

tests of more than 500 color TV receivers, covering chassis types representing approximately

95% of all color sets in use.

The results showed that, under normal operating conditions, not one set radiated

above the 0.5-mR/hr standard. In fact, the vast majority measured considerably less

- many of them below the capabilities of the measuring equipment used. Tests of

Japanese receivers sold in the United States showed similar results.

X-rays are produced whenever a beam of electrons strikes some material at a relatively

high velocity, as in a vacuum tube. Accelerating voltages of at least 10 or 15 kV

are required before any significant quantity of X-rays is emitted. Because of the

absorption of X-rays by glass tube envelopes, there is normally no significant escape

of radiation from tubes unless voltages are in the range of 20 kV or higher. Thus,

in a color television receiver, there are two or three potential sources of X-rays

- the picture tube, the high-voltage power supply and the shunt regulator tube (if

one is used).

Radiations produced at these voltages are known as "soft" X-rays - the type which

does not significantly penetrate body tissue. The amount of exposure to X-rays depends

on the amount of voltage, duration of exposure and distance from the source of the

X-rays. The use of heavily leaded glass envelopes on picture tubes, and shielding

around the other two high-voltage tubes, keeps X-rays well below the permissible

figure in most normally operating color sets.

Clean Bill

In all inquiries and tests to date, color receivers (except the G-E sets in question)

have received a clean bill of health under "normal operating conditions." This brings

up two questions of utmost significance to the technician: (1) What are "abnormal"

operating conditions and how can they be avoided? (2) Even if there is no danger

to viewers, how can the technician be assured that he is not receiving excessive

X-ray exposure?

Fortunately, the answers to both questions involve only common-sense precautions

and the following of normal servicing instructions - instructions which should be

heeded anyway to avoid shock and implosion danger and repeated set failure.

Specifically as to the second question: There are no concrete data to show that

the technician - even the worst, most careless technician - can receive dangerous

exposure. But, by the same token, there is no proof that he can't.

Since relatively little is still known about the cumulative effects of soft X-rays,

the technician has an important responsibility to his customer (and himself) regarding

those "abnormally operating" sets. These are receivers operating at above the high

voltage specified by the manufacturer or without proper shielding. Many color sets

with a recommended voltage of 25 or 26 kV can be operated as high as 33 kV (although

they may fail prematurely).

At the level of voltages used in color sets, X-ray emission increases roughly

in proportion to the square of the voltage increase. Though manufacturers' tests

showed that many sets operating at too-high voltages quickly developed circuit failures

(and those which continued operating emitted only moderately excessive radiation),

don't tempt fate.

The rules to be followed in home or shop repair, for safety of both viewer and

technician, are listed in most service manuals. Those which can keep X-ray exposure

below the safe minimum deserve special emphasis:

1. Be sure that all service personnel are familiar with the subject of radiation.

This can be covered by having them read this article.

2. To avoid possible exposure to radiation and shock hazard, never apply power

to the receiver unless the high-voltage compartment is completely assembled with

the door closed and all other original factory-installed shields are in place. These

shields include any additional shielding on the outside of the high-voltage compartment,

shields surrounding the high-voltage rectifier tube or the shield inside the plastic

tube cap. If a shield is missing from an incoming set, replace it at once as a standard

servicing procedure.

3. High voltage must never be adjusted to exceed the factory-specified amount

with the brightness and contrast adjusted to minimum (no illumination on the screen).

Refer to the manufacturer's service manuals for specific instructions. If the high-voltage

check indicates a malfunction or improper adjustment, correct this fault before

any other service procedure - such as picture-tube setup, yoke adjustment or troubleshooting

- is performed. It's important to use an accurate and reliable high-voltage meter.

Meters should be calibrated at regular intervals.

4. Whenever tube replacement is necessary, replace regulator tube, picture tube

and high-voltage rectifier tube only with the types specified for the specific receiver.

Refer to the tube-location label attached to the inside of the receiver, or the

service manual, since the tube being replaced may be an incorrect type previously

installed by someone else.

5. In troubleshooting procedures, never apply a line voltage exceeding the manufacturer's

specifications. Many technicians use a variable stepup transformer to let a set

"cook" until the suspected component fails. Never resort to this practice in servicing

a: color set.

6. In the customer's home, check the power-line voltage at the wall outlet to

make sure it doesn't exceed the input voltage rating of the receiver. If the power-line

voltage is excessive, ask the power company to adjust the line voltage to ,the proper

level. Or else set the transformer tap as specified by the manufacturer so that

the receiver is operating within the specified ratings.

Additional Research

Some further rules have been propounded by the Pinellas County Health Department

(Tampa-St. Petersburg area) in Florida. There, extensive tests have been conducted

by a health physicist, George McCall. They have resulted in a 3-hour radiation-safety

course which will be given to technicians in that county.

McCall's test results (unverified in other independent tests) indicate that there

may be dangers to service technicians from the neck of the picture tube during certain

adjustments. According to McCall, when the yoke is retracted, high-speed electrons

are deflected to the wall of the picture-tube neck, causing emission of a 1/4-inch-wide

beam of radiation around the circumference of the neck.

To avoid the possibility of this type of exposure, the Pinellas County Health

Department is recommending these additional rules:

1. From a local medical supply house, buy a small quantity of leaded plastic

sheeting, of the type used for dental X-ray aprons, The lightest-weight material

(1/4 millimeter) is okay. This should be draped over the set or tube during servicing.

(It provides protection from implosion, too.)

2. For protection of the eyes against both implosion and X-rays, wear a pair

of good safety glasses during servicing.

McCall explains that these precautions are particularly important if the voltage

is above the manufacturer's specified level - a condition which never should be

allowed to exist.

The "X-ray menace" recently was put into perspective by Dr. Lauriston Taylor,

president of the NCRP. Testifying before a Congressional committee, he said:

"Television equipment generally is made so as to reduce radiation to an unimportant

level, certainly for the general public and usually for the service man. Steps to

insure this include heavying-up of the glass, adding high-atomic-number materials

to the glass, placing metal barriers at strategic points in the set, enclosing the

set in a box, and so on. It takes very little material to attenuate any X-rays produced

in television equipment and it can be considered a blunder when something goes wrong

and this is not accomplished.

"It would be my guess that even working with the defective television sets, such

as those that have been publicized recently, there would be probably small risk

to the service man at a bench, primarily because of the small likelihood of any

appreciable portion of his body remaining in close proximity to the source of radiation.

This again is not to say it is good, but to point out that it might not be as bad

as some recent news stories have indicated ... The protective steps are so readily

simple that a rudimentary manual could give the user most, if not all, of the information

that he would need."

Color and Monochrome (B&W) Television

Articles

|

By David Lachenbruch

By David Lachenbruch